Interior wall coating with lasting fragrance and preparation method thereof

A technology of interior wall paint and fragrance, applied in the direction of coating, etc., can solve the problems of impure fragrance of paint, strong smell of paint, slow release of fragrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

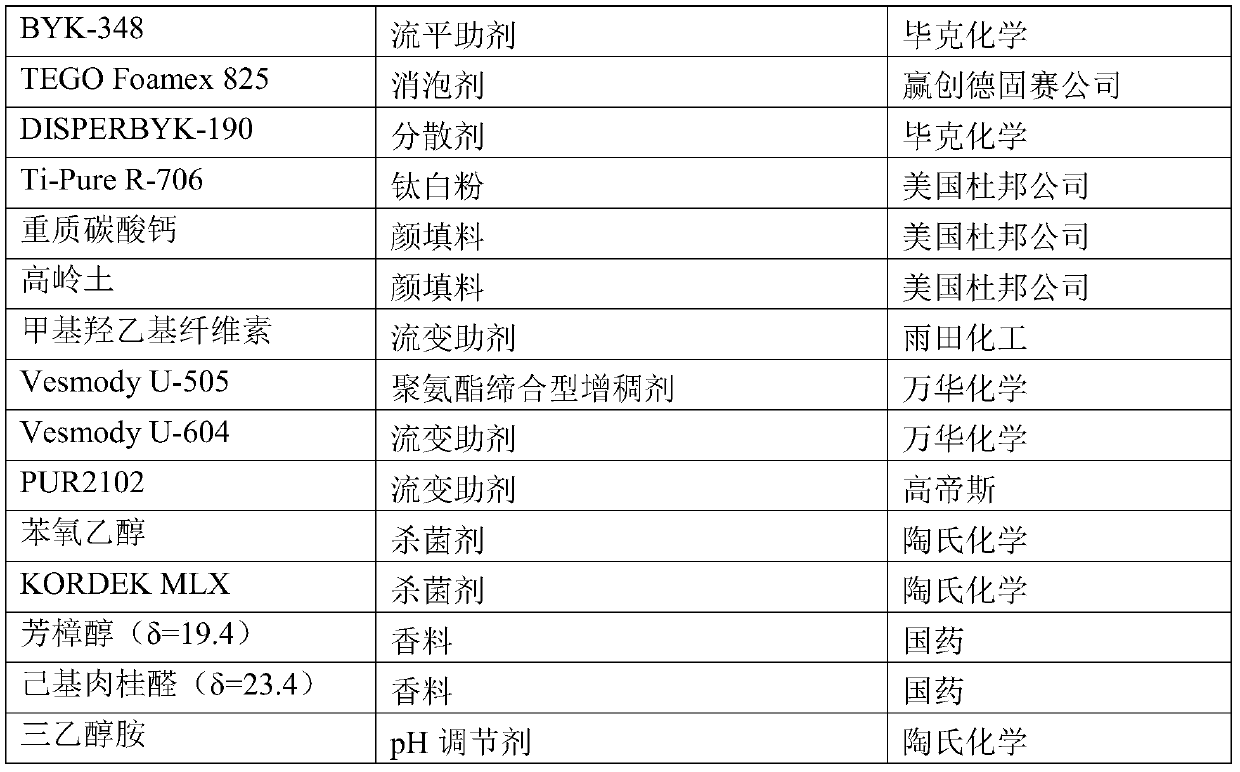

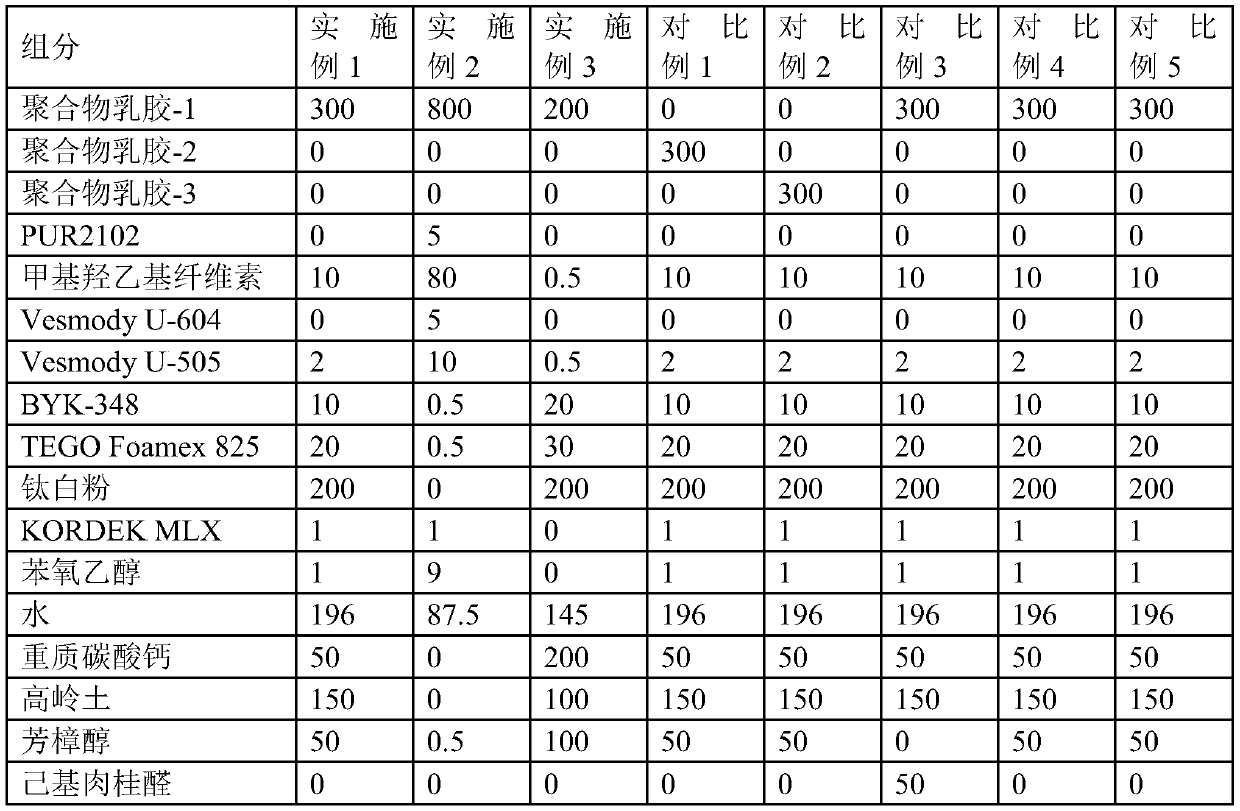

Examples

preparation example 1

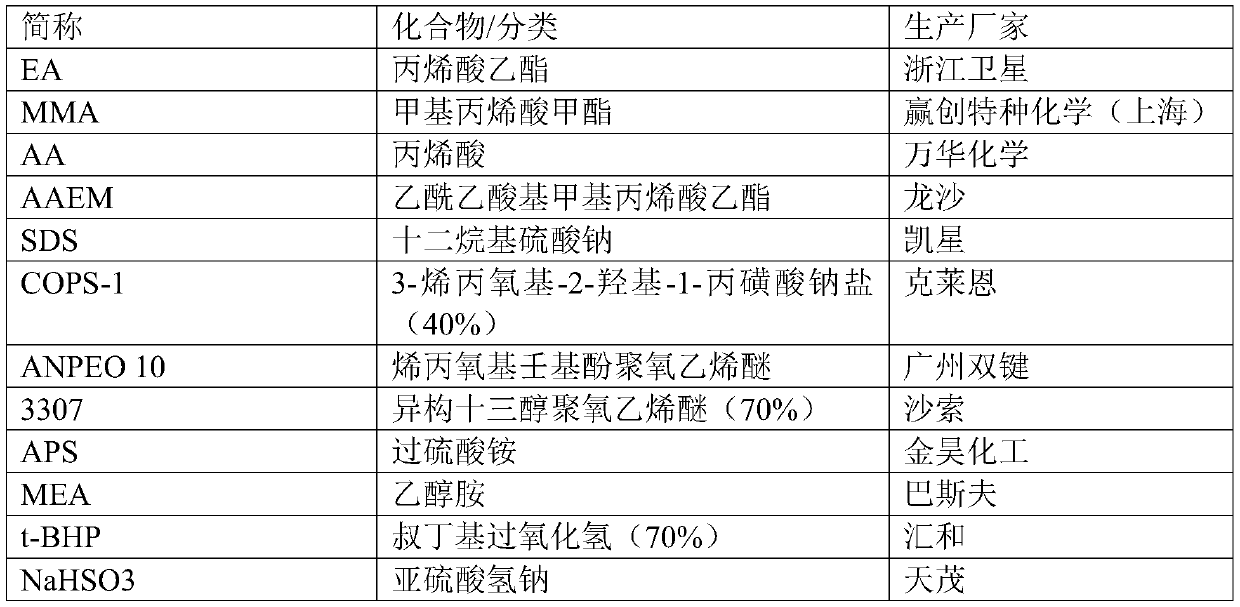

[0079] Preparation Example 1: Polymer Latex-1

[0080] A zero-added polymer latex-1 is prepared by the following process:

[0081] 1) Mix 6.6g of sodium lauryl sulfate, 5g of ANPEO10, 4g of COPS-1, 280g of deionized water, 145g of MMA, 800g of EA, 40g of AAEM, and 5g of AA to obtain a pre-emulsion (ME) ;

[0082] 2) 2gAPS and 45g water are mixed to obtain the dripping initiator solution;

[0083] 3) 3gAPS and 45g water are mixed to obtain the initiator solution at the bottom of the tank;

[0084] 4) Add 0.4g of sodium lauryl sulfate and 511g of deionized water into the reactor, stir and dissolve them fully and heat them to 85°C in a nitrogen environment. When the temperature in the reactor rises to 85°C, add 50g of Pre-emulsion (ME) and all the initiator solution at the bottom of the kettle are kept for 10 minutes;

[0085] 5) Control the temperature at 85°C, add the remaining pre-emulsion (ME) and the entire initiator solution dropwise at the same time, keep the temperatu...

preparation example 2

[0088] Preparation Example 2: Polymer Latex-2

[0089] A zero-addition polymer latex 2 is prepared by the following process:

[0090] 1) Mix 6.6g sodium lauryl sulfate, 4g COPS-1, 280g deionized water, 145g MMA, 800g EA, 40g AAEM, 5g AA to obtain a pre-emulsion (ME);

[0091] 2) 2gAPS and 45g water are mixed to obtain the dripping initiator solution;

[0092] 3) 3gAPS and 45g water are mixed to obtain the initiator solution at the bottom of the tank;

[0093] 4) Add 0.4g of sodium lauryl sulfate and 513g of deionized water into the reaction kettle, stir and dissolve them, and heat them to 85°C in a nitrogen environment. When the temperature in the reaction kettle rises to 85°C, add 50g of Pre-emulsion (ME) and all the initiator solution at the bottom of the kettle are kept for 10 minutes;

[0094]5) Control the temperature at 85°C, add the remaining pre-emulsion (ME) and the entire initiator solution dropwise at the same time, keep the temperature for 20 minutes after the d...

preparation example 3

[0097] Preparation Example 3: Polymer Latex-3

[0098] A zero-added polymer latex 3 was prepared by the following process:

[0099] 1) Mix 6.6g of sodium lauryl sulfate, 33g of ANPEO10, 4g of COPS-1, 280g of deionized water, 145g of MMA, 800g of EA, 40g of AAEM, and 5g of AA to obtain a pre-emulsion (ME) ;

[0100] 2) 2gAPS and 45g water are mixed to obtain the dripping initiator solution;

[0101] 3) 3gAPS and 45g water are mixed to obtain the initiator solution at the bottom of the tank;

[0102] 4) Add 0.4g of sodium lauryl sulfate and 523g of deionized water into the reactor, stir and dissolve them, and heat them to 85°C in a nitrogen environment. When the temperature in the reactor rises to 85°C, add 50g of Pre-emulsion (ME) and all the initiator solution at the bottom of the kettle are kept for 10 minutes;

[0103] 5) Control the temperature at 85°C, add the remaining pre-emulsion (ME) and the entire initiator solution dropwise at the same time, keep the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com