Quick-drying water-based paint

A water-based paint, quick-drying technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of slow drying speed and inconvenient construction, and achieve the goal of improving drying speed, accelerating drying speed, and accelerating volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0075] Preparation of acrylic modified epoxy resin:

[0076] Put 250g of epoxy resin E44 and 100mL of butanol solvent in a reaction vessel, stir and heat up to 80°C, add 3g of catalyst dimethylethanolamine, dropwise add a mixture of acrylic acid and p-methoxyphenol, acrylic acid and p-methoxyphenol In the mixture of base phenol: p-methoxyphenol content 1.5g, acrylic acid 50g, dropwise for about 30min, then raise the temperature to 105°C, measure the acid value at regular intervals until the acid value of the reaction system is lower than 20mgKOH / g , stop the reaction, remove the unreacted substances in vacuum to prepare acrylic modified epoxy resin.

preparation example 2

[0078] Add 200g of epoxy resin E44 into the reactor, raise the temperature to 75°C, add dropwise a mixture of 80g of acrylic acid, 2g of hydroquinone, and 2g of tetrabutylammonium bromide for about 1 hour, then raise the temperature to 95°C , heat preservation reaction for 5h, when the acid value of the reaction system is lower than 5mg / g, lower the reaction temperature, stop the reaction, at this time to obtain a solvent-based acrylic modified epoxy resin EA.

[0079] The acrylic modified epoxy resin EA of this preparation example (EA and the following EB are only for the convenience of distinguishing and narrating, and do not imply additional limitations to the acrylic modified epoxy resin itself), and secondary modification can also be carried out, for example, using cis Butenedioic anhydride is used as the main raw material, supplemented with an appropriate amount of accelerators, etc., and the resulting product can be regarded as "acrylic acid / maleene joint modified epoxy ...

Embodiment 1

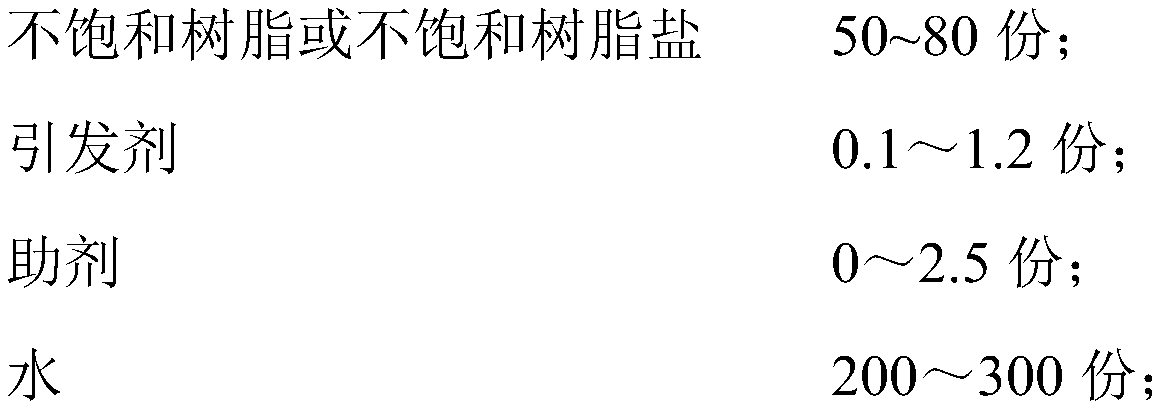

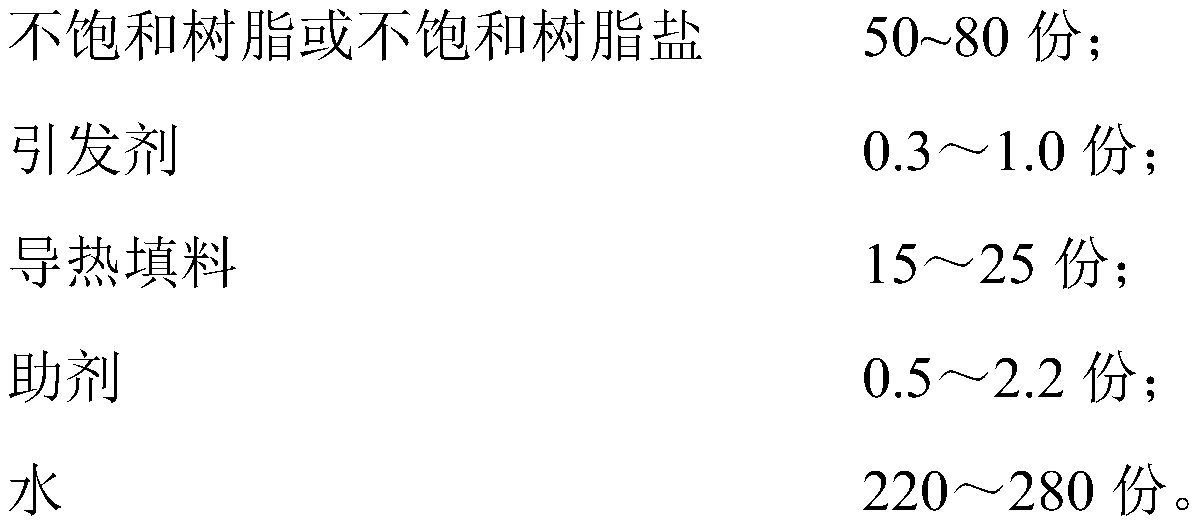

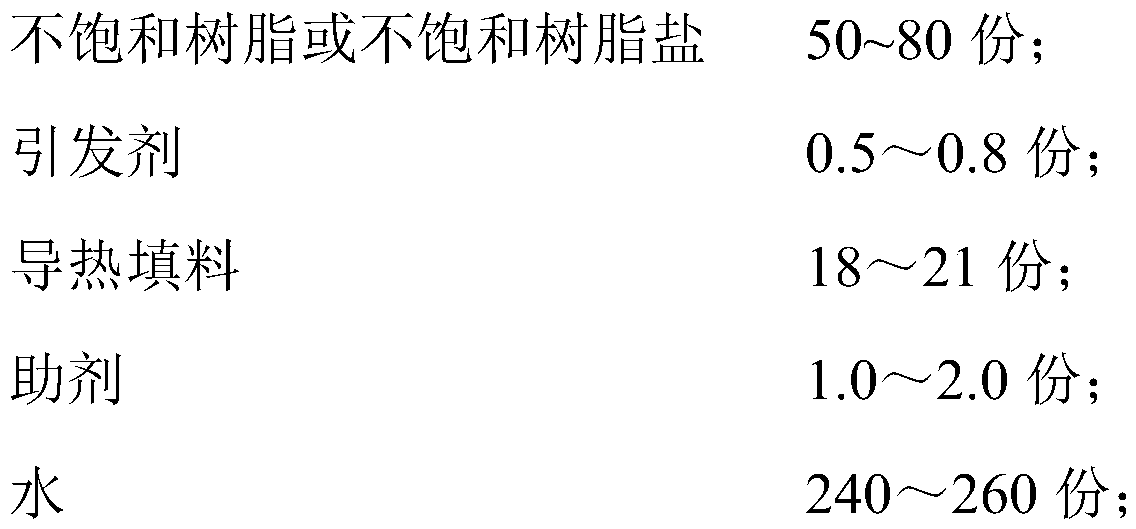

[0082] Adopt the acrylic acid modified epoxy resin that preparation example 1 obtains in the present embodiment, mix with other raw materials and obtain quick-drying water-based paint, each raw material comprises:

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap