Preparation method of multifunctional calotropis gigantean fiber blended yarn

A technology of horn gourd fiber and blended yarn, which is applied in fiber treatment, plant fiber, ultrasonic/sonic fiber treatment, etc. It can solve the problems of brittle fiber, low breaking strength and difficulty, and achieve soft air permeability and process operation. Simple, soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

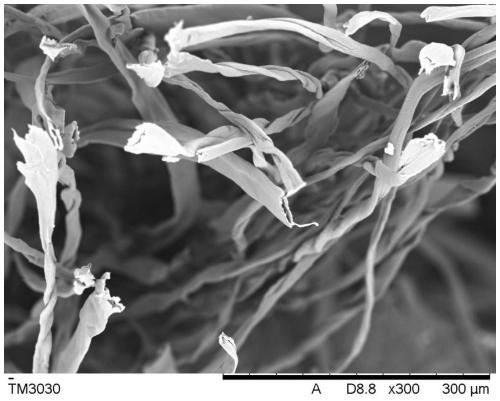

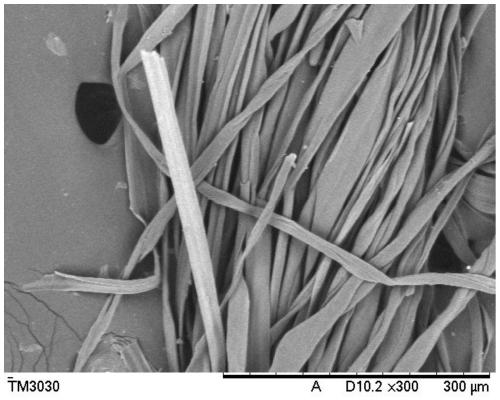

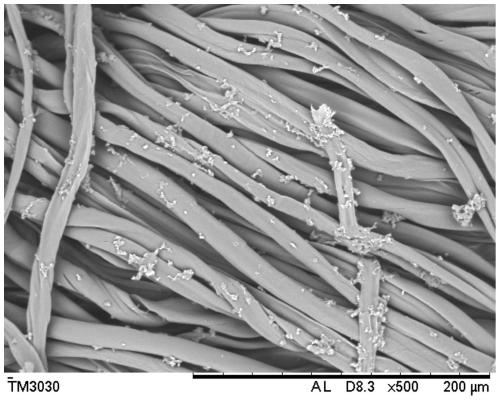

[0044] Such as Figure 1-6 Shown, the preparation method of a kind of multifunctional croissant melon fiber blended yarn that the present invention proposes, preparation method comprises the following steps:

[0045] Preparation of S1, horn gourd fiber blended yarn:

[0046] The cotton fiber is spun into combed sliver, and the combed sliver and the horn gourd fiber are mixed according to the mass ratio (2-6): (4-8), and the ingredients are mixed by multi-layer tiling; the mixed ingredients are sent to Cotton is opened on the FA006 plucking machine and processed into rolls on the FA1141A lapping machine; the cotton laps are carded into strips on the carding machine, and the raw sliver weight is 15-30g / 5m; the speed of the carding machine is 10-25m / min

[0047] Drawing process: 5-9 strands are merged in the first pass, the drafting ratio is 5-10 times, the evenness weight is 16-28g / 5m, and the stripping speed is 120-300m / min;

[0048] Secondary drawing process: 5-10 strands ar...

Embodiment 1

[0068] The preparation technology of multifunctional horn gourd fiber blended yarn, its concrete steps are as follows:

[0069] The cotton fiber is spun into a combed sliver, and then mixed with the modified horn gourd fiber according to the mass ratio of 3:7, and the ingredients are mixed by multi-layer tiling, and the mixed ingredients are sent to the FA006 type plucking machine to open the cotton, It is processed into rolls on the FA1141A lapping machine, and the cotton laps are carded into slivers on the carding machine. The carding machine has been improved to reduce multi-point and multiple strikes on fibers and prevent fiber breakage. The raw sliver weight is 25g / 5m and the speed is 14m / min, slow production; drawing process, 7 parallels in the first pass, 7 times the drafting ratio, 22g / 5m evenness weight, 260m / min delivery speed, slow production; 8 parallels in the second pass, drafting The multiple is 7 times, the evenness basis weight is 20g / 5m, the sliver delivery ...

Embodiment 2

[0075] The preparation technology of multifunctional horn gourd fiber blended yarn, its concrete steps are as follows:

[0076] The cotton fiber is spun into a combed sliver, and then mixed with the modified croissant melon fiber according to the mass ratio of 4:6, and the ingredients are mixed by multi-layer flat laying, and the mixed ingredients are sent to the FA006 type plucking machine to open the cotton, It is processed into rolls on the FA1141A lapping machine, and the cotton laps are carded into slivers on the carding machine. The carding machine has been improved to reduce multi-point and multiple strikes on fibers and prevent fiber breakage. / min, slow production; drawing process, 8 parallels in the first pass, 7 times the drafting ratio, 16g / 5m evenness weight, 220m / min delivery speed, slow production; 8 parallels in the second pass, drafting The multiple is 7 times, and the evenness basis weight is 14g / 5m, the sliver delivery speed is 220m / min, and the production i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com