Cotton-feeling knitted fabric

A technology of knitted fabrics and cotton feel, applied in the field of warp knitted fabrics, can solve the problems of unsuitable sports fabrics, poor air permeability, and easy detachment of coils, etc., to achieve highly consistent appearance and feel, stable warp knitted structure, and not easy The effect of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

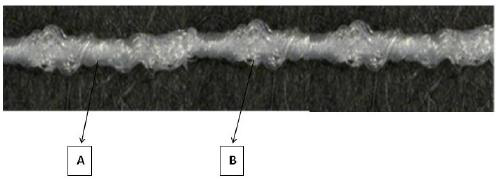

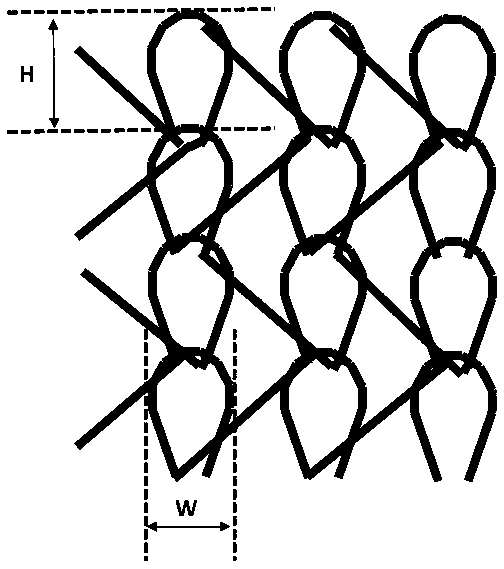

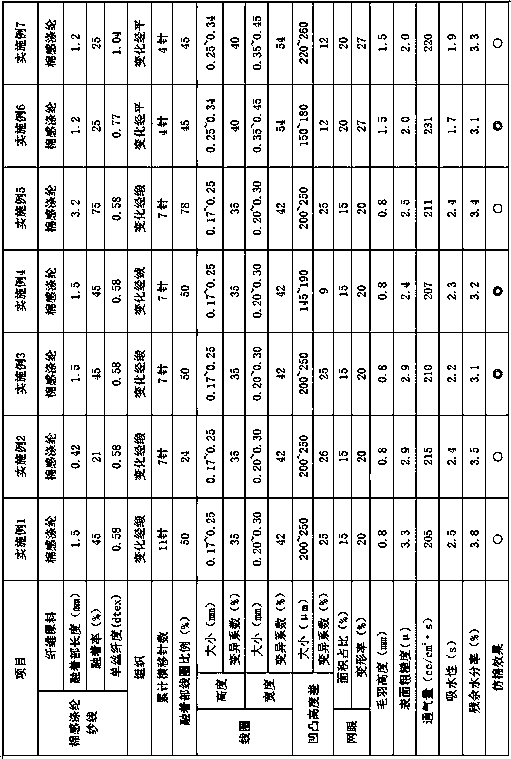

[0093] On the HKS4 tricot warp knitting machine (machine number E28, machine width 136 inches), select 75D-144f-cotton-feeling polyester filament (manufactured by Toray Synthetic Fiber (Nantong) Co., Ltd., with a fusion degree of 45%. The length of the wearing part is 1.5mm), using the front and rear two combs to change the warp and satin weave to weave, and the front and rear two combs have accumulated 11 stitches to make the gray cloth, and then through scouring, dyeing, fluffing and other processing to obtain the gray cloth of the present invention. Cotton-feeling knitted fabrics, see Table 1 for details.

[0094] Among them, scouring: caustic soda 2g / L, scouring agent 2g / L, 90℃×20min, liquor ratio 1:20; dyeing: 130℃×30min, reduction cleaning: 80℃×20min.

Embodiment 2

[0096] Select 75D-144f-cotton-feeling polyester filament (manufactured by Toray Synthetic Fiber (Nantong) Co., Ltd., the degree of fusion is 21%, and the length of the fusion part is 0.42mm), and use two combs at the front and back to weave with changing warp and satin weave , the accumulative transverse movement of the front and back two combs is 7 needles to obtain a gray cloth, and the rest are the same as in Example 1 to obtain the cotton-feeling knitted fabric of the present invention, see Table 1 for details.

Embodiment 3

[0098] Select 75D-144f-cotton-feeling polyester filament (manufactured by Toray Synthetic Fiber (Nantong) Co., Ltd., the degree of fusion is 45%, and the length of the fusion portion is 1.5mm) as raw material, and the rest are the same as in Example 2 to obtain the present invention The cotton-feeling knitted fabric, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com