Coal-fired power generation unit single-tank molten salt thermocline heat storage system and method

A technology of generator set and heat storage system, which is applied in the steam generation method using heat carrier, heat storage equipment, type of heat exchanger, etc., can solve the problem that affects the continuous and stable operation of the steam turbine power generation system, and it is difficult to guarantee the heat on the user side in real time. , The safety requirements of generator sets are getting higher and higher, so as to achieve the effect of realizing rapid response, improving flexibility and peak regulation ability, and improving the ability of long-term stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

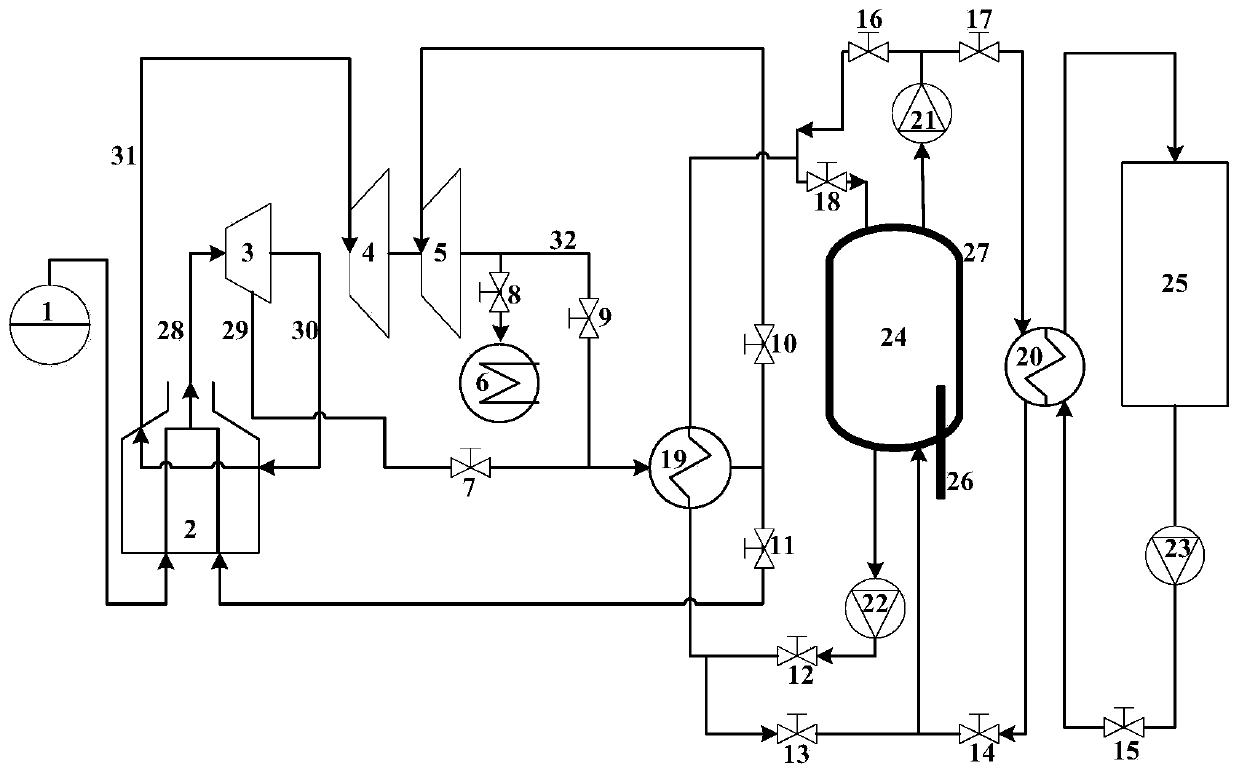

[0035] refer to figure 1 , a single-tank molten salt thermocline layer heat storage system for a coal-fired generator set according to the present invention, comprising steam entering a boiler 2 through a steam drum 1 for heating and then entering a high-pressure cylinder 3 of a steam turbine, connecting the steam extraction port of the high-pressure cylinder 3 of the steam turbine to the The first heat exchanger 19 communicates with the steam extraction pipe 29 of the high-pressure cylinder, and the reheat steam pipe 31 communicates the reheat steam of the boiler 2 with the medium-pressure cylinder 4 of the steam turbine. device 6; the steam inlet of the low-pressure cylinder 5 of the steam turbine is also connected with the high-temperature steam outlet of the first heat exchanger 19, and the exhaust port of the low-pressure cylinder 5 of the steam turbine is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com