Tobacco shreds containing hyaluronic acid composition and preparation method thereof

A technology of hyaluronic acid and composition, which is applied in the field of shredded tobacco containing hyaluronic acid composition and its preparation, which can solve problems such as dryness and discomfort, strong irritation, and thick smoke, so as to reduce irritation and dry feeling, improve Taste, reduce the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

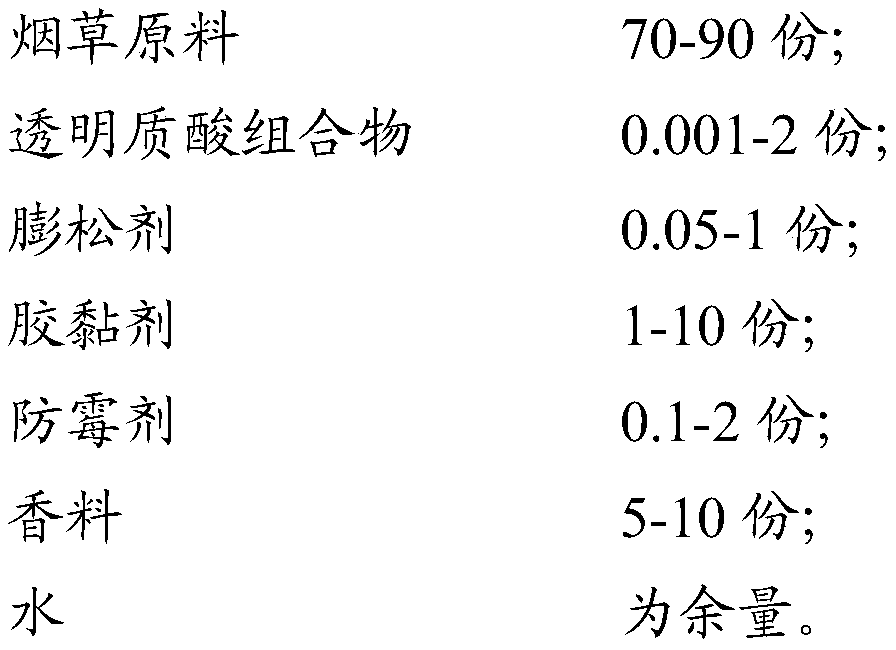

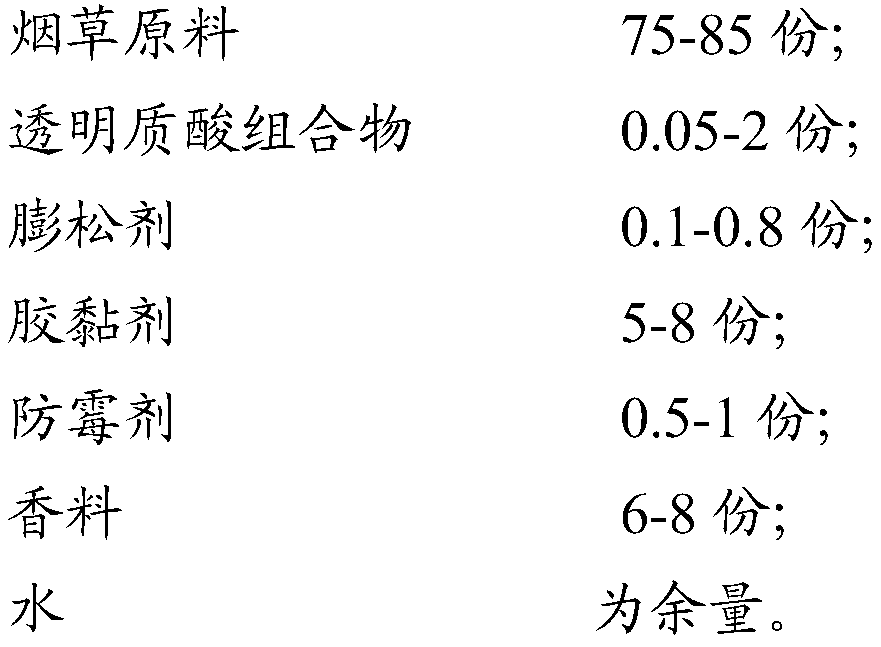

Method used

Image

Examples

preparation example Construction

[0063] The present application also relates to a method for preparing shredded tobacco containing a hyaluronic acid composition, comprising the following steps:

[0064] Step 1: taking tobacco raw material to remove thick stems, drying, crushing, shredding, and making tobacco raw material a;

[0065] Step 2: Mix the leavening agent, adhesive and anti-mold agent uniformly in proportion, dissolve them in water, and prepare the feed liquid for subsequent use;

[0066] Step 3: mix sodium hyaluronate and zinc hyaluronate in proportion, put them into water for stirring, and prepare an aqueous solution of a hyaluronic acid composition;

[0067] Step 4: Spray the feed liquid and the aqueous solution of the hyaluronic acid composition into the tobacco raw material a to obtain the tobacco raw material b;

[0068] Step 5: performing secondary drying and cooling on the tobacco raw material b to obtain tobacco raw material c;

[0069] Step 6: Add spices to the tobacco raw material c to o...

Embodiment 1

[0080] Take 70g of tobacco leaves and remove the thick stalks with leaf thresher light equipment to obtain tobacco raw materials with a stalk rate of no more than 2%, then dry, crush and shred them, and then weigh 0.05g of leavening agent and 1g of guar gum , 0.1g fumaric acid, dissolved in 10g deionized water to make a feed liquid for subsequent use, then take 0.003g sodium hyaluronate and 0.002g zinc hyaluronate in proportion to be dissolved in 13g deionized water and stir evenly to obtain hyaluronic acid Composition aqueous solution; then the material liquid and the hyaluronic acid composition aqueous solution are evenly sprayed in the tobacco raw material, and after its moisture content reaches 18%, stand for a period of time and carry out secondary drying and cooling to it, measure its moisture content, and wait for it to drop After reaching 15%, 5.8g of tetramethylpyrazine is added to the tobacco raw material to obtain finished shredded tobacco.

[0081] Embodiment 2-Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com