Automatic bone drilling device

An automatic drill and drill clamp technology, applied in the field of medical equipment, can solve the problems of limited load, large mass, and long-term stability of the mechanical arm, and achieve the effect of weight reduction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

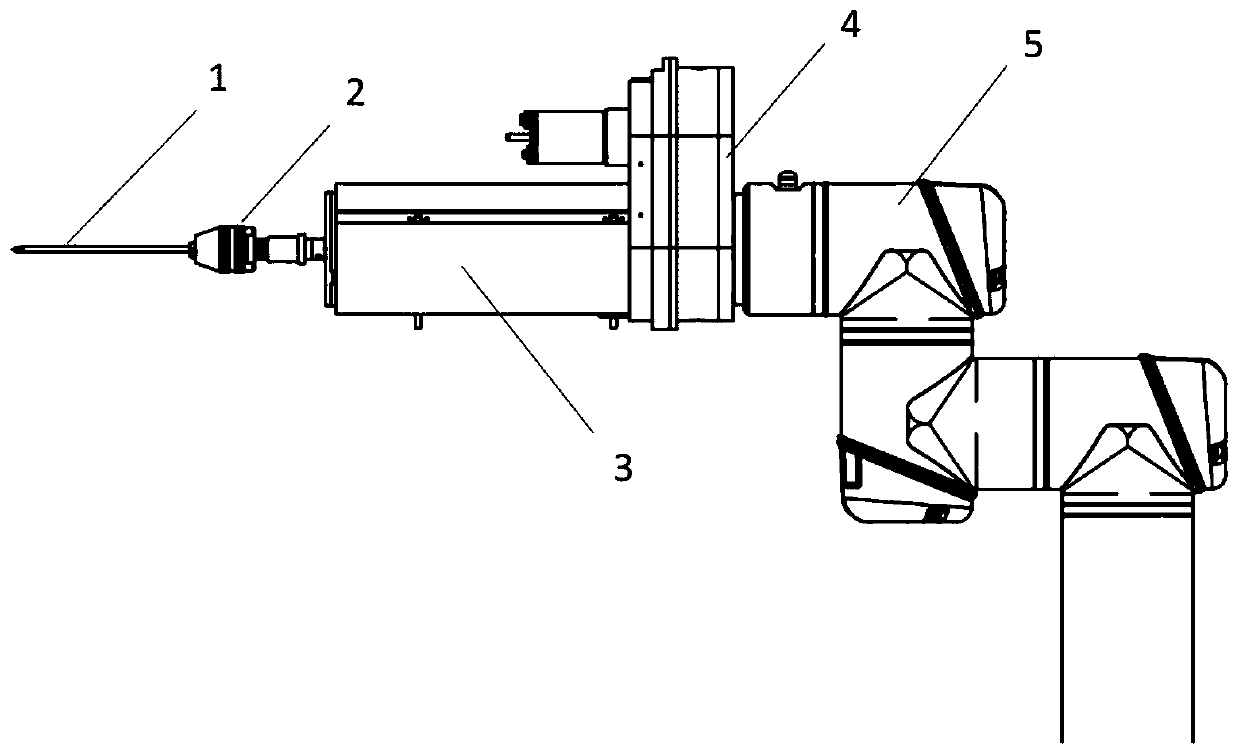

[0045] figure 1 It is the structural diagram of the automatic bone drilling device, such as figure 1 As shown, the automatic bone drilling device of the present invention includes a Kirschner wire 1, a rotating mechanism 2 and a feeding mechanism 3, the feeding mechanism 3 is fixedly connected with the mechanical arm 5 through a transition piece 4, and the rotating mechanism 2 is connected by screws (not limited to this Connection) On the outer cylinder 3-15 of the feed mechanism 3, the Kirschner wire 1 is fixed on the drill clip 2-9 of the rotary mechanism 2.

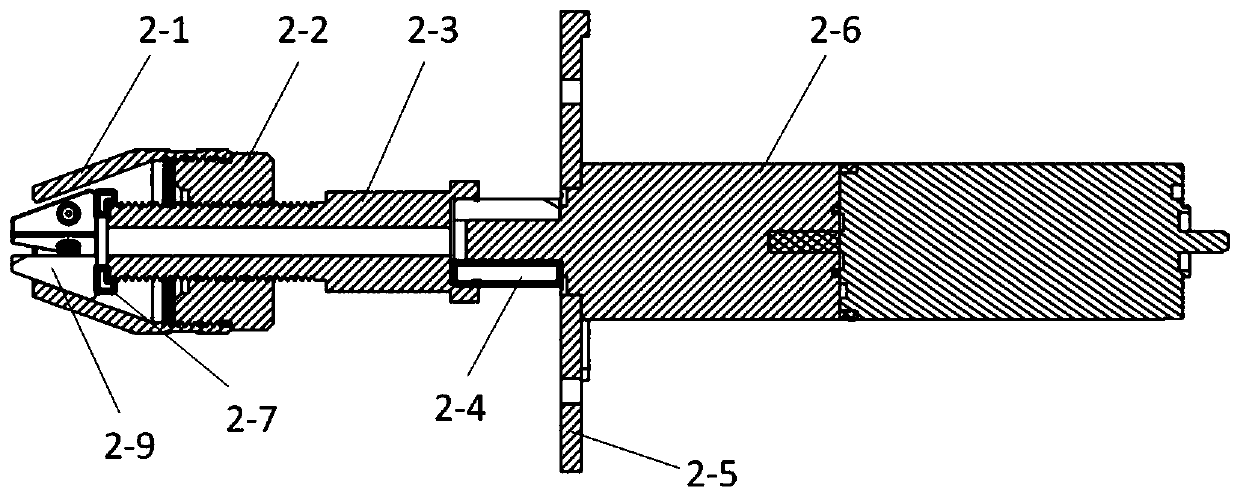

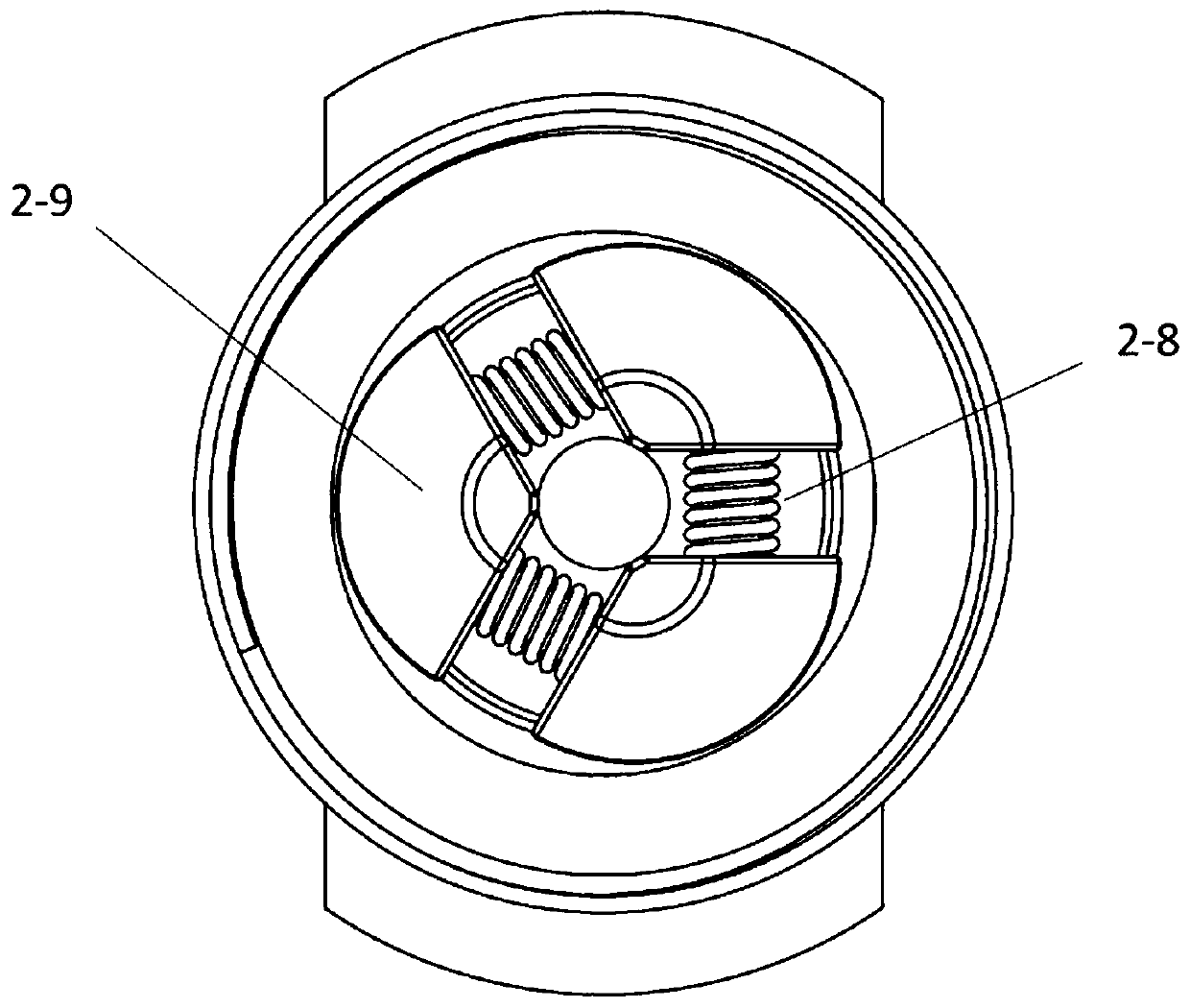

[0046] figure 2 is a sectional view of the rotation mechanism of the automatic bone drilling device, such as figure 2 As shown, the rotating mechanism 2 includes a rotating motor 2-6, a connecting piece 2-4, a threaded push rod 2-3, an intermediate threaded rod 2-2, a fixed sleeve 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com