Oil-water separation process for high-oil-content emulsified produced water

A technology for oil-water separation and produced water, applied in separation methods, liquid separation, mining wastewater treatment, etc., can solve problems such as damage to air flotation treatment equipment, scaling, etc., to reduce the number of dosing stations and management points, reduce Oil content, the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

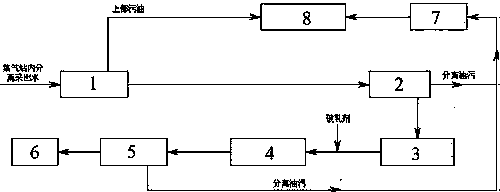

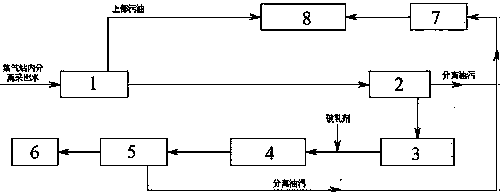

[0032] This example provides an oil-water separation process for highly oily emulsified produced water. After the produced water undergoes gas-water separation at the gas-gathering station, the produced water undergoes the first oil-water separation in the gas-gathering station, and then the produced water treatment station conducts the first oil-water separation process. For the second oil-water separation and the third oil-water separation, the produced water after the third oil-water separation enters the produced water treatment system 6 of the treatment station for treatment and reinjection, and the waste oil separated from oil and water each time is sent to the waste oil station for treatment.

[0033] In order to solve the problems of demulsification and oil-water separation, the present invention pre-treats the incoming water through the oil-water separation process of high oil-containing emulsified produced water at the front end of the produced water treatment system 6...

Embodiment 2

[0036] This example provides an oil-water separation process for highly oily emulsified produced water. After the produced water undergoes gas-water separation at the gas-gathering station, the produced water undergoes the first oil-water separation in the gas-gathering station, and then the produced water treatment station conducts the first oil-water separation process. For the second oil-water separation and the third oil-water separation, the produced water after the third oil-water separation enters the produced water treatment system 6 of the treatment station for treatment and reinjection, and the waste oil separated from oil and water each time is sent to the waste oil station for treatment.

[0037] Among them, after the gas-water separation of the produced water in the gas-gathering station, the separated natural gas is collected and transported through the process pipeline, and the extracted produced water is temporarily stored in the buried sewage tank 1 of the gas-g...

Embodiment 3

[0040] This example provides an oil-water separation process for highly oily emulsified produced water. After the produced water undergoes gas-water separation at the gas-gathering station, the produced water undergoes the first oil-water separation in the gas-gathering station, and then the produced water treatment station conducts the first oil-water separation process. For the second oil-water separation and the third oil-water separation, the produced water after the third oil-water separation enters the produced water treatment system 6 of the treatment station for treatment and reinjection, and the waste oil separated from oil and water each time is sent to the waste oil station for treatment.

[0041] Among them, the produced water after the first oil-water separation is transported to the produced water treatment station, and the second oil-water separation is carried out through the oil-water separator 2 of the treatment station, and the separated waste oil is stored in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com