Sludge hopper anti-blocking device for sludge drying treatment

A sludge drying and anti-clogging technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve problems such as affecting the normal operation of sludge drying treatment, different sludge moisture content, sludge clogging, etc., to avoid Clogging, increasing fluidity, avoiding the effect of hopper clogging

Inactive Publication Date: 2020-05-08

扬州市国翔智慧机电设备有限公司

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the sludge bridging phenomenon easily occurs due to the different water content of the sludge after it enters the hopper in the prior art, causing the sludge to fail to slide down naturally inside the hopper and blockage, which affects the drying of the sludge. Due to the problem of normal operation of sludge treatment, a sludge hopper anti-clogging device for sludge drying treatment is proposed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

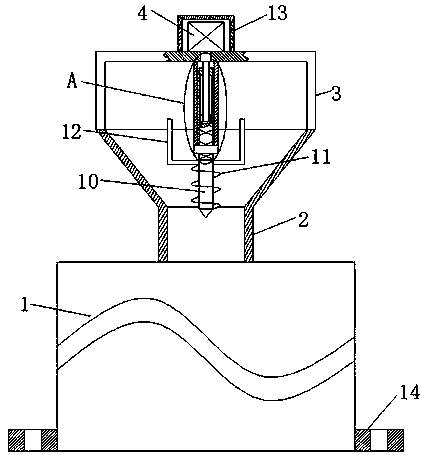

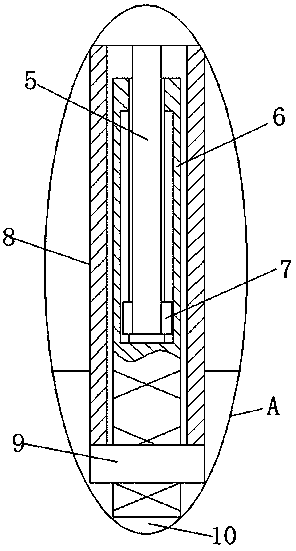

The invention discloses a sludge hopper anti-blocking device for sludge drying treatment. The device comprises a drying machine and a material hopper fixedly arranged at the upper end of the drying machine, wherein the upper end of the material hopper is fixedly connected with a U-shaped plate, a driving motor is fixedly arranged at the upper end of the U-shaped plate, the output end of the driving motor is rotationally connected with a rotating rod through a coupler, the lower end of the rotating rod penetrates through the U-shaped plate and extends downwards, the rod wall of the rotating rodis rotationally connected with the U-shaped plate through a rolling bearing, a reciprocating lead screw is arranged below the rotating rod, a groove matched with the rotating rod is formed in the upper end of the reciprocating lead screw, the lower end of the rotating rod extends into the groove, two symmetrically-arranged sliding blocks are fixedly connected to the lower end of the rod wall of the rotating rod, sliding grooves matched with the sliding blocks are formed in the side wall of the groove, and the reciprocating lead screw is movably sleeved with a bush. With the device of the invention, sludge in the material hopper can be effectively stirred and dredged, so that sludge bridging and blocking in the material hopper can be avoided, and people can use the device conveniently.

Description

technical field [0001] The invention relates to the technical field of sludge treatment equipment, in particular to a sludge hopper anti-clogging device for sludge drying treatment. Background technique [0002] Sludge is the product of sewage treatment. It is an extremely complex heterogeneous body composed of organic debris, bacterial cells, inorganic particles, colloids, etc. The main characteristics of sludge are high water content, high organic matter content, and easy It is rotten and smelly, and the particles are finer, the specific gravity is smaller, and it is in a gel-like liquid state. It is a thick substance between liquid and solid. [0003] Sludge needs to be dried during the treatment process. Generally, sludge is dried by a sludge dryer. During the drying process, the sludge first needs to enter the dryer through the hopper, but after entering the hopper, the sludge , due to the different water content of the sludge, the phenomenon of sludge bridging is pron...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/12

CPCC02F11/12

Inventor 不公告发明人

Owner 扬州市国翔智慧机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com