Air-entraining type polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of air-entraining polycarboxylate water-reducing agent and its preparation, can solve the problems of incompatibility of air-entraining agent, low over-solubility, affecting product performance and concrete performance, etc. Achieve important social and economic significance, high air entrainment and strong foam stabilization, avoid compatibility and delamination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

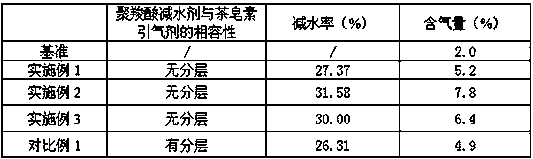

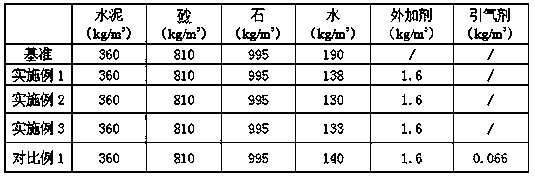

Examples

Embodiment 1

[0019] The components and mass ratios of the air-entraining polycarboxylate water reducer provided in the examples of the present invention are: 40 parts of polyether macromonomer, 10 parts of vinyl small monomer, 2 parts of tea saponin, 0.1 part of catalyst , 2 parts of initiator, and the rest are composed of water.

[0020] S101: Mix 5 parts of vinyl small monomer, 2 parts of tea saponin and 0.1 part of catalyst into a four-necked flask, and react at 100°C for 4 hours to prepare a polymerization-active tea saponin intermediate monomer;

[0021] S102: Mix the tea saponin intermediate monomer, 40 parts of polyether macromonomer and water according to the amount and put them into a four-necked flask, and add 5 parts of vinyl small monomer solution and 2 parts of initiator dropwise at 35°C Solution, trigger monomer polymerization, add dropwise for 2 hours, and keep warm at 35°C for 2 hours to obtain the mother liquor of air-entraining polycarboxylate superplasticizer;

[0022] ...

Embodiment 2

[0024] The components and mass ratios of the air-entraining polycarboxylate water reducer provided in the embodiment of the present invention are: 30 parts of polyether macromonomer, 20 parts of vinyl small monomer, 10 parts of tea saponin, 0.5 part of catalyst , 6 parts of initiator, and the rest are composed of water.

[0025] S101: Mix 10 parts of vinyl small monomer, 10 parts of tea saponin and 0.5 part of catalyst into a four-necked flask, and react at 120°C for 6 hours to prepare a polymerization-active tea saponin intermediate monomer;

[0026] S102: Mix the tea saponin intermediate monomer, 30 polyether macromonomer and water according to the amount and put them into a four-necked flask, and add 10 parts of vinyl small monomer solution and 6 parts of initiator solution dropwise at 60°C , initiate monomer polymerization, add drop time for 3 hours, and keep warm at 35°C for 1.5 hours to obtain the mother liquor of air-entraining polycarboxylate superplasticizer;

[0027...

Embodiment 3

[0029] The components and mass ratios of the air-entraining polycarboxylate water reducer provided in the examples of the present invention are: 20 parts of polyether macromonomer, 15 parts of vinyl small monomer, 5 parts of tea saponin, and 0.3 part of catalyst , 4 parts of initiator, and the rest are composed of water.

[0030] S101: Mix 5 parts of vinyl small monomer, 5 parts of tea saponin and 0.3 part of catalyst into a four-necked flask, and react at 80°C for 8 hours to prepare a polymerization-active tea saponin intermediate monomer;

[0031] S102: Mix the intermediate monomer of tea saponin, 20 parts of polyether macromonomer and water according to the amount and add them into a four-necked flask, and add 10 parts of vinyl small monomer solution and 4 parts of initiator dropwise at a temperature of 45°C Solution, trigger monomer polymerization, add dropwise for 3 hours, keep warm at 35°C for 2 hours, and then get air-entraining polycarboxylate superplasticizer mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com