Glass frosting liquid and its preparation method and application

A technology of glass and frosting, which is applied in the direction of chemical instruments and methods, surface etching compositions, etc., can solve the problems of uneven glass corrosion, harmfulness to human body, high risk of HF, etc., and achieve synergistic corrosion effect and no harm to human body. hazards and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

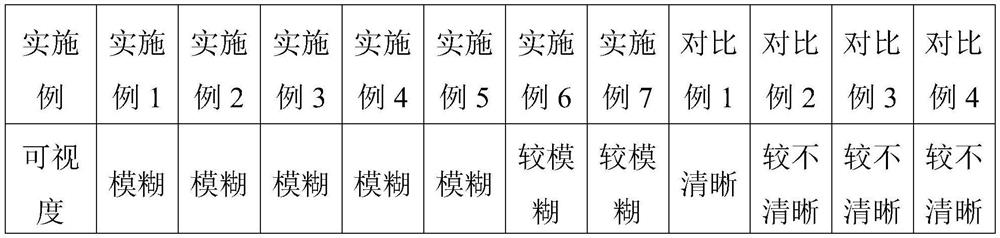

Examples

preparation example Construction

[0033] A preparation method for glass frosting liquid, comprising the following steps:

[0034] Molten metal salt to obtain molten salt; add phosphate, inorganic alkali, alkaline additives and adsorbent to the molten salt to obtain glass frosting solution;

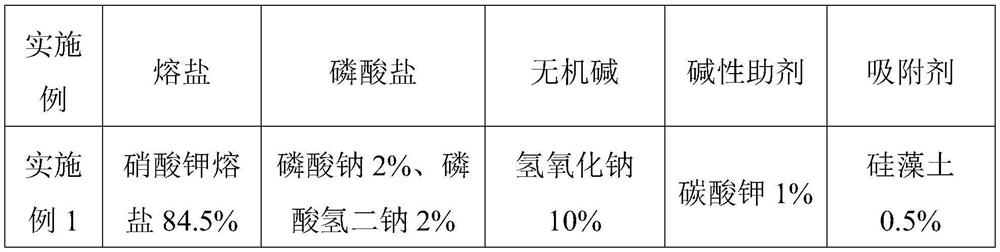

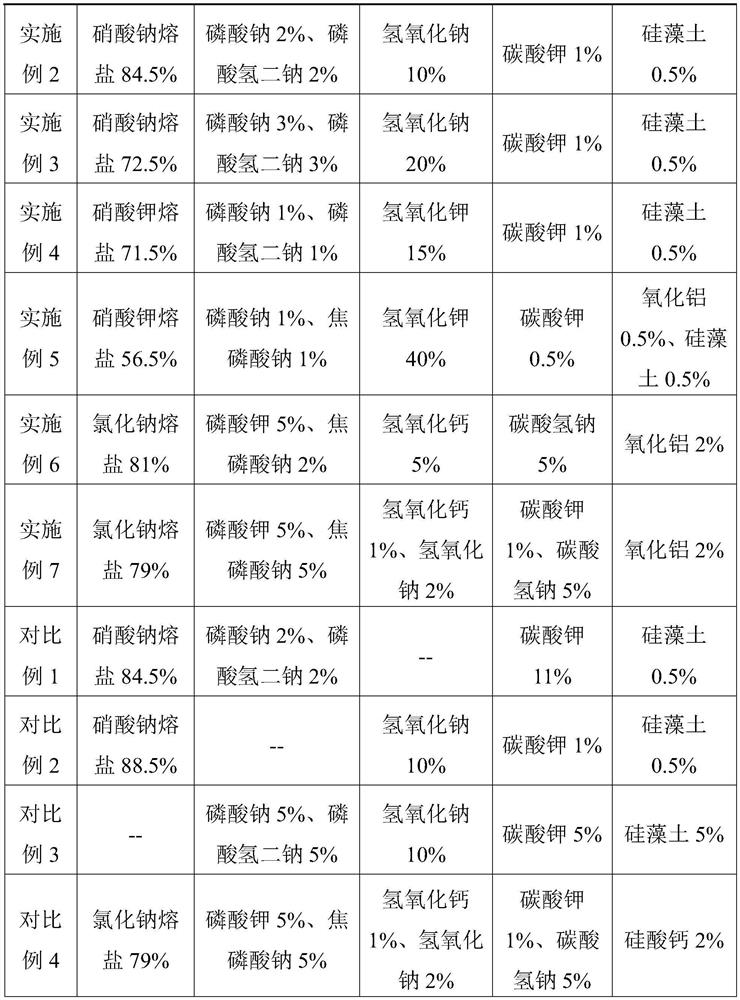

[0035] Wherein, the addition of each component accounts for the mass percent of described glass frosting liquid respectively:

[0036] Phosphate 0.5%-10%, inorganic alkali 0.51%-50%, alkaline additive 0.2%-5%, adsorbent 0.1%-5%, molten salt 30%-98.69%;

[0037] The metal salt is selected from at least one of potassium nitrate, sodium nitrate and sodium chloride, and the adsorbent is selected from at least one of diatomaceous earth and aluminum oxide.

[0038] The invention first melts the metal salt to obtain the molten salt, and provides a high-temperature environment; then adds a specific proportion of inorganic alkali and alkaline additives to the molten salt, and utilizes the alkali and SiO in the glass to 2 and Al ...

Embodiment 1

[0065] This embodiment provides a glass frosting solution and its preparation method and application.

[0066] (1) The preparation method of glass frosting liquid in the present embodiment, comprises the following steps:

[0067] Melt potassium nitrate to obtain potassium nitrate molten salt; add sodium phosphate 2%, disodium hydrogen phosphate 2%, sodium hydroxide 10%, potassium carbonate 1% and diatomaceous earth 0.5% to potassium nitrate molten salt, potassium nitrate molten salt The content is 84.5%, and the glass frosting liquid is obtained.

[0068] (2) Preparation of frosted glass:

[0069] Clean the glass after CNC and polishing; prepare the glass frosting solution according to the preparation method of the above glass frosting solution; preheat the glass at 300°C for 20 minutes; soak the preheated glass in the glass frosting solution Frosting treatment was carried out for 10 minutes in the middle of the frosting treatment; the glass after frosting treatment was ultr...

Embodiment 2

[0071] This embodiment provides a glass frosting solution and its preparation method and application.

[0072] (1) The preparation method of glass frosting liquid in the present embodiment, comprises the following steps:

[0073] Melt sodium nitrate to obtain sodium nitrate molten salt; add sodium phosphate 2%, disodium hydrogen phosphate 2%, sodium hydroxide 10%, potassium carbonate 1% and diatomaceous earth 0.5% to sodium nitrate molten salt, sodium nitrate molten salt The content is 84.5%, and the glass frosting liquid is obtained.

[0074] (2) Preparation of frosted glass:

[0075] Clean the glass after CNC and polishing; prepare the glass frosting solution according to the preparation method of the above glass frosting solution; preheat the glass at 300°C for 20 minutes; soak the preheated glass in the glass frosting solution Frosting treatment was carried out for 10 minutes in the middle of the frosting treatment; the glass after frosting treatment was ultrasonically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com