Method and device for preparing low-carbon olefin from petroleum hydrocarbon

A technology of low-carbon olefins and petroleum hydrocarbons, which is applied in the direction of hydrocarbon cracking, petroleum industry, and hydrocarbon oil treatment, etc., and can solve problems such as low yield of low-carbon olefins, insufficient crude oil gasification, and easy coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment is used to provide a device for producing light olefins by vacuum cracking of petroleum hydrocarbons.

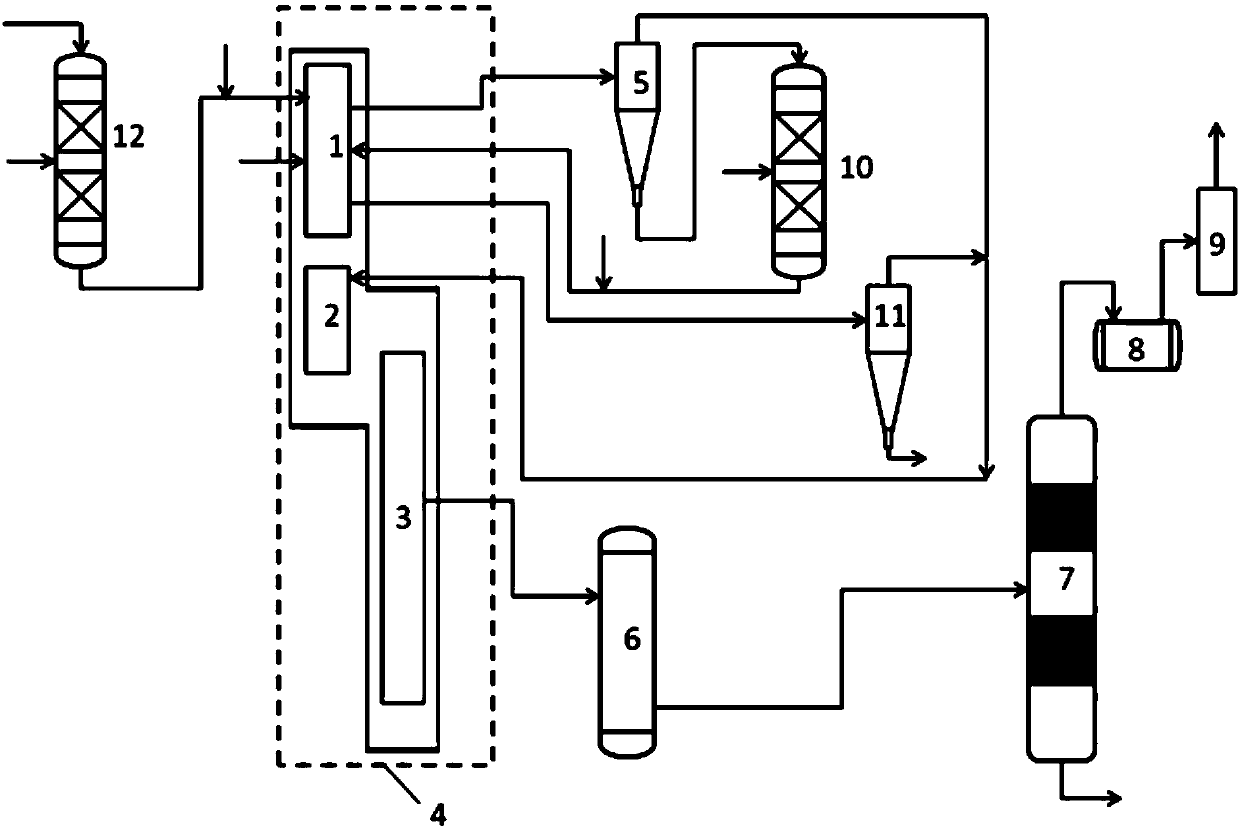

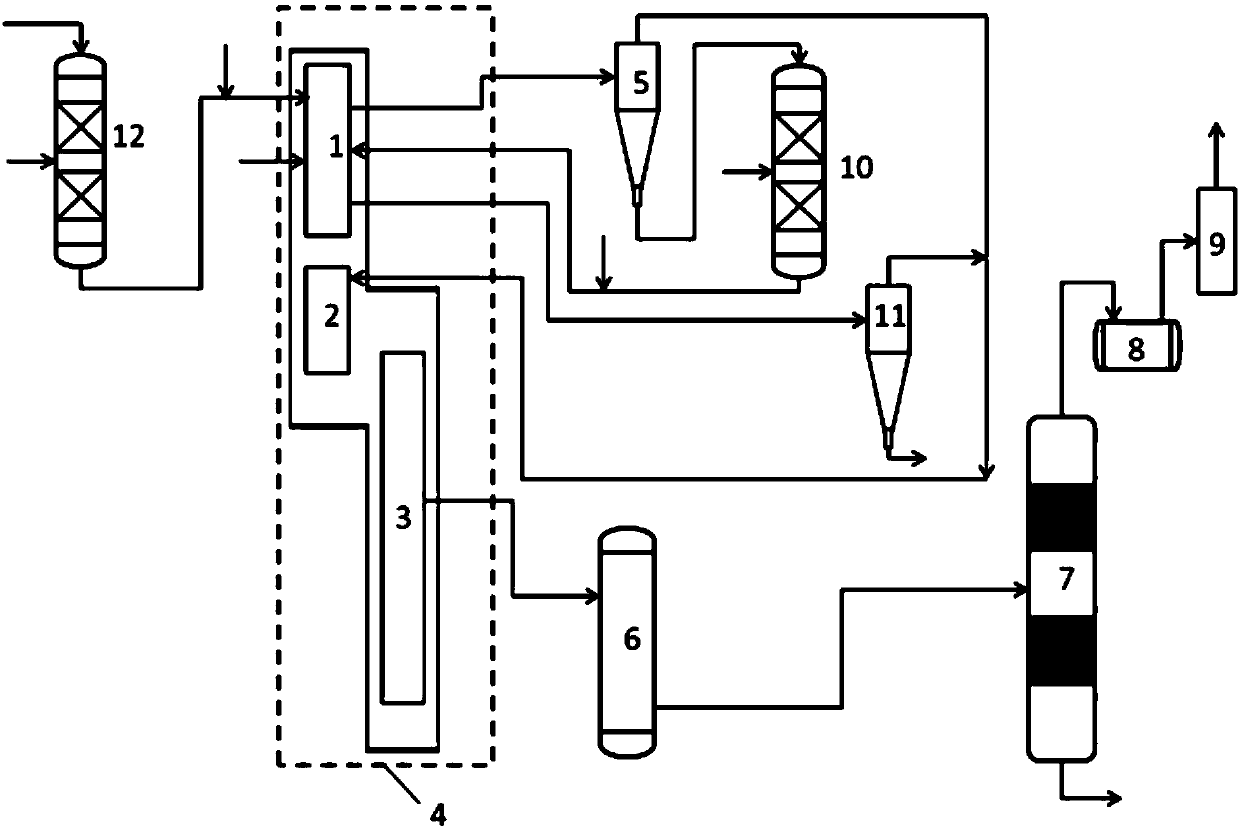

[0066] Such as figure 1As shown, the device includes a hydrogenation unit, a cracking unit connected to the hydrogenation unit, a heat exchange unit connected to the cracking unit, a separation unit connected to the heat exchange unit, and a decompression unit connected to the separation unit.

[0067] In this embodiment, the hydrogenation unit is the first hydrogenation reactor 12 .

[0068] The cracking unit includes a cracking furnace 4, a first cyclone separator 5, a second hydrogenation reactor 10 and a second cyclone separator 11, and the cracking furnace 4 includes a convection section first tube group 1 and a convection section arranged in sequence along the fluid direction. The second tube group 2 and the radiation section 3 connected to the second tube group 2 of the convection section. The outlet of the first hydrogenation reactor 12 is co...

Embodiment 2

[0072] This embodiment is used to provide a kind of method that adopts petroleum hydrocarbon to prepare light olefin, and this method comprises:

[0073] (1) Send the dehydrated and desalted crude oil to the first hydrotreater for hydroprocessing to obtain refined crude oil. The catalyst used is Co-Ni-Mo / Al 2 o 3 , the hydrogenation temperature is 270°C, the hydrogenation pressure is 2.6MPa, the hydrogen-to-oil ratio is 3.0, and the volumetric space velocity of crude oil is 2.0h -1 , The hydrogenation rate of monoene is 95%. The hydrotreated refined crude oil is mixed with naphtha to form a first mixture, wherein the weight ratio of refined crude oil to naphtha is 90:10.

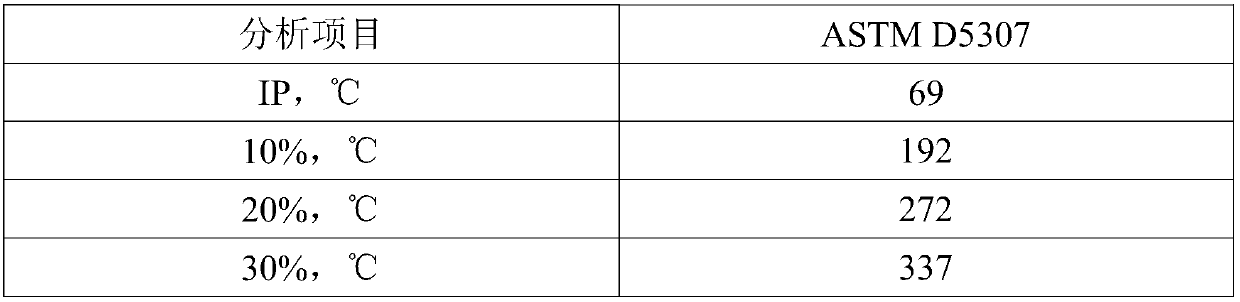

[0074] (2) The first mixture is preheated in the first pipe group 1 of the convection section of the cracking furnace 4, and mixed with superheated steam for gasification to obtain the gasified first mixture, and the weight ratio of superheated steam to the first mixture is 0.75: 1. The gasified first m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap