A kind of sludge waste bacterial stick derived solid fuel and preparation method thereof

A technology of solid fuel and waste fungus sticks, which is applied in the field of comprehensive utilization of solid waste resources, can solve problems such as environmental pollution hazards, and achieve the effects of improving porosity, low efficiency and lowering the temperature of burning embers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the solid fuel derived from the sludge waste bacteria rod comprises the following steps:

[0031] Step S1: raw material pretreatment: Squeeze the sludge with a water content of 60% to 90% to remove water, and use a pulverizer to pulverize the dried waste bacteria sticks to a diameter of less than 30mm;

[0032] Step S2: Mixing treatment of raw materials: first place the sludge and waste bacteria stick powder in the solid fuel manufacturing equipment and mix them evenly, and at the same time continuously add oxidant, sulfur fixing agent, bentonite, mercury fixing agent and The adhesive continues to stir until the material is evenly stirred, and the water content is controlled to be 10%-15%;

[0033] Step S3: cold press forming: the stirred mixture enters the honeycomb forming plate under the solid fuel manufacturing equipment to form a honeycomb solid fuel.

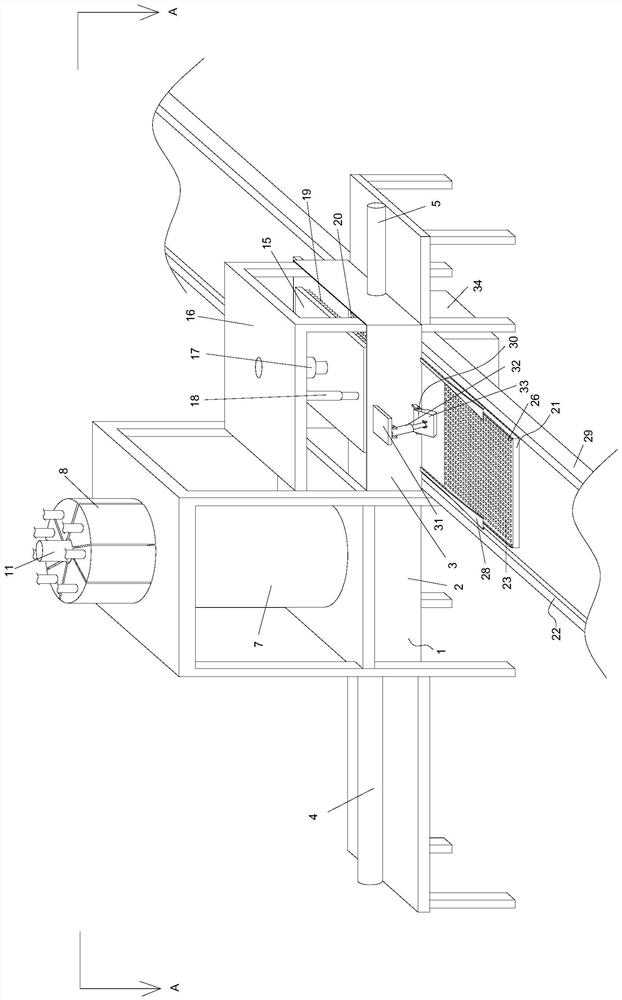

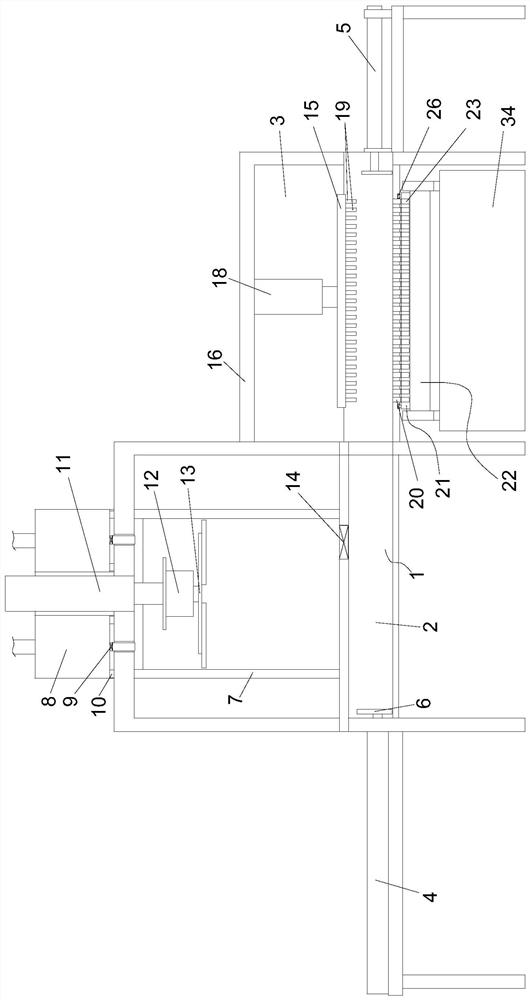

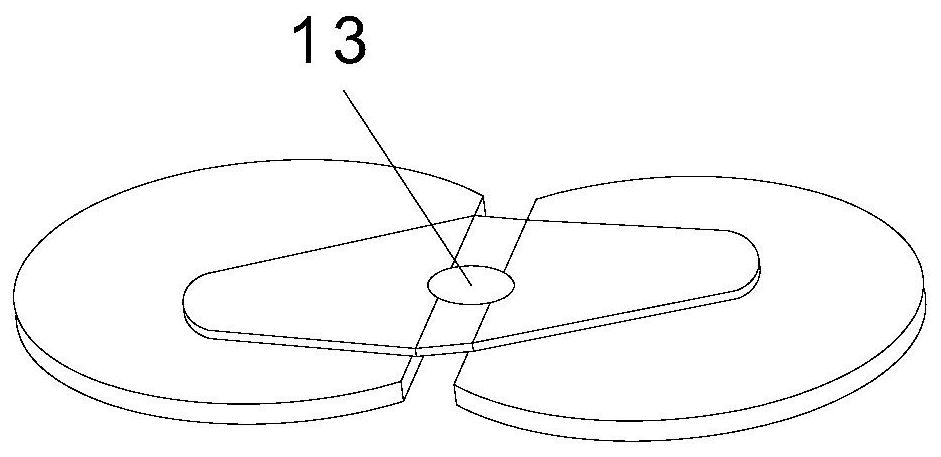

[0034] Please refer to Figure 1 to Figure 11 , the solid fuel manufacturing equipmen...

Embodiment 1

[0039] Example 1: A solid fuel derived from sludge waste bacteria sticks, which is composed of the following raw materials in mass percentage: sludge 50%, waste bacteria sticks 40%, oxidant 3.8%, sulfur-fixing agent 3%, bentonite 0.2%, mercury fixation Agent 2.8%, adhesive 0.2%.

[0040] Preparation steps: (1) Squeeze sludge with a water content of 60% to 90% to remove water, and use a pulverizer to crush the dried waste bacteria sticks to a diameter of less than 30mm; (2) Sludge and waste The bacteria stick powder is first placed in the solid fuel manufacturing equipment and mixed evenly, and at the same time, the oxidant, sulfur fixing agent, bentonite, mercury fixing agent and adhesive are continuously added to the solid fuel manufacturing equipment and continue to stir until the material is evenly stirred, and its The water content is 10%-15%; (3) The stirred mixture enters the honeycomb forming plate under the solid fuel manufacturing equipment to form a honeycomb solid f...

Embodiment 2

[0042] Embodiment 2: A solid fuel derived from sludge waste bacteria sticks, consisting of the following raw materials in mass percentage: 40% of sludge, 46% of waste bacteria sticks, 4.6% of oxidants, 4% of sulfur-fixing agents, 0.4% of bentonite, solid mercury Agent 4.7%, adhesive 0.3%.

[0043] Preparation steps: (1) Squeeze sludge with a water content of 60% to 90% to remove water, and use a pulverizer to crush the dried waste bacteria sticks to a diameter of less than 30mm; (2) Sludge and waste The bacteria stick powder is first placed in the solid fuel manufacturing equipment and mixed evenly, and at the same time, the oxidant, sulfur fixing agent, bentonite, mercury fixing agent and adhesive are continuously added to the solid fuel manufacturing equipment and continue to stir until the material is evenly stirred, and its The water content is 10%-15%; (3) The stirred mixture enters the honeycomb forming plate under the solid fuel manufacturing equipment to form a honeyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com