Energy-saving long-service-life low-ash-content diesel engine oil composition

An oil composition, long-life technology, applied in lubricating composition, petroleum industry, etc., can solve problems such as unsatisfactory engine lubrication requirements, high sulfate ash content, etc., achieve good fuel economy, extend oil change intervals, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

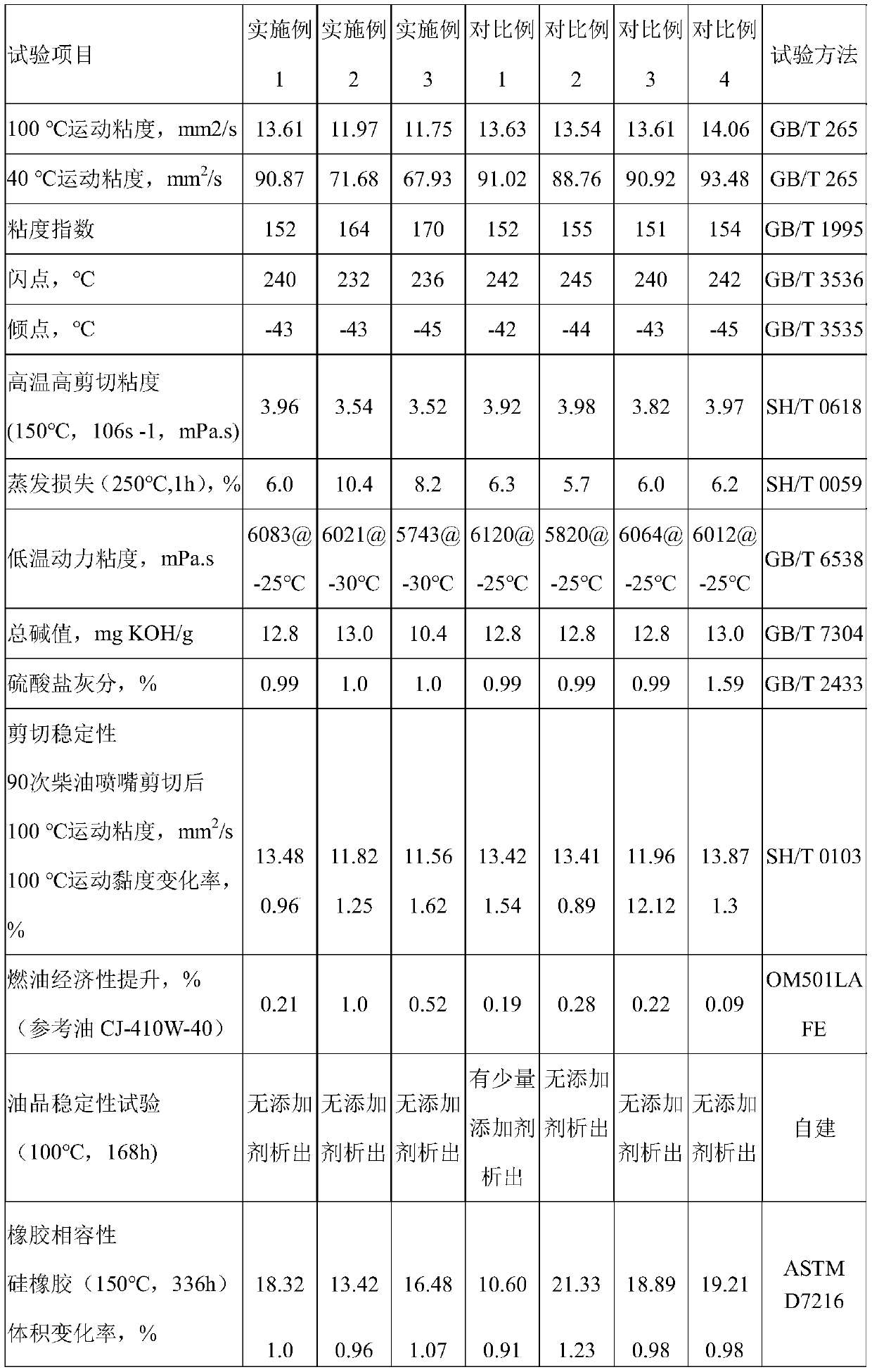

Examples

Embodiment 1

[0021] Long-life low-ash diesel engine oil 10W-40 made by blending the following components according to mass percentage:

[0022] Group III base oil 100N: 22.8%

[0023] Group III base oil 250N: 29.2%

[0024] Synthetic ester Prolube 3970: 20%

[0025] Viscosity modifier SV203: 6.0%

[0026] Diesel engine oil compound D3336: 21.4%

[0027] Thioether phenol antioxidant L115: 0.3%

[0028] Polymethylmethacrylate V1-300: 0.3%

Embodiment 2

[0030] Long-life low-ash diesel engine oil 5W-30 made by blending the following components according to mass percentage:

[0031] Group III base oil 100N: 53.7%;

[0032] Group III base oil 150N: 4%;

[0033] Synthetic ester KETJENLUBE16:8%

[0034] Viscosity modifier SV163: 12%

[0035] Engine compound D3336: 21.4%

[0036] Thioether phenolic antioxidant L115: 0.5%

[0037] Polymethylmethacrylate V1-300: 0.4%

Embodiment 3

[0039] Long-life low-ash diesel engine oil 10W-30 made by blending the following components according to mass percentage:

[0040] Group III base oil 150N: 63%;

[0041] Synthetic ester Priolube 3970: 15%

[0042] Viscosity modifier SV 201: 4.5%

[0043] Engine Compound Infineum D3504L: 17%

[0044] Thioether phenol antioxidant L118: 0.2%

[0045] Polymethylmethacrylate V1-180: 0.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com