Method for removing sodium and sulfur and enriching gold from crude antimony

A technology for enriching gold and crude antimony, applied in the field of metallurgy, can solve the problems of unsatisfactory metal antimony, complicated operation, long process, etc., and achieve the effect of good effect, simple operation process and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

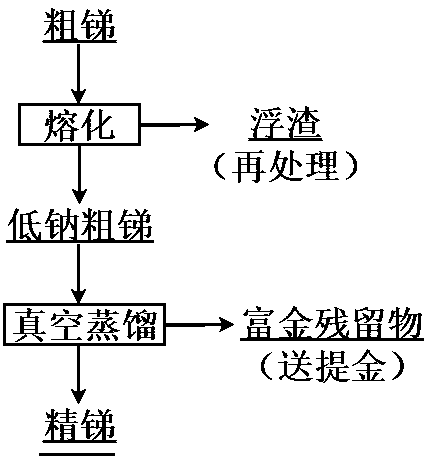

[0024] Example 1: as figure 1 As shown, the method steps of this crude antimony desalination and gold enrichment are as follows:

[0025] (1) The crude antimony (the mass percentage content of Sb is 83.78%, the Na content is 5.55%, the S content is 3.41%, the Au content is 150.05g / t, the Fe content is 0.25%, the As content is 0.067%, and the Se content is 0.25%. 0.049%) was added to the pre-melting furnace of the vacuum furnace, and the temperature was raised to 650 °C under an argon atmosphere for 60 minutes, so that the complex crystalline salt of sodium and sulfur in the crude antimony was transformed into a simple crystalline salt of sodium and sulfur, while the crude antimony was The antimony in the antimony is melted and the simple crystalline salt of sodium and sulfur is insoluble. After slag removal, the crude antimony with low sodium and sulfur is obtained (the mass percentage content of Sb is 97.12%, the content of Na is 0.17%, the content of S is 0.22%, and the cont...

Embodiment 2

[0027]Embodiment 2: the method steps of this crude antimony desalination and gold enrichment are as follows:

[0028] (1) The mass percentage content of crude antimony (Sb is 93.69%, Na content is 0.4%, S content is 1.53%, Au content is 48g / t, Fe content is 0.17%, As content is 0.044%, Se content is 0.033%) was added to the pre-melting furnace of the vacuum furnace, and the temperature was raised to 670 °C under an argon atmosphere, and then kept at a constant temperature for 120 minutes, so that the complex crystalline salt of sodium and sulfur in crude antimony was transformed into a simple crystalline salt of sodium and sulfur. The medium antimony is melted but the simple crystalline salts of sodium and sulfur are insoluble. After slag removal, the crude antimony with low sodium and sulfur is obtained (the mass percentage content of Sb is 98.53%, the content of Na is 0.09%, the content of S is 0.11%, and the content of Au is 170.27g / t);

[0029] (2) Add low-sodium crude a...

Embodiment 3

[0030] Embodiment 3: the method steps of this crude antimony desalination and gold enrichment are as follows:

[0031] (1) The crude antimony (the mass percentage content of Sb is 89.75%, the Na content is 3.2%, the S content is 2.19%, the Au content is 109.45g / t, the Fe content is 0.12%, the As content is 0.079%, and the Se content is 0.12%. 0.037%) was added to the pre-melting furnace of the vacuum furnace, and the temperature was raised to 700 °C under an argon atmosphere for 30 minutes, so that the complex crystalline salt of sodium and sulfur in the crude antimony was transformed into a simple crystalline salt of sodium and sulfur, while the crude antimony was The antimony in the antimony is melted and the simple crystalline salt of sodium and sulfur is insoluble. After slag removal, the crude antimony with low sodium and sulfur is obtained (the mass percentage content of Sb is 98.21%, the content of Na is 0.11%, the content of S is 0.13%, and the content of Au is 220.51g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com