Self-assembly super-resolution optical probe based on fiber optical tweezers

An optical fiber optical tweezers and optical probe technology, applied in the field of nanophotonics, can solve the problems of large optical path, high cost, complex structure, etc., and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

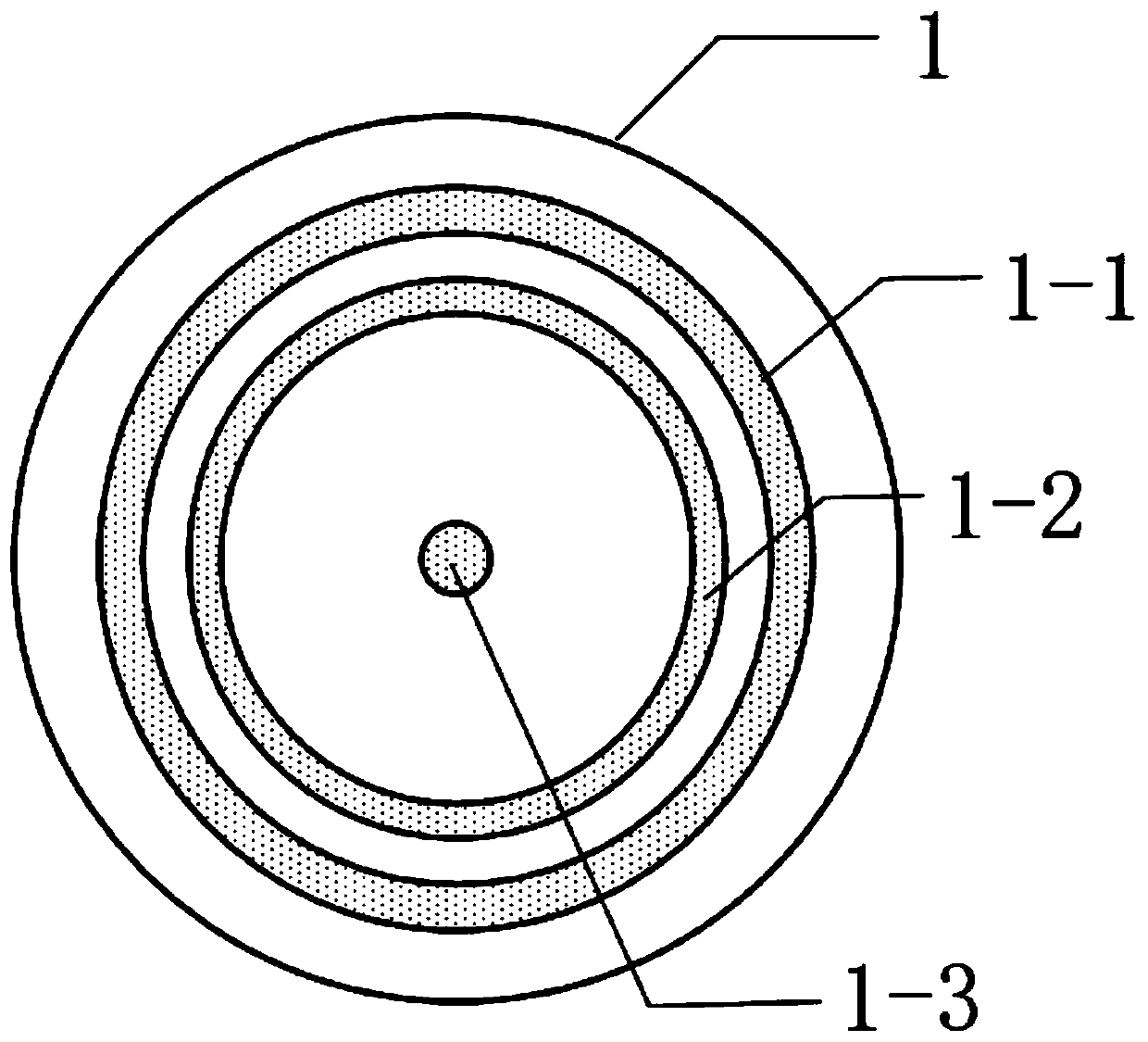

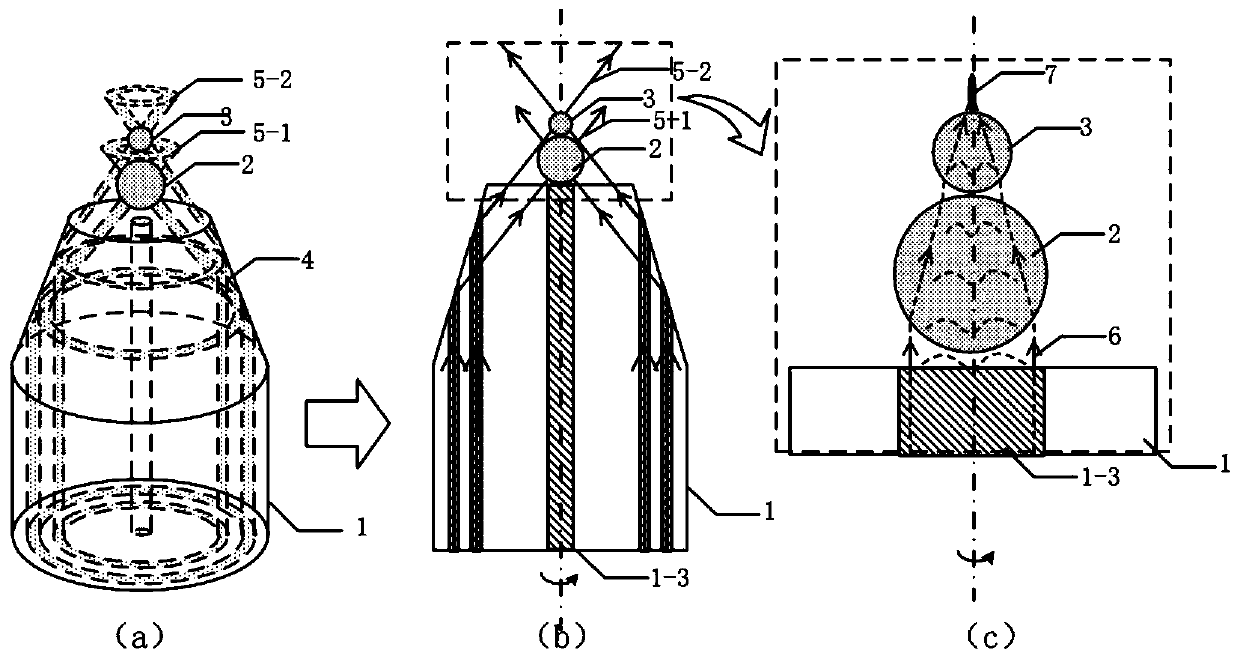

[0037] Embodiment 1: A super-resolution optical probe based on a coaxial double-ring multi-core fiber.

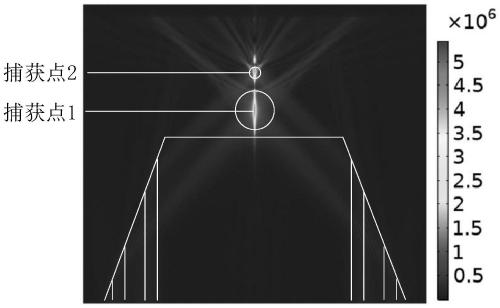

[0038] use as figure 1 The multi-core optical fiber 1 shown is taken as an example to illustrate the structure and principle of the present invention. The optical fiber has two coaxially distributed annular cores 1-1, 1-2 and an intermediate core 1-3. At the tip of the optical fiber 1, a rotationally symmetrical reflective frustum conical structure 4 is formed through precision grinding, such as figure 2 shown. The two annular fiber cores 1-1, 1-2 are used to transmit the captured light beams 5-1, 5-2 of 980nm, total reflection occurs on the slope of the truncated conical structure 4, converge outside the end face of the fiber, and converge in the axial direction of the fiber Two optical potential wells with high energy density are formed, which can stably trap two dielectric microspheres2,3. The middle fiber core 1-3 transmits a 532nm single-mode beam 6. After the bea...

Embodiment 2

[0044] Embodiment 1 presents a multi-core optical fiber with two coaxially distributed annular cores. Actually, the present invention is not limited to this kind of optical fiber. Such as Figure 9 The 5-core fiber shown 8 ( Figure 9 (a)) and 9-core fiber 9 ( Figure 9 (b)), this type of multi-core fiber also has a central core, the difference is that the other peripheral cores are located on two coaxially distributed circumferences. This type of multi-core optical fiber can also realize two stable trapping potential wells after preparing a symmetrical truncated cone at the fiber end, stably trap two dielectric microspheres, realize the compression of the middle fiber core beam, and form a super-resolution nano-optical probe.

Embodiment 3

[0046] Such as Figure 10 As shown, the intermediate core of the multi-core optical fiber adopted in the present invention can also be a two-layer waveguide structure, wherein the functions of the two outer ring cores are the same as those in the above-mentioned embodiment, and the inner layer core of the intermediate core is used for transmission. Based on the single-mode short-wavelength light generated by the nano-optical jet, the outer layer of the middle fiber core transmits a light beam with the same wavelength as the captured beam, which is used to adjust the capture position of the two microspheres, which can be adjusted by adjusting the distance between the two microspheres The spacing is used to adjust the two-stage compression effect of the two microsphere lenses on the intermediate core beam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com