3D printing distal tibial plate and preparation method therefor

A 3D printing, tibial technology, applied in the direction of outer plate, internal bone synthesis, medical science, etc., can solve the problems of personalized anatomical matching, insufficient fixation stability, etc., to reduce the risk of skin flap necrosis, high degree of anatomical matching, notch low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

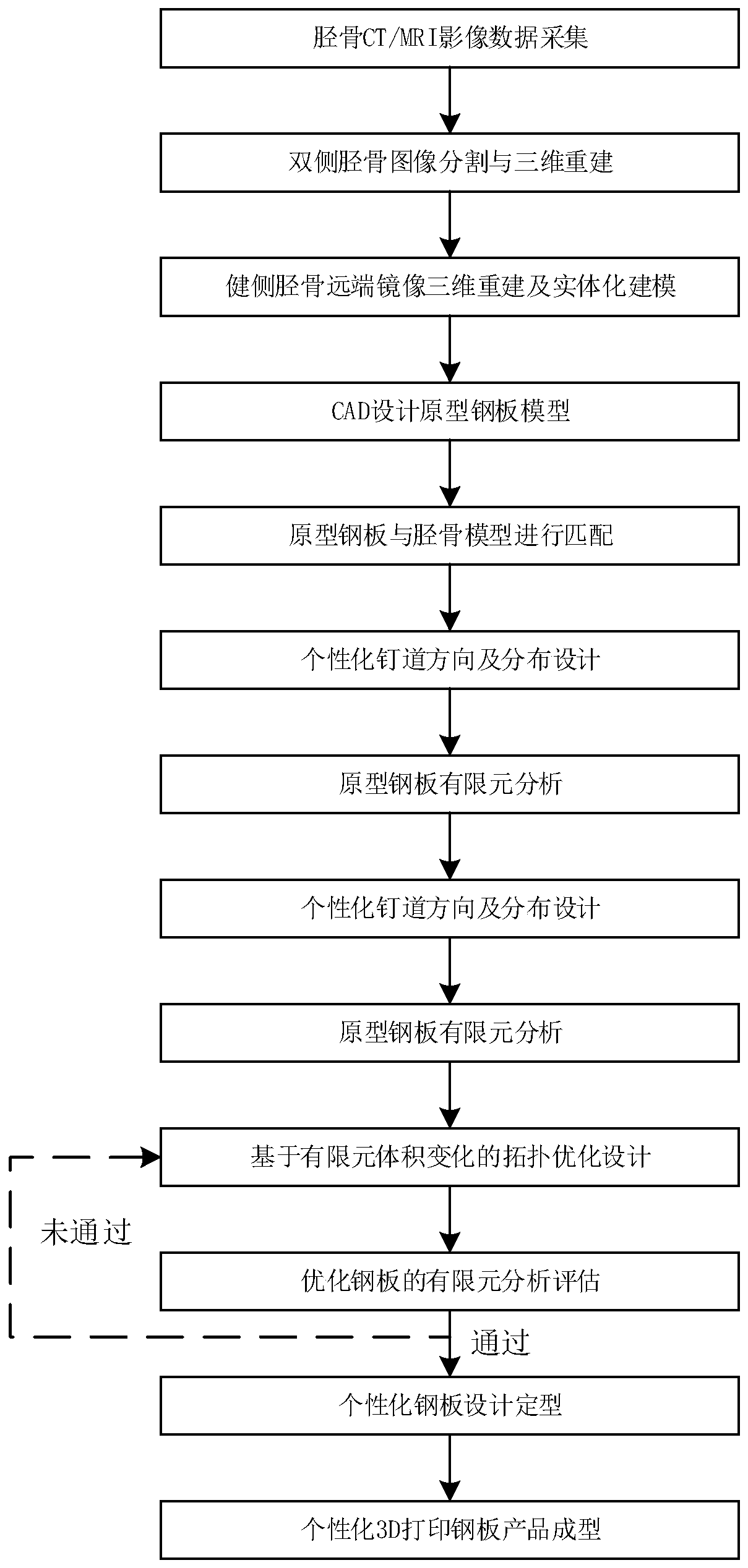

[0048] A method for preparing a 3D printed distal tibial plate, such as figure 1 As shown, the design method is realized through the following steps:

[0049] 1.1. Collect the computed tomography data of the affected side and the healthy bilateral tibia of the target object, and import the obtained computed tomography image data of the target object into the 3D reconstruction system. In the segmentation process, the initial three-dimensional model of the bilateral tibia of the target object is established, including the initial three-dimensional model of the healthy-side tibia and the initial three-dimensional model of the affected-side tibia of the target object.

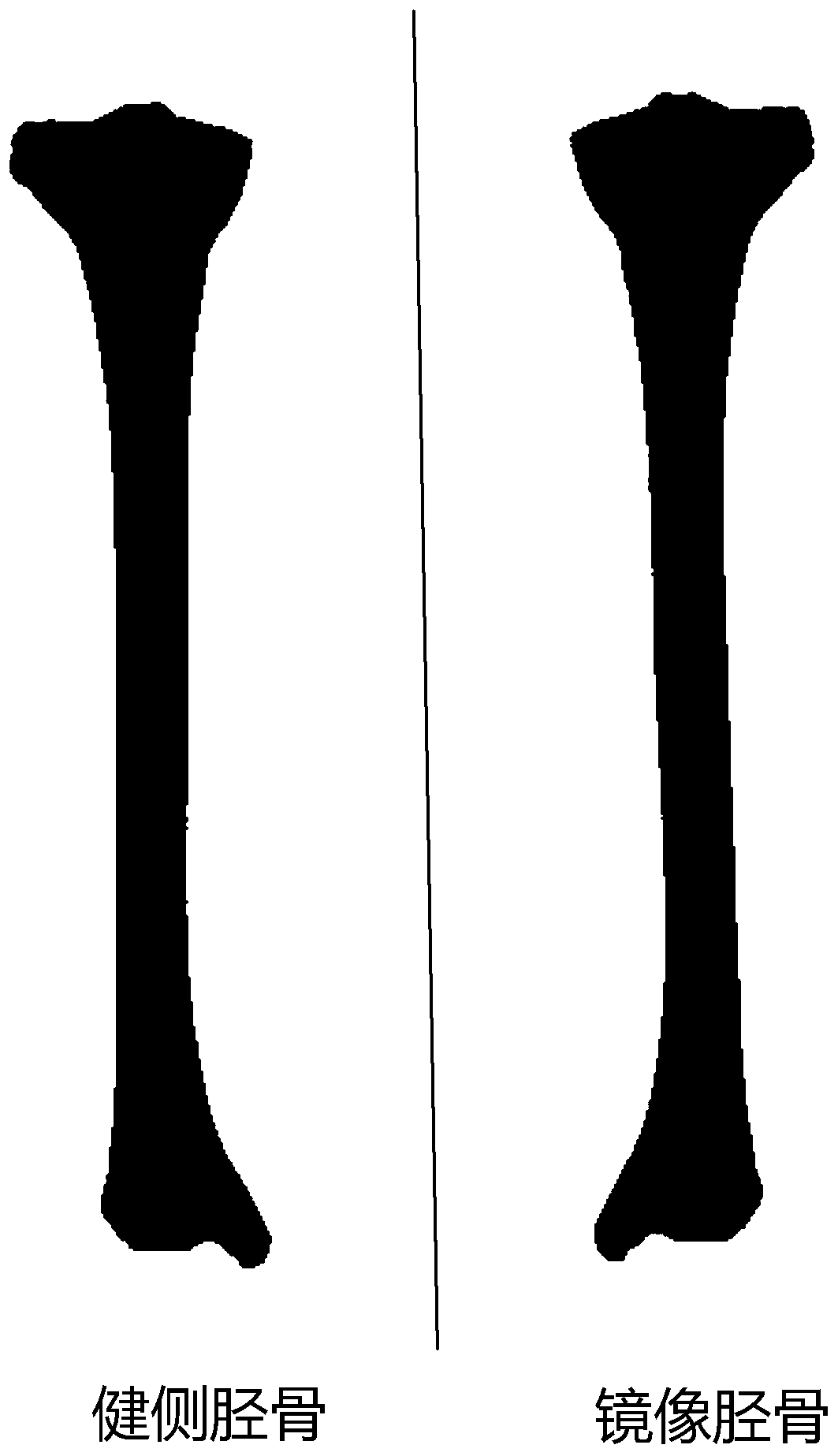

[0050] Specifically, the computed tomographic image data of the bilateral tibia of the target object is collected, and the obtained computed tomographic image data of the bilateral tibia of the target object is imported into 3D reconstruction software for image segmentation processing, and a 3D model of the bilater...

Embodiment 2

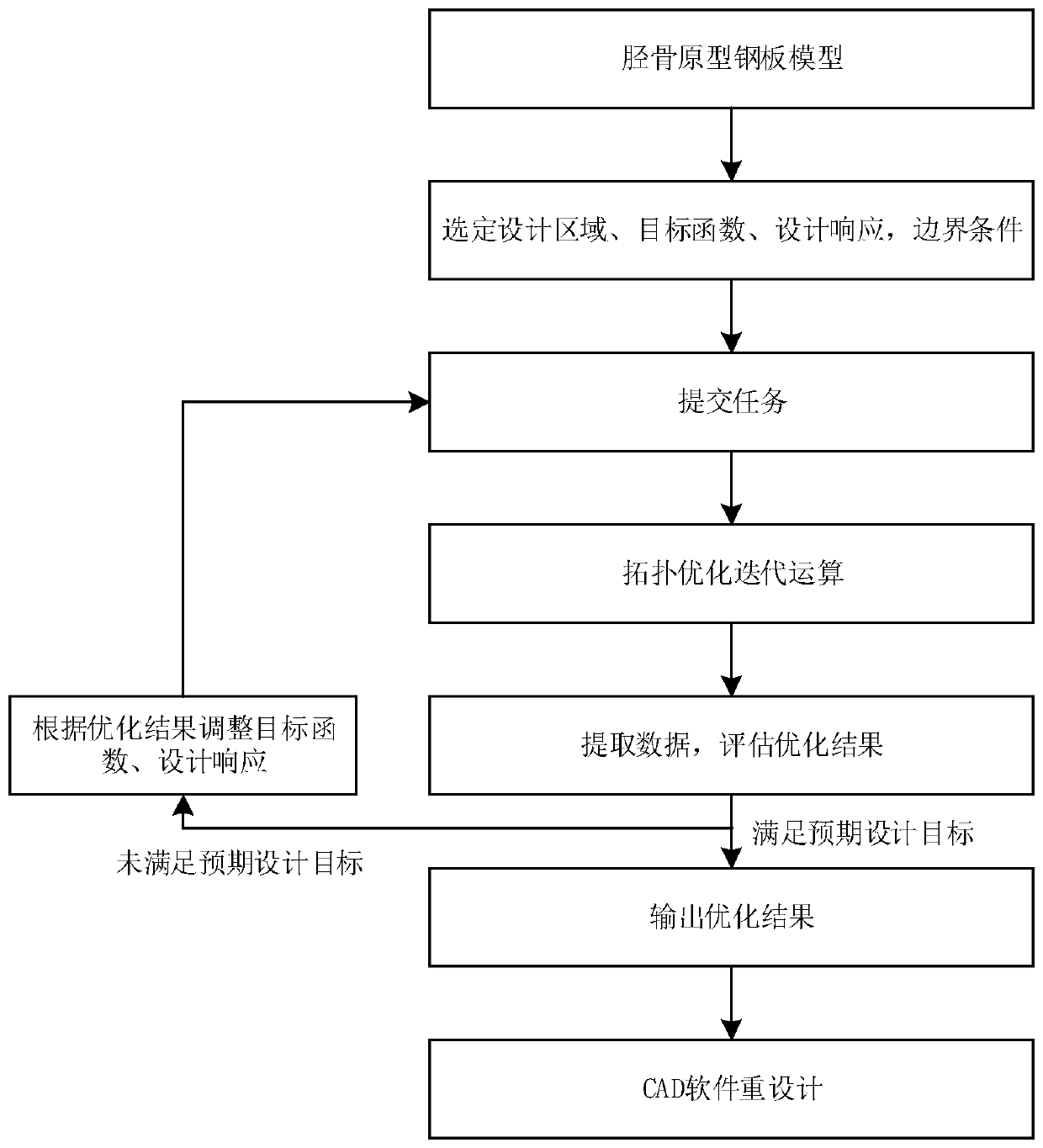

[0085] A method for preparing a 3D printed tibial plate, the other features of which are the same as those in Embodiment 1, except that the 3D printed tibial plate adopts the topology optimization technology of the finite element model.

[0086] The shape design of the steel plate with maximum volume reduction obtained by the topology optimization technology in the present invention can effectively reduce the notch of the steel plate on the premise of ensuring the maximum fixation rigidity, effectively protect the blood supply of local soft tissues and provide effective support for the collapsed articular surface , so as to avoid the related complications of autologous bone support and bone grafting, so that the tibia can fully restore its pre-injury shape.

Embodiment 3

[0088] A method for preparing a 3D printed distal tibia plate, which has the functional devices of Embodiment 1 and Embodiment 2. The difference is that the 3D printed tibial plate has a highly irregular and personalized surface,

[0089] Highly irregular and personalized curved surface, traditional machine tool processing is difficult to complete the forming and manufacturing of the steel plate through the cutting process, and the tibia steel plate designed by the present invention is directly manufactured by 3D printing forming method, realizing the direct forming of the steel plate, saving time and cost at the same time It also overcomes the shortcomings of traditional manufacturing techniques such as high cost and cumbersome procedures. At the same time, the personalized steel plate formed directly by 3D printing also avoids the decrease in mechanical strength caused by repeated shaping during the operation, and also greatly shortens the operation time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com