An injectable-porous-drug-loaded polymethyl methacrylate-based composite scaffold bone graft material and its preparation method

A polymethyl methacrylate and composite stent technology, which is used in medical science, prosthesis, etc., can solve the problems of mismatching mechanical properties with natural bone, high polymerization reaction temperature, and shedding of surrounding tissue, so as to reduce the cost of treatment. , the matching of mechanical characteristics, the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

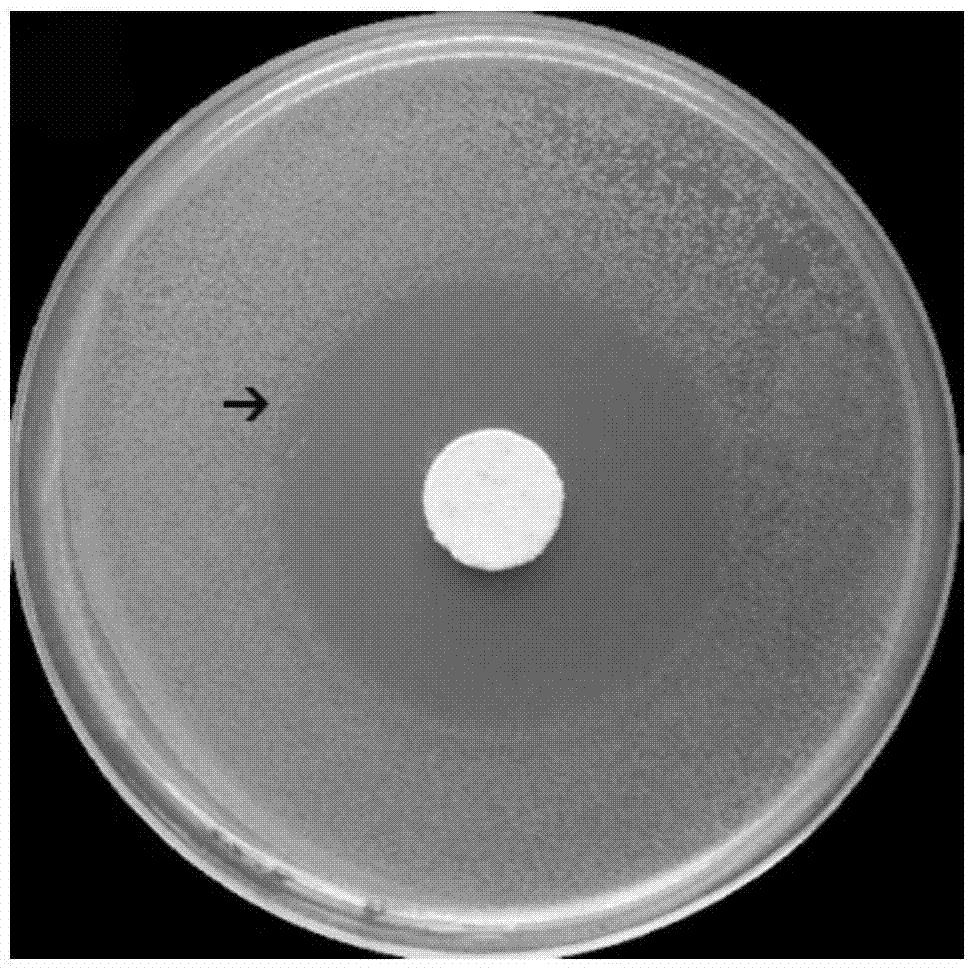

Examples

Embodiment 1

[0042] (1) Dissolve chitosan (CS) in a 0.1mol / L hydrochloric acid solution at room temperature to prepare a CS hydrochloric acid solution with a mass concentration of 2%. After the dissolution is complete, stir in an ice bath for 15 minutes.

[0043] (2) At the same time, dissolve sodium glycerophosphate (GP) in distilled water to prepare a 50% mass concentration GP solution, and place it in an ice bath for 15 minutes.

[0044] (3) Under constant stirring, slowly drop 0.5 mL of GP solution into 4.5 mL of CS hydrochloric acid solution, keep the solution free of turbidity, and stir for 20 minutes to obtain a uniformly mixed CS-GP solution.

[0045] (4) Add 25mg of gentamicin sulfate (GM) and 300mg of hydroxyapatite (HA) to the well-mixed CS-GP solution, and ultrasonic treatment to make it evenly mixed to obtain CS-GP / Nano-HA / GM mixture.

[0046] (5) Place the CS-GP / Nano-HA / GM mixed solution in a 37°C incubator, and form a CS-GP / Nano-HA / GM gel after 5 minutes.

[0047] (6) The CS-GP / Nano-...

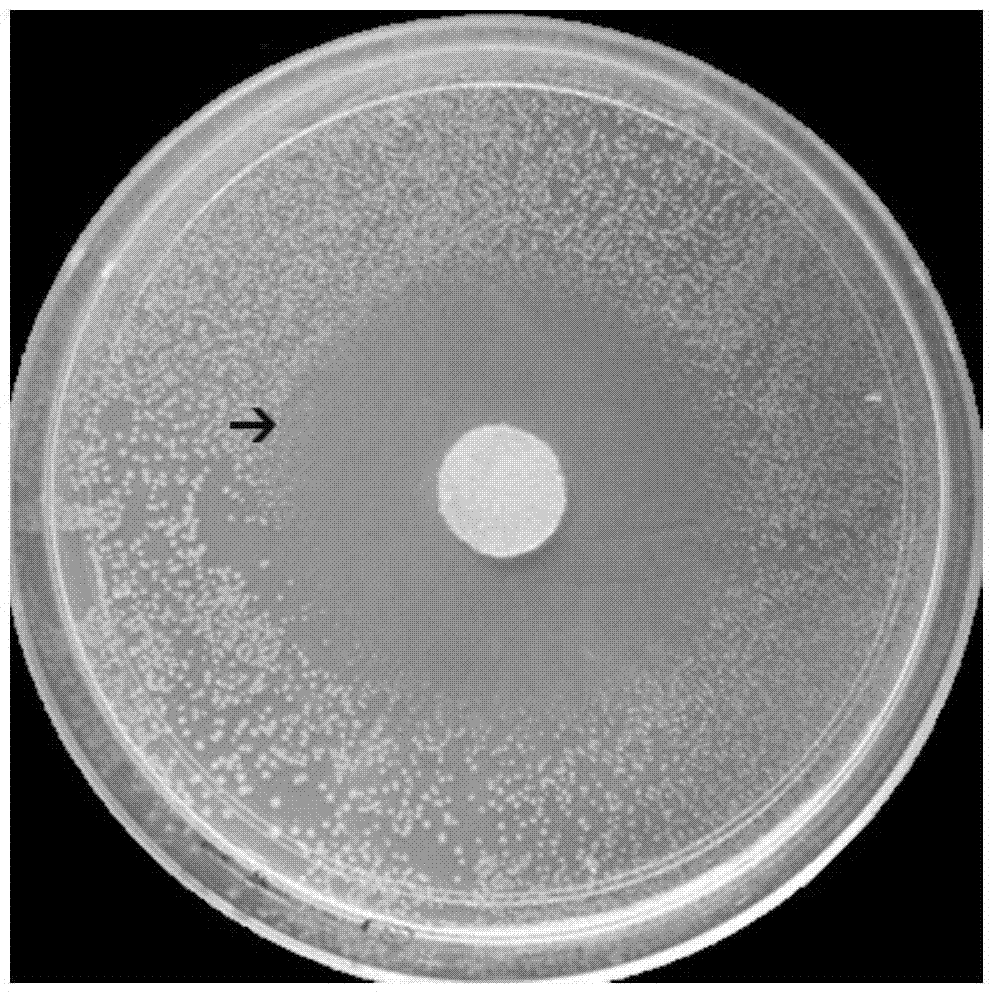

Embodiment 2

[0050] (1) Dissolve chitosan (CS) in a 0.1mol / L hydrochloric acid solution at room temperature to prepare a CS hydrochloric acid solution with a mass concentration of 2%. After the dissolution is complete, stir in an ice bath for 15 minutes.

[0051] (2) At the same time, dissolve sodium glycerophosphate (GP) in distilled water to prepare a 50% mass concentration GP solution, and place it in an ice bath for 15 minutes.

[0052] (3) Under constant stirring, slowly drop 0.5 mL of GP solution into 4.5 mL of CS hydrochloric acid solution, keep the solution free of turbidity, and stir for 20 minutes to obtain a uniformly mixed CS-GP solution.

[0053] (4) Add 25mg vancomycin (VM) and 300mg hydroxyapatite (HA) to the well-mixed CS-GP solution, and ultrasonic treatment to make it evenly mixed to obtain a CS-GP / Nano-HA / VM mixed solution .

[0054] (5) Place the CS-GP / Nano-HA / VM mixed solution in a 37°C incubator and form a gel after 5 minutes.

[0055] (6) The CS-GP / Nano-HA / VM gel is freeze-dr...

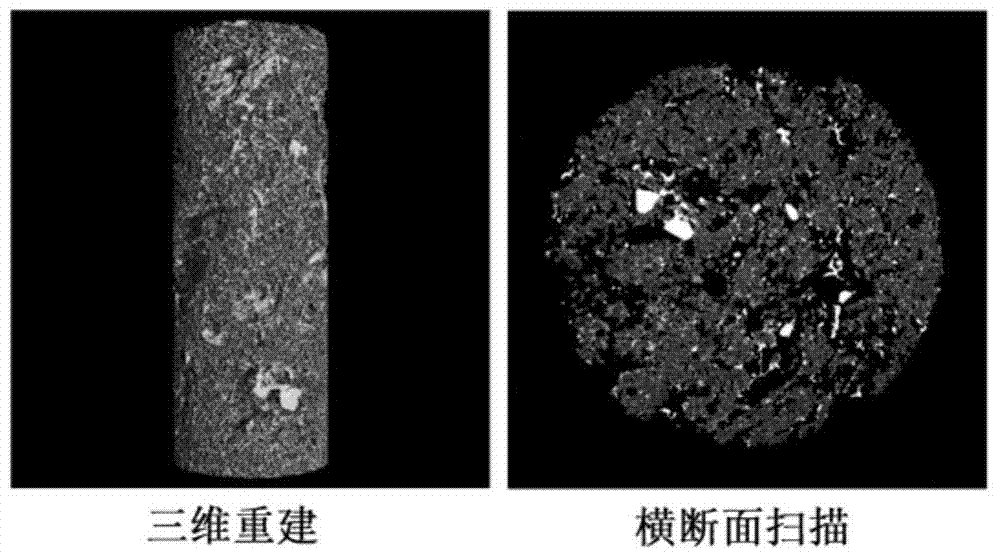

Embodiment 3

[0058] (1) Dissolve chitosan (CS) in a 0.1mol / L hydrochloric acid solution at room temperature to prepare a CS hydrochloric acid solution with a mass concentration of 2%. After the dissolution is complete, stir in an ice bath for 15 minutes.

[0059] (2) At the same time, dissolve sodium glycerophosphate (GP) in distilled water to prepare a 50% mass concentration GP solution, and place it in an ice bath for 15 minutes.

[0060] (3) Under constant stirring, slowly drop 0.5 mL of GP solution into 4.5 mL of CS hydrochloric acid solution, keep the solution free of turbidity, and stir for 20 minutes to obtain a uniformly mixed CS-GP solution.

[0061] (4) Add 25mg of gentamicin sulfate (GM) and 300mg of hydroxyapatite (HA) to the well-mixed CS-GP solution, and ultrasonic treatment to make it evenly mixed to obtain CS-GP / Nano-HA / GM mixture.

[0062] (5) Place the CS-GP / Nano-HA / GM mixed solution in a 37°C incubator, and form a CS-GP / Nano-HA / GM gel after 5 minutes.

[0063] (6) Mix the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com