Novel coating medical porous zinc material and preparation method thereof

A coating and a new type of technology, applied in the field of biomedical metal material design and preparation, can solve the problems of difficult to prepare medical porous zinc, poor pore connectivity, low porosity, etc., and achieve improved biocompatibility, high porosity, The effect of reducing the risk of necrosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Step 1, template preprocessing;

[0075] Step 11, sample preparation;

[0076] Cut the 50PPI polyurethane sponge to 50mm in length and 50mm in width to become the first sample;

[0077] Step 12, prepare chemical degreasing liquid;

[0078] The NaOH needed to prepare 1L of chemical degreasing solution is 35g, NaOH 2 CO is 25g, Na 3 PO 4 10g, OP emulsifier 0.5ml and the balance of deionized water.

[0079] The pH value of the degreasing solution is kept between 10 and 12.

[0080] Step 13, the degreasing treatment of organic solvent;

[0081] Immerse the first sample in absolute ethanol and repeatedly extrude and stir for 60 s to degrease the organic solvent, rinse it with distilled water for 5 minutes after taking it out, and obtain the second sample;

[0082] Step 14, chemical degreasing treatment;

[0083] Immerse the second sample in the chemical degreasing solution prepared in step 12, repeatedly squeeze and stir for 5 minutes to carry out chemical degreasing...

Embodiment 2

[0135] The difference between embodiment 2 and embodiment 1 is:

[0136] Step 1, template preprocessing;

[0137] The aperture of the polyurethane sponge selected in step 11 is 40PPI;

[0138] Step 4, electrodepositing zinc layer;

[0139] The temperature of the plating solution in step 42 is 30°C, and the deposition time is 1h;

[0140] Step five, sintering treatment;

[0141] The sintering time in step five is 1h.

[0142] Step six, coating loading;

[0143] Step 61, preparing a reaction solution;

[0144] The concentration of the reaction solution was 3 mmol of solute per 70 mL of solvent.

[0145] The solutes were 640 mg of magnesium nitrate hexahydrate and 160 mg of DHTA.

[0146] The solvent is 60 mL of DMF, respectively adding 4 mL of deionized water and 4 mL of absolute ethanol.

[0147] Step 62, hydrothermal reaction;

[0148] Hang the ninth sample vertically on the polytetrafluoroethylene lining of the hydrothermal kettle, add the reaction solution, put the ...

Embodiment 3

[0153] The difference between embodiment 3 and embodiment 1 is:

[0154] Step 1, template preprocessing;

[0155] The aperture of the polyurethane sponge selected in step 11 is 60PPI;

[0156] Step 4, electrodepositing zinc layer;

[0157] The temperature of the plating solution in step 42 is 40°C, and the deposition time is 1h;

[0158] Step five, sintering treatment;

[0159] The sintering heat preservation time in step five is 2h.

[0160] Step six, coating loading;

[0161] Step 61, preparing a reaction solution;

[0162] The concentration of the reaction solution was 3 mmol of solute per 70 mL of solvent.

[0163] The solutes were 638 mg of magnesium nitrate hexahydrate, 2 mg of copper nitrate hexahydrate and 160 mg of DHTA.

[0164] The solvent is 60 mL of DMF, respectively adding 4 mL of deionized water and 4 mL of absolute ethanol.

[0165] performance analysis

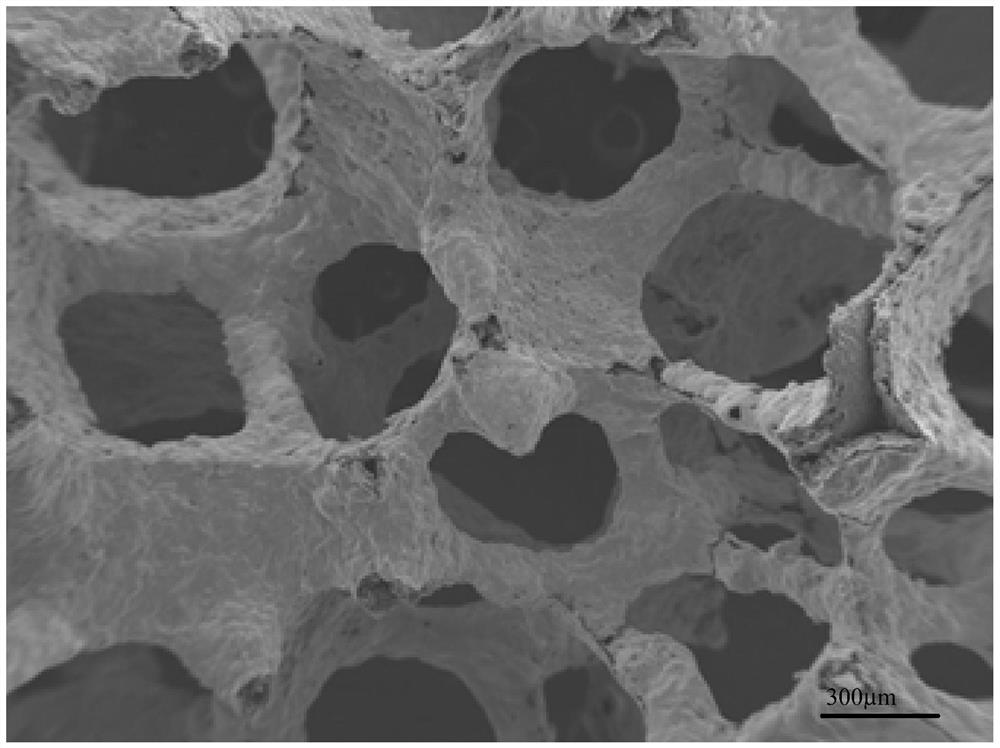

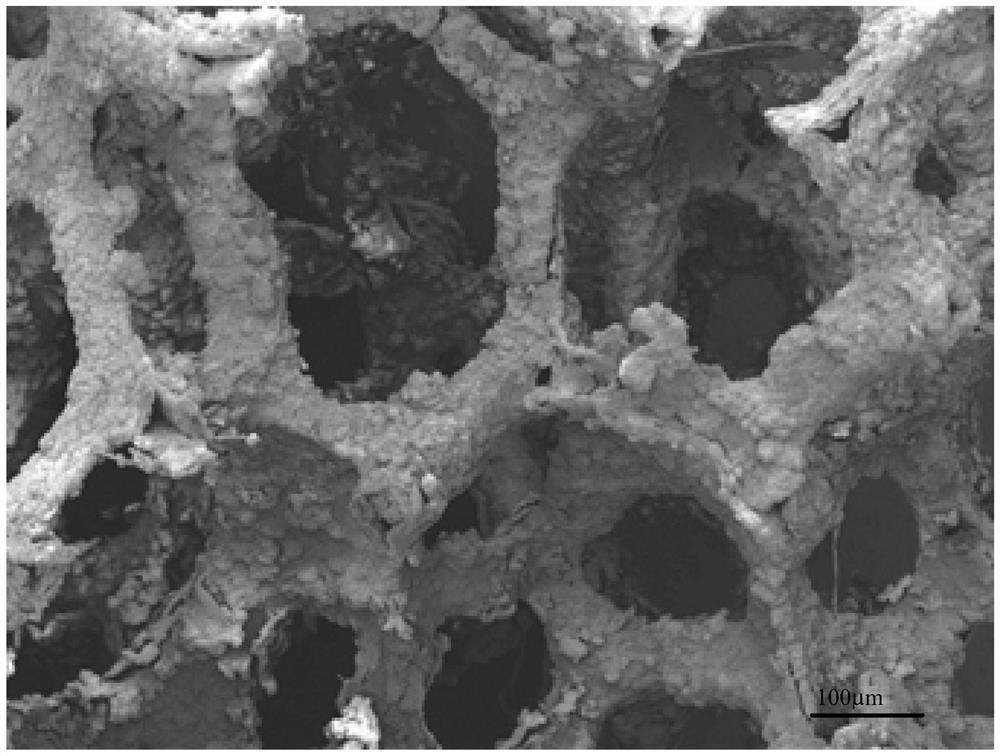

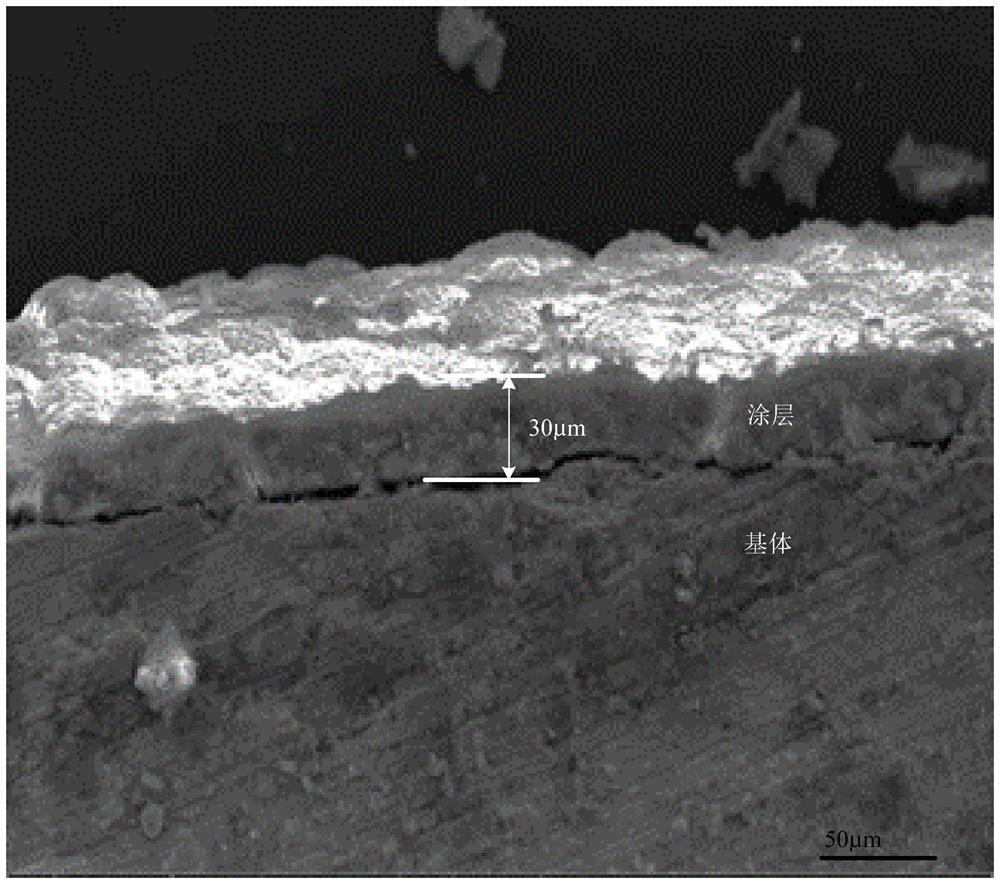

[0166] The porous zinc material obtained by the method of Example 3 has three-dimensionally connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com