A kind of cobalt lithium fluorophosphate coated with tin oxide and antimony and its surface deposition in-situ coating method and application

A technology for cobalt lithium fluorophosphate and cobalt lithium fluorophosphate preparation, which is applied in the field of in-situ coating and application of cobalt lithium fluorophosphate coated with tin antimony oxide and its surface deposition, can solve problems such as poor conductivity and cycle attenuation, and achieve Good rate characteristics, improved conductivity, and the effect of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

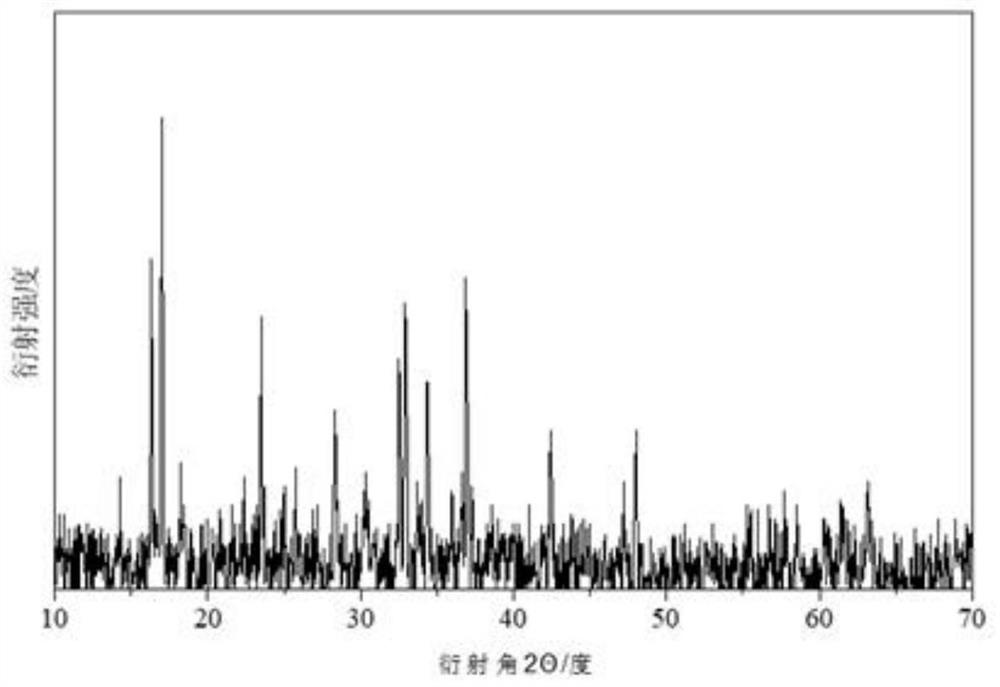

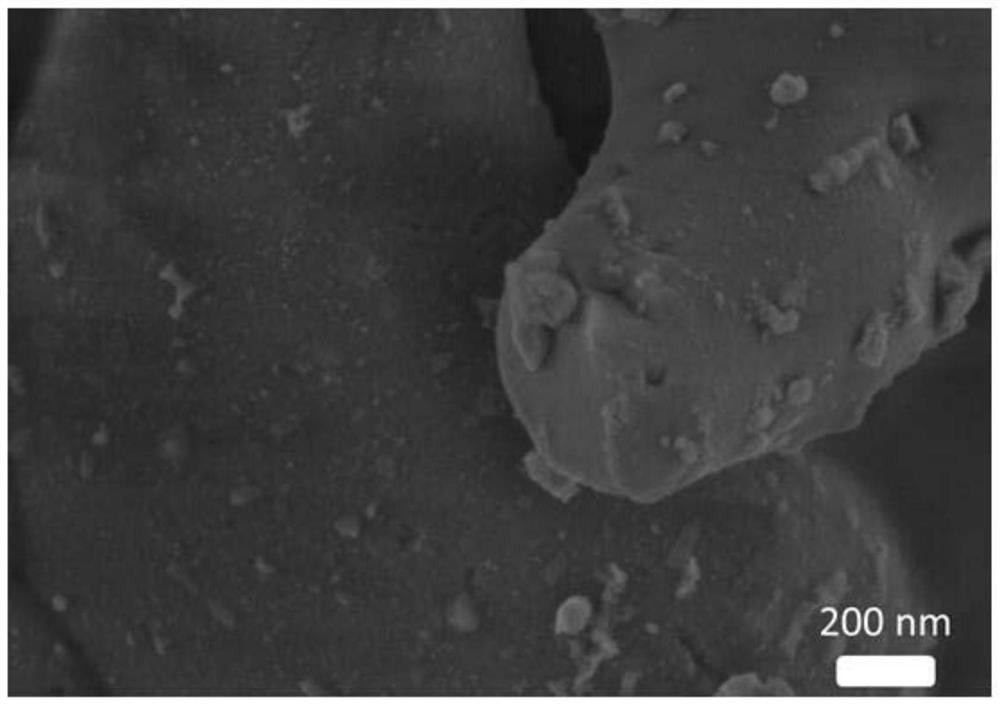

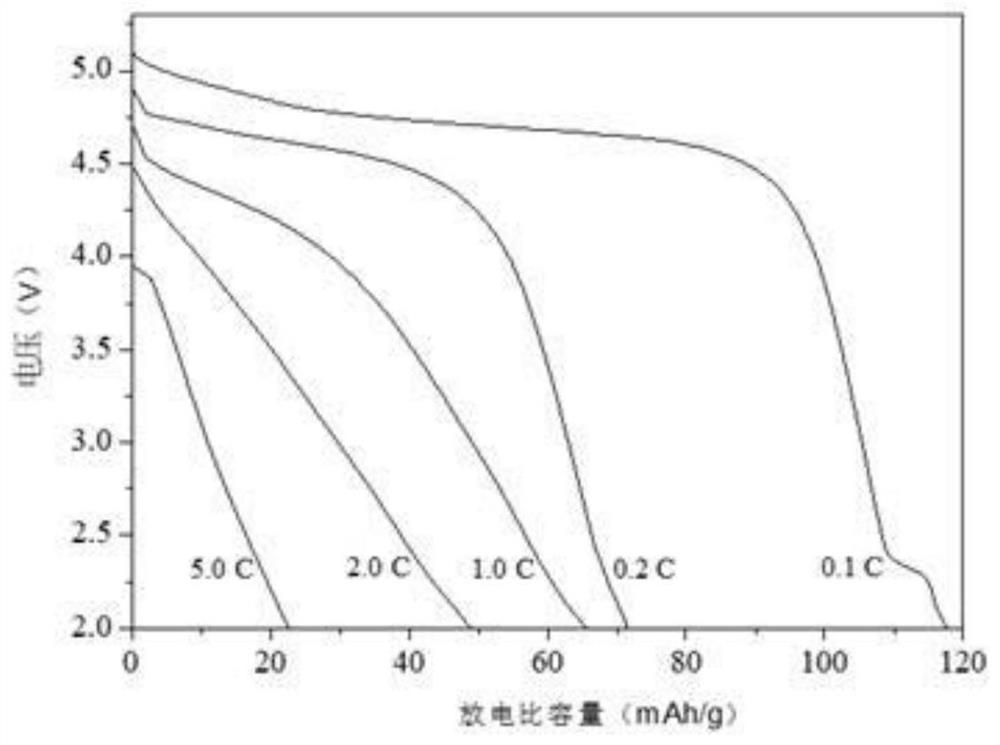

[0027] Accurately weigh 0.02mol lithium hydroxide, 0.02mol cobalt acetate, 0.02mol phosphoric acid, and 0.02mol lithium fluoride, add them to 25 mL of deionized water, stir for 4 h and mix well, and then transfer them to the reaction kettle. Heat for 11 h, cool to room temperature, move it to a beaker to dry overnight, and grind it finely to obtain the precursor of lithium cobalt fluorophosphate. Weigh 1.0 g of lithium cobalt fluorophosphate precursor into a beaker, add 20 mL of deionized water, add 0.1900 g of tin tetrachloride and 0.0137 g of antimony trichloride while stirring, and slowly drop 8 mL of 1 mol / L sodium hydroxide, aged for 90 min, centrifuged at 6000 r / min for 8 min, washed with deionized water, and dried at 70 °C. Pre-calcined at 350 °C for 7 h under nitrogen protection, and calcined at 600 °C for 7 h. That is, the lithium cobalt fluorophosphate cathode material coated with antimony tin oxide in situ is obtained; the lithium cobalt fluorophosphate cathode ma...

Embodiment 2

[0029] Accurately weigh 0.04mol of lithium acetate, 0.02mol of cobalt oxalate, 0.02mol of phosphoric acid, and 0.02mol of ammonium fluoride, add them to 15 mL of deionized water, stir for 4 h and mix well, and then transfer them to the reaction kettle. After 10 h, it was cooled to room temperature, moved to a beaker to dry overnight, and ground finely to obtain the precursor of lithium cobalt fluorophosphate. Weigh 1.0 g lithium cobalt fluorophosphate precursor into a beaker, add 25 mL of dispersant (water: ethanol: methanol = 2:2:1), add 0.1470 g tin dichloride and 0.0096 g antimony triiodide while stirring, Slowly drop 7 mL of 1 mol L at 70°C -1 Precipitant (4 mL 1 mol / L sodium hydroxide + 3 mL concentrated ammonia water), aged for 80 min, centrifuged at 6500 r / min for 6 min, washed with deionized water, and dried at 80 °C. Pre-calcined at 300 °C for 6 h under argon protection and calcined at 680 °C for 4 h. That is, the lithium cobalt fluorophosphate cathode material coat...

Embodiment 3

[0031] Accurately weigh 0.02mol lithium hydroxide, 0.02mol cobalt nitrate, 0.02mol diammonium hydrogen phosphate, 0.02mol lithium fluoride, add them to 25 mL of deionized water, stir for 3 h and mix well, then transfer them to the reaction kettle, It was heated with water at 200 °C for 11 h, cooled to room temperature, moved to a beaker to dry overnight, and finely ground to obtain the precursor of lithium cobalt fluorophosphate. Weigh 1.0 g of lithium cobalt fluorophosphate precursor into a beaker, add 10 mL of ethanol, add 0.2130 g of tin sulfate and 0.0097 g of antimony tribromide while stirring, and slowly drop 12 mL of 1 mol / L lithium hydroxide at 70 °C , aged for 30 min, centrifuged at 5000 r / min for 10 min, washed with deionized water, and dried at 60 °C. Under the protection of mixed gas (argon: hydrogen = 8:2), pre-calcination at 300 °C for 7 h and 550 °C for 8 h. That is, an in-situ lithium cobalt fluorophosphate positive electrode material coated with tin and antim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com