Preparation method and applications of zero-dimensional lead-free perovskite Cs3Cu2X5

A dimensional lead-free perovskite, organic solvent technology, applied in chemical instruments and methods, electrical components, nanotechnology, etc., can solve the problems of inert environment, high-purity raw materials, time-consuming and other problems, achieve low-cost, wide-ranging Effect of luminescence spectrum, short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.77943g of CsI powder and 0.3809g of CuI powder into a ball milling jar, add 2mL of absolute ethanol and 1g of ball milling beads, set the rotation speed at 1000r / min, perform ball milling at room temperature for 3h, and then separate the solid and liquid by centrifugation , and the collected solid was dried at 70 °C for 1 h to obtain the gray zero-dimensional lead-free perovskite Cs 3 Cu 2 I 5 Powder.

[0028] The prepared Cs 3 Cu 2 I 5 The powder exhibits blue fluorescence under the irradiation of 254nm ultraviolet light.

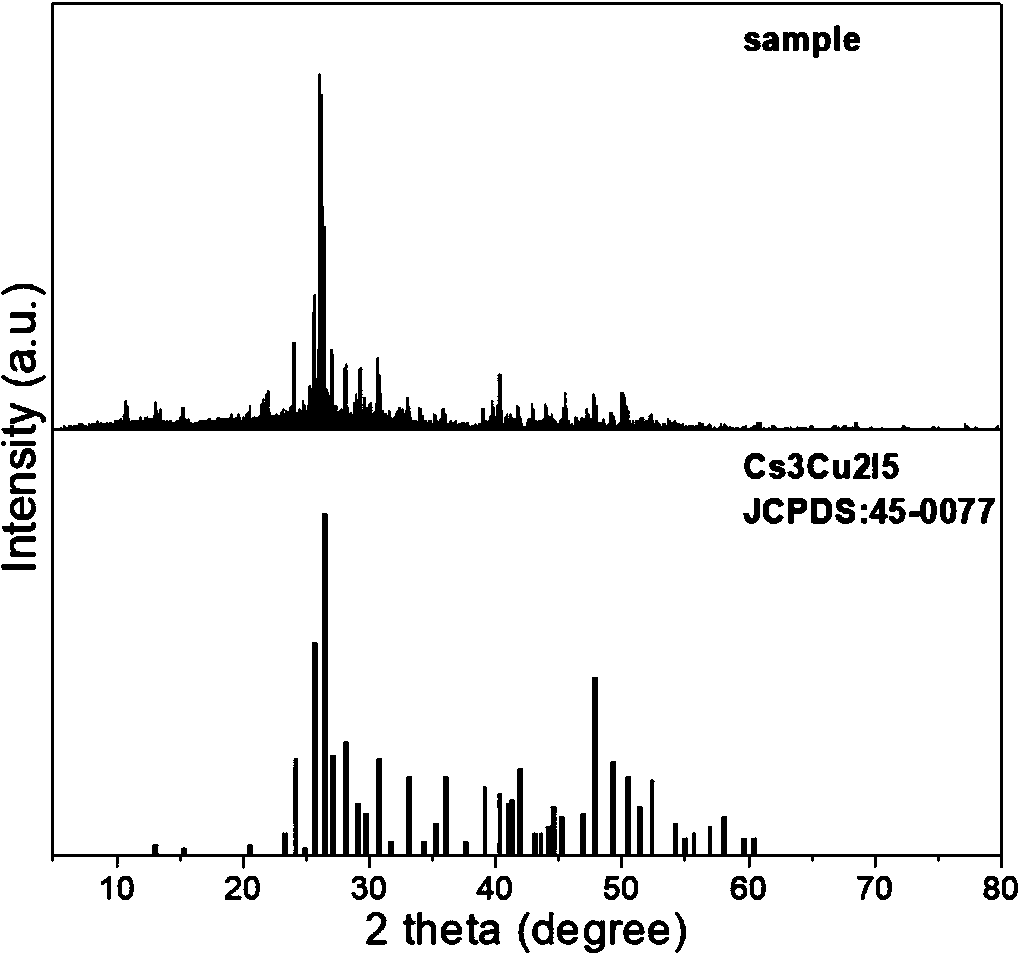

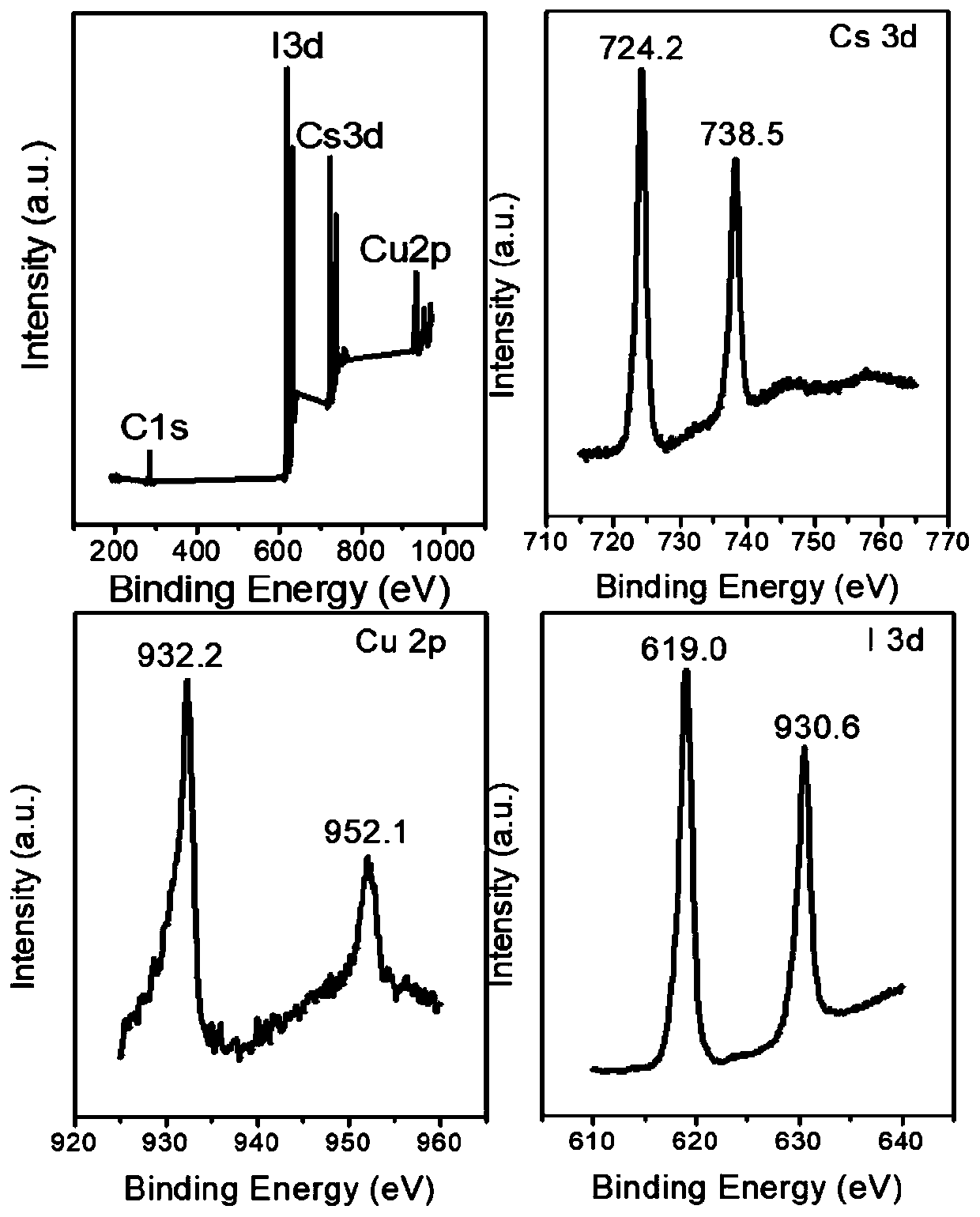

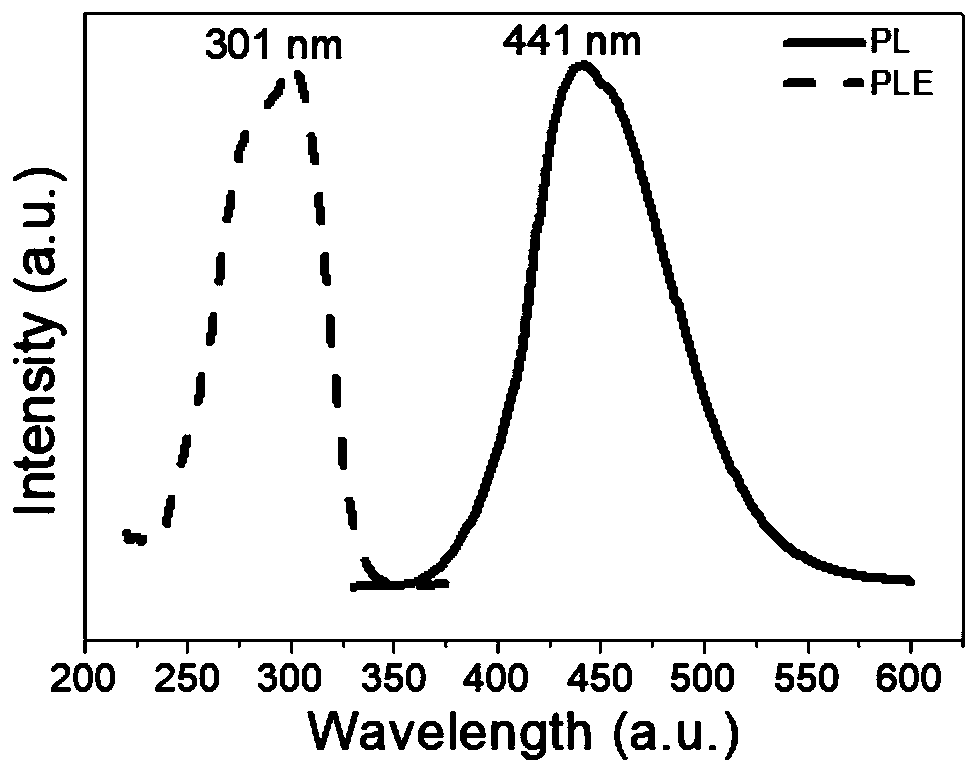

[0029] Such as figure 1 As shown, the prepared Cs 3 Cu 2 I 5 The powder appears characteristic peaks at 13.1°, 15.1°, 23.9°, 25.6°, 26.3°, 28.2°, 30.6° and 47.9°, whose positions and intensities correspond to Cs 3 Cu 2 I 5 (111), (002), (122), (312), (222), (131), (313) and (152) crystal planes of standard card JCPDS:45-0077, exhibiting positive Intersecting crystal structure, it can be preliminarily concluded that the sample is C...

Embodiment 2

[0035] Weigh 0.77943g of CsI powder and 0.3809g of CuI powder into a ball milling tank, add 2mL of absolute ethanol and 3g of ball milling beads, set the rotation speed at 1000r / min, perform ball milling at room temperature for 0.5h, and use centrifugation for solid-liquid After separation, the collected solid was dried at 80 °C for 3 h to obtain the gray zero-dimensional lead-free perovskite Cs 3 Cu 2 I 5 Powder.

[0036] The prepared Cs 3 Cu 2 I 5 The powder exhibits blue fluorescence under the irradiation of 254nm ultraviolet light.

[0037] The prepared Cs 3 Cu 2 I 5 The XRD spectrum and the XPS spectrum of the powder are identical to those shown in Example 1, so it is determined that the prepared sample is Cs 3 Cu 2 I 5 .

[0038] As determined by scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS), the prepared Cs 3 Cu 2 I 5 The contents of Cs, Cu and I in the powder are: 26.2wt%, 25.7wt%, 47.1wt%.

[0039] Using the Hamamatsu Absolute F...

Embodiment 3

[0042] Weigh 0.5050g of CsCl powder and 0.1980g of CuCl powder into a ball milling tank, add 2mL of absolute ethanol and 2g of ball milling beads, set the rotation speed at 1000r / min, perform ball milling at room temperature for 0.5h, and then use centrifugation to perform solid-liquid After separation, the collected solid was dried at 70 °C for 3 h to obtain the zero-dimensional lead-free perovskite Cs 3 Cu 2 Cl 5 Powder.

[0043] The prepared Cs 3 Cu 2 Cl 5 The powder showed green fluorescence under the irradiation of 254nm ultraviolet lamp.

[0044] Such as Figure 5 As shown, the prepared Cs 3 Cu 2 Cl 5 There are characteristic peaks at 23.2°, 29°, 30.8°, 35.3°, 37.4° and 47.5° in the powder, and their positions and intensities correspond to Cs 3 Cu 2 Cl 5 Standard card JCPDS: 24-0247, it can be preliminarily determined that the sample is Cs 3 Cu 2 Cl 5 .

[0045] Such as Figure 6 As shown, the prepared Cs 3 Cu 2 Cl 5 In the XPS spectrum of the powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminescence spectroscopy | aaaaa | aaaaa |

| luminescence spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com