Environment-friendly and low-cost regenerated aluminum alloy preparation method and device

A low-cost, aluminum alloy technology, applied in the field of aluminum alloy production, can solve irreparable problems, achieve the effects of reducing output, reducing water temperature, and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

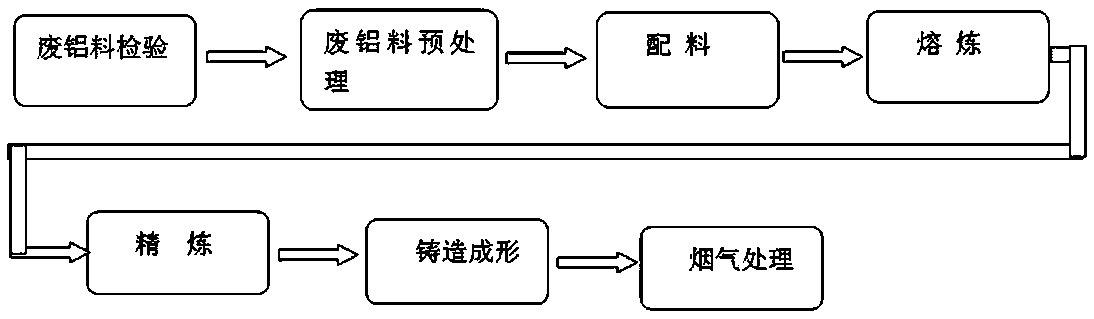

[0037] A green and low-cost secondary aluminum alloy preparation method and equipment thereof, specifically prepared through the following steps:

[0038] Step 1. Aluminum scrap inspection: sampling, sample preparation, melting, forming, sample processing, testing;

[0039] Step 2. Pretreatment of waste aluminum: crushing and sorting;

[0040] Step three, ingredients;

[0041] Step 4, smelting: charging and charging furnace, melting, slag removal;

[0042] Step 5, refining: component detection, component adjustment; degassing;

[0043] Step 6. Casting and forming: aluminum liquid transfer, aluminum liquid filtration, injection molding

[0044] Step 7. Flue gas treatment: bag dust collection, denitrification.

[0045] The specific operation of the first step is: after sampling the waste aluminum material, melt it in a crucible, cast it into a sample block for spectral detection, process it into a sample block with a lathe, and detect the chemical composition with a spectrom...

Embodiment 2

[0053] The six-burner double-chamber furnace in the present invention is divided into two chambers, a total of six burners, so that the capacity of the furnace is increased from 30 tons to 60 tons, and the aluminum liquid will not completely drain when the aluminum liquid is exported, which can ensure that the aluminum liquid The stability of the flow rate, after 30 tons of molten aluminum flows out, the remaining 30 tons of molten aluminum is thrown into the melting furnace; when feeding continues into the melting furnace, the solid aluminum material will sink into the molten aluminum after entering the melting furnace, and contact with high-temperature gas The time is very short, which effectively prevents the burning of aluminum materials and reduces solid emissions.

[0054] The whole set of furnace has six burners, which perform combustion and heat absorption operations in turn. During the whole operation process, at least one heating device performs fire-spraying heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com