Method for preparing amorphous composite coating through laser cladding

A technology of laser cladding and composite coating, which is applied in coating, metal material coating technology, etc., can solve the problem of unclear coexistence form and formation mechanism of amorphous phase and crystal phase, unsatisfactory comprehensive performance of coating, and amorphous Coating composition design and control, unstable process parameters and other problems, to achieve the effect of good macroscopic appearance, tight bonding and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

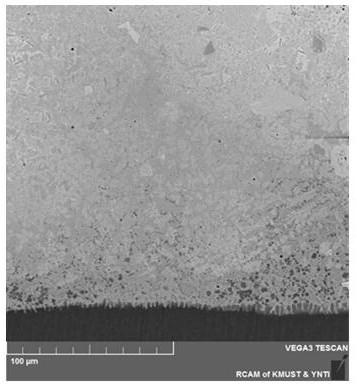

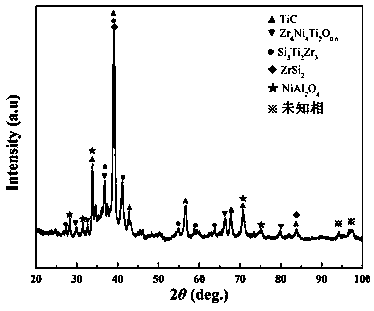

[0020] A method for preparing an amorphous composite coating by laser cladding, specifically comprising the following steps:

[0021] (1) Grind the TC4 titanium alloy with metallographic sandpaper to remove the surface oxide film, soak the polished TC4 titanium alloy in 4% NaOH aqueous solution for 10 minutes, then rinse with water and put in absolute ethanol Ultrasonic cleaning in medium to remove residual oil and impurities on the surface; after cleaning, dry at 60°C for 1 hour.

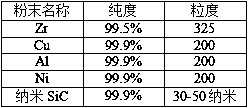

[0022] (2) Using Zr powder, Cu powder, Al powder, Ni powder, and nano-SiC powder with a purity of 99.95% as raw materials, the atomic ratio of Zr powder, Cu powder, Al powder, and Ni powder is 55:35:10: 5. Mix, and then mix the uniformly mixed powder and nano-SiC powder according to the ratio of 99.3:0.7 in mass percentage, and mix Zr powder, Cu powder, Al powder, Ni powder and nano-SiC powder uniformly by ball milling to obtain a molten Coating powder, ball milling parameters are ball milling spe...

Embodiment 2

[0026] A method for preparing an amorphous composite coating by laser cladding, specifically comprising the following steps:

[0027] (1) Grind the TC4 titanium alloy with metallographic sandpaper to remove the surface oxide film, soak the polished TC4 titanium alloy in 5% NaOH aqueous solution for 8 minutes, then rinse with water and put in absolute ethanol Ultrasonic cleaning in medium to remove residual oil and impurities on the surface; after cleaning, dry at 80°C for 0.8h.

[0028] (2) Using Zr powder, Cu powder, Al powder, Ni powder, and nano-SiC powder with a purity of 99.95% as raw materials, the atomic ratio of Zr powder, Cu powder, Al powder, and Ni powder is 55:35:10: 5. Mix, and then mix the uniformly mixed powder and nano-SiC powder according to the ratio of 99:1 by mass percentage, and mix Zr powder, Cu powder, Al powder, Ni powder and nano-SiC powder uniformly by ball milling to obtain a molten Coating powder, ball milling parameters are ball milling speed 50r / ...

Embodiment 3

[0031] A method for preparing an amorphous composite coating by laser cladding, specifically comprising the following steps:

[0032] (1) Grind the TC4 titanium alloy with metallographic sandpaper to remove the surface oxide film, soak the polished TC4 titanium alloy in 6% NaOH aqueous solution for 5 minutes, then rinse with water and put in absolute ethanol Ultrasonic cleaning in medium to remove residual oil and impurities on the surface; after cleaning, dry at 70°C for 1 hour.

[0033](2) Using Zr powder, Cu powder, Al powder, Ni powder, and nano-SiC powder with a purity of 99.95% as raw materials, the atomic ratio of Zr powder, Cu powder, Al powder, and Ni powder is 55:35:10: 5. Mix, and then mix the uniformly mixed powder and nano-SiC powder according to the ratio of 99.5:0.5 in mass percentage, and mix Zr powder, Cu powder, Al powder, Ni powder and nano-SiC powder uniformly by ball milling to obtain a molten Coating powder, ball milling parameters are ball milling speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com