Heating method special for coalbed methane thermal recovery

A heating method and coalbed methane technology, applied in the direction of separation methods, chemical instruments and methods, mining fluids, etc., can solve the problems of application effect limitations and achieve the effect of easy turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

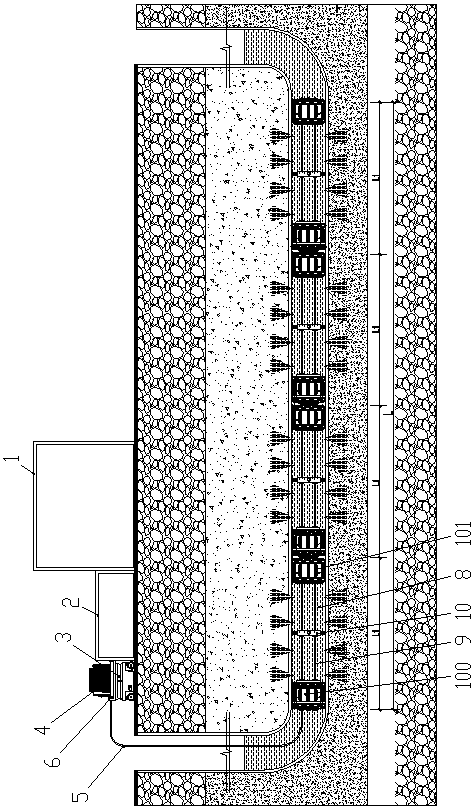

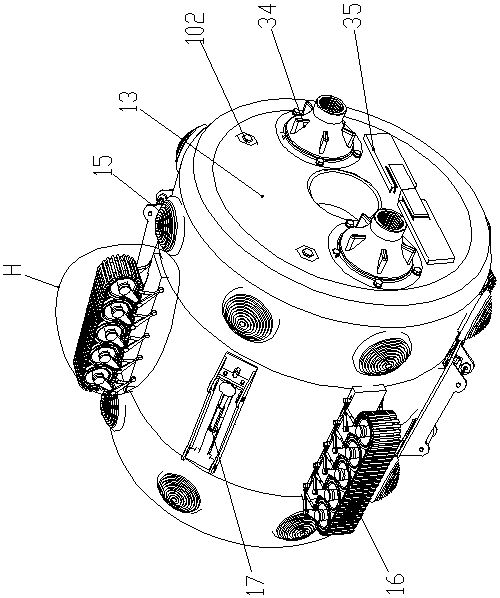

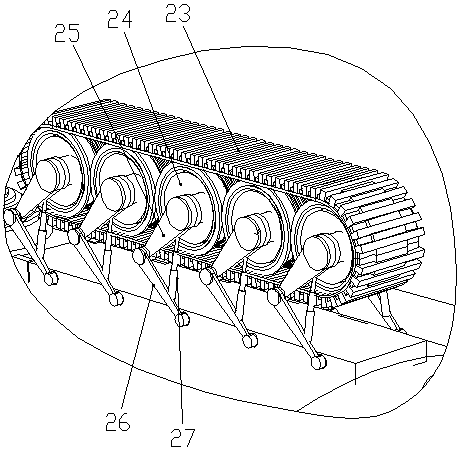

[0053] Such as Figure 1-9 As shown, the special heating method for thermal recovery of coalbed methane of the present invention comprises the following steps:

[0054] Step 1. The length of the coal seam to be thermally mined is L, and the ground control center 1, the generator 2 and the ground coiler 3 are placed on the ground above the coal seam, wherein the ground coiler 3 is equipped with an intelligent cable winch 4, and the intelligent The cable winch 4 is wound with a high temperature resistant tensile cable 5, and the outlet end of the intelligent cable winch 4 is provided with a first tension sensor 6; n groups of hollow pipeline robot groups are assembled, and one end of the high temperature resistant tensile cable 5 is connected to the generator 2 The other end of the high-temperature-resistant tensile cable 5 is connected with the last hollow pipeline robot group; the intelligent cable winch 4, the first tension sensor 6, the generator 2 and all the hollow pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com