Thermal power generating unit fused salt step energy storage and discharge peak regulating system and method

A technology of thermal power units and molten salt, which is applied to mechanical equipment, steam engine devices, machines/engines, etc., and can solve problems such as large energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

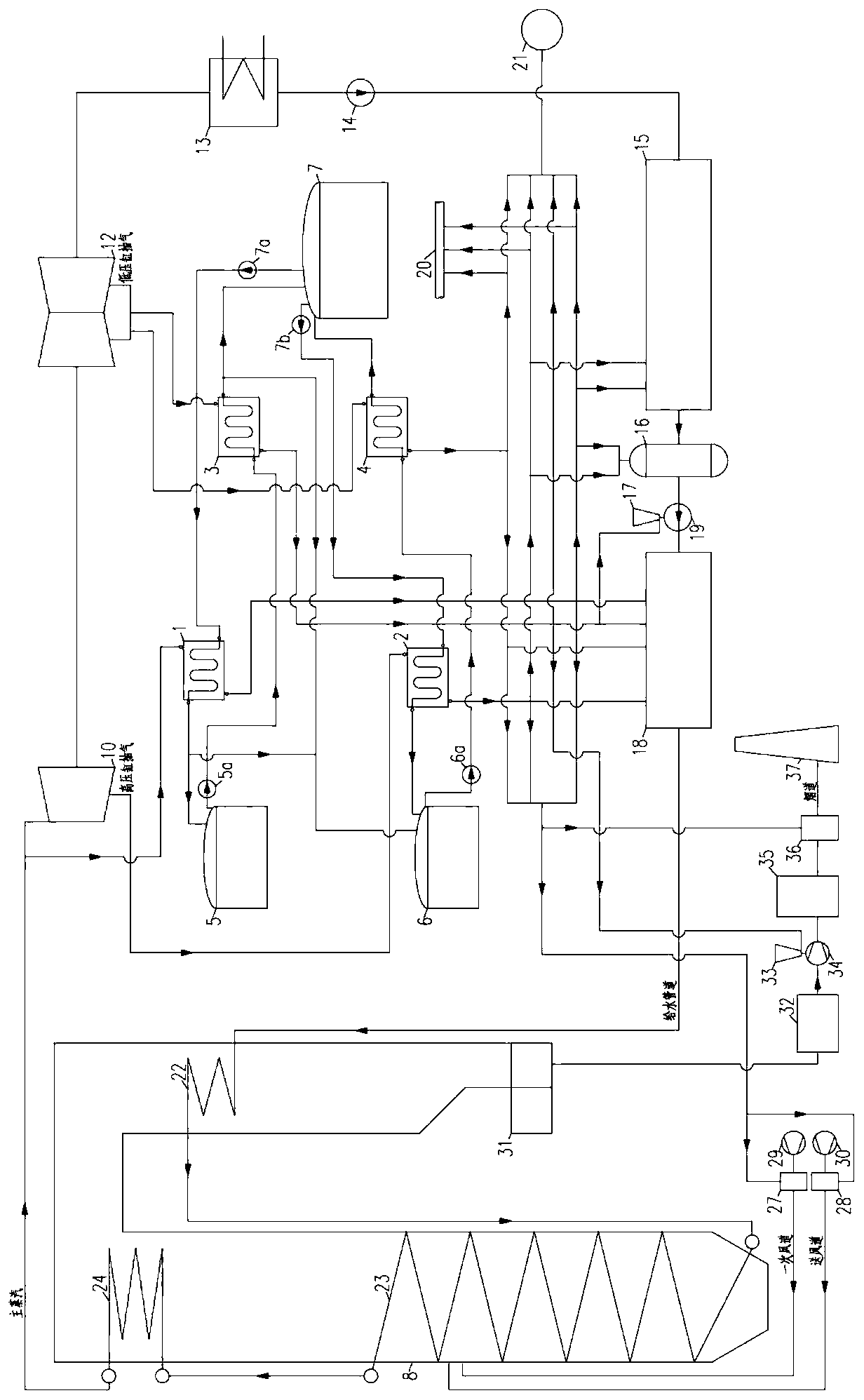

[0045] The thermal power unit in this embodiment is a non-reheating unit.

[0046] Such as figure 1 As shown, a thermal power unit molten salt cascade energy storage and discharge system includes a thermal power unit and a molten salt cascade energy storage system.

[0047] Among them, the thermal power unit includes boiler 8, main steam turbine, condenser 13, condensate pump 14, feed water pump 19, heat recovery system, feed water pump small steam turbine 17, auxiliary steam pipeline 20, induced draft fan small steam turbine 33 and flue gas system, boiler 8 Connect the main steam turbine through the steam pipeline, output the main steam to the main steam turbine, and heat the low-temperature reheated steam from the main steam turbine to the high-temperature reheated steam and send it back to the main steam turbine; The thermal system is recycled; the boiler 8 is connected to the heat recovery system through the water supply pipe, and the boiler 8 is connected to the flue gas...

Embodiment 2

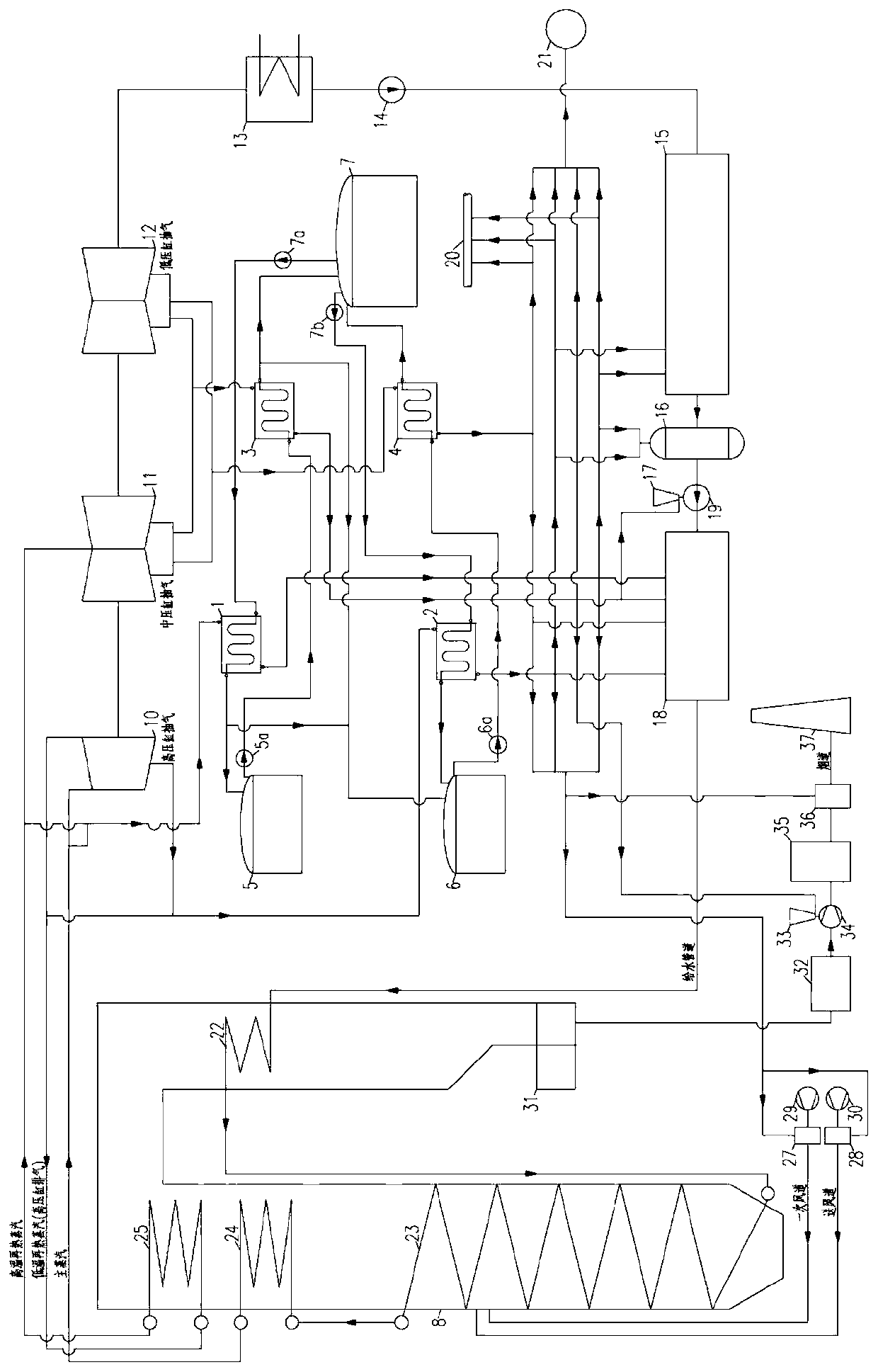

[0059] The thermal power unit in this embodiment is a once-reheating unit.

[0060] Such as figure 2 As shown, a thermal power unit molten salt cascade energy storage and discharge system includes a thermal power unit and a molten salt cascade energy storage system.

[0061] Among them, the thermal power unit includes boiler 8, main steam turbine, condenser 13, condensate pump 14, feed water pump 19, heat recovery system, feed water pump small steam turbine 17, auxiliary steam pipeline 20, induced draft fan small steam turbine 33 and flue gas system, boiler 8 Connect the main steam turbine through the steam pipeline, output the main steam to the main steam turbine, and heat the low-temperature reheated steam from the main steam turbine to the high-temperature reheated steam and send it back to the main steam turbine; The thermal system is recycled; the boiler 8 is connected to the heat recovery system through the water supply pipe, and the boiler 8 is connected to the flue g...

Embodiment 3

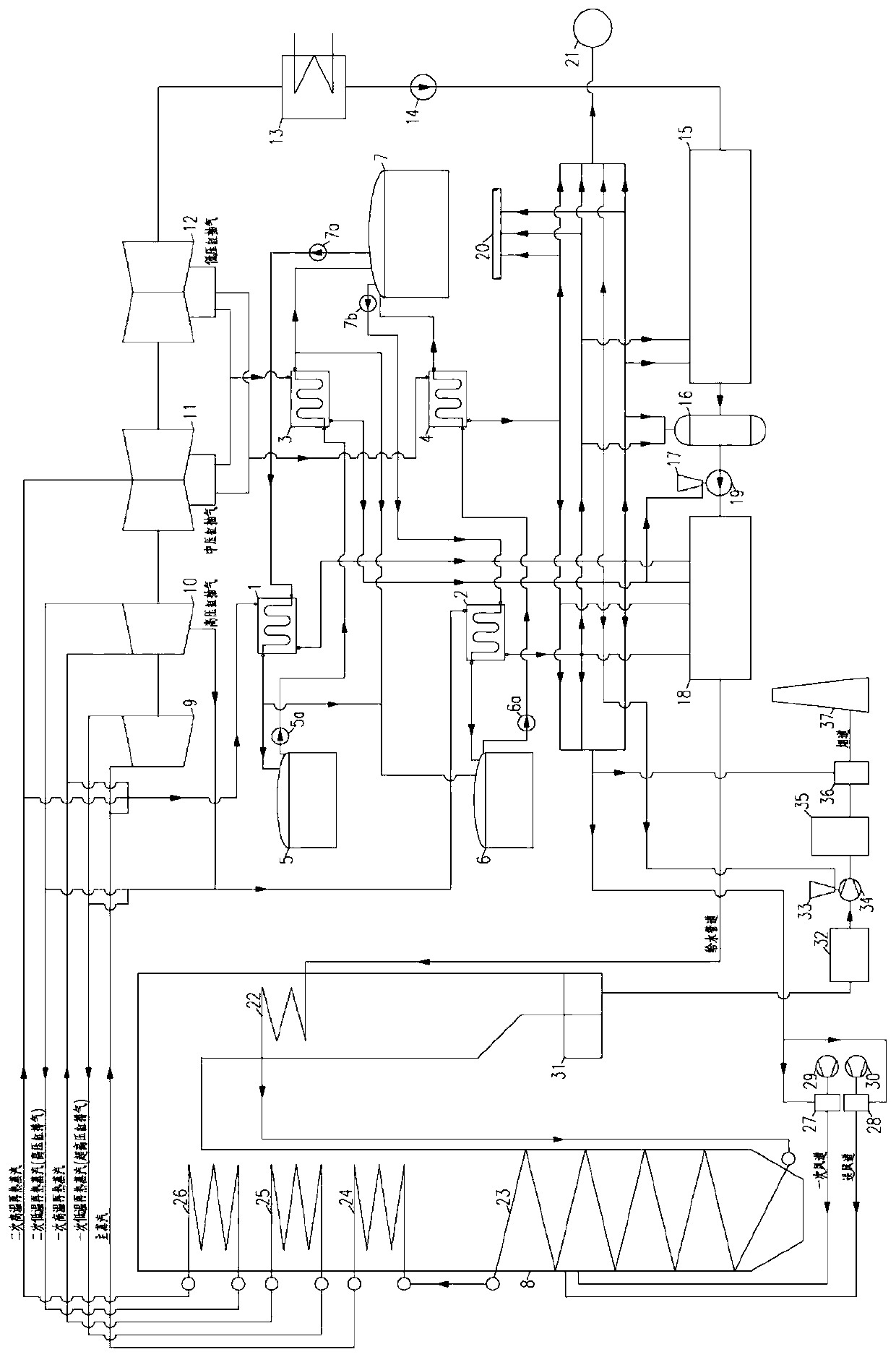

[0073] In this embodiment, the thermal power unit is a double reheat unit.

[0074] Such as image 3 As shown, a thermal power unit molten salt cascade energy storage and discharge system includes a thermal power unit and a molten salt cascade energy storage system.

[0075] Among them, the thermal power unit includes boiler 8, main steam turbine, condenser 13, condensate pump 14, feed water pump 19, heat recovery system, feed water pump small steam turbine 17, auxiliary steam pipeline 20, induced draft fan small steam turbine 33 and flue gas system, boiler 8 Connect the main steam turbine through the steam pipeline, output the main steam to the main steam turbine, and heat the low-temperature reheated steam from the main steam turbine to the high-temperature reheated steam and send it back to the main steam turbine; The thermal system is recycled; the boiler 8 is connected to the heat recovery system through the water supply pipe, and the boiler 8 is connected to the flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com