Absorption, compression and ejection composite cascade supercooling transcritical CO2 combined cooling and heating system

A combined cooling and heating, transcritical technology, applied in the fields of refrigeration and heating, heat pump, absorption refrigeration, can solve the problems of large throttling irreversible loss, increase of circulating cooling capacity, and reduction of throttling loss, etc., to reduce irreversible energy consumption. Effects of flow loss, reduction in outlet temperature, reduction in discharge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

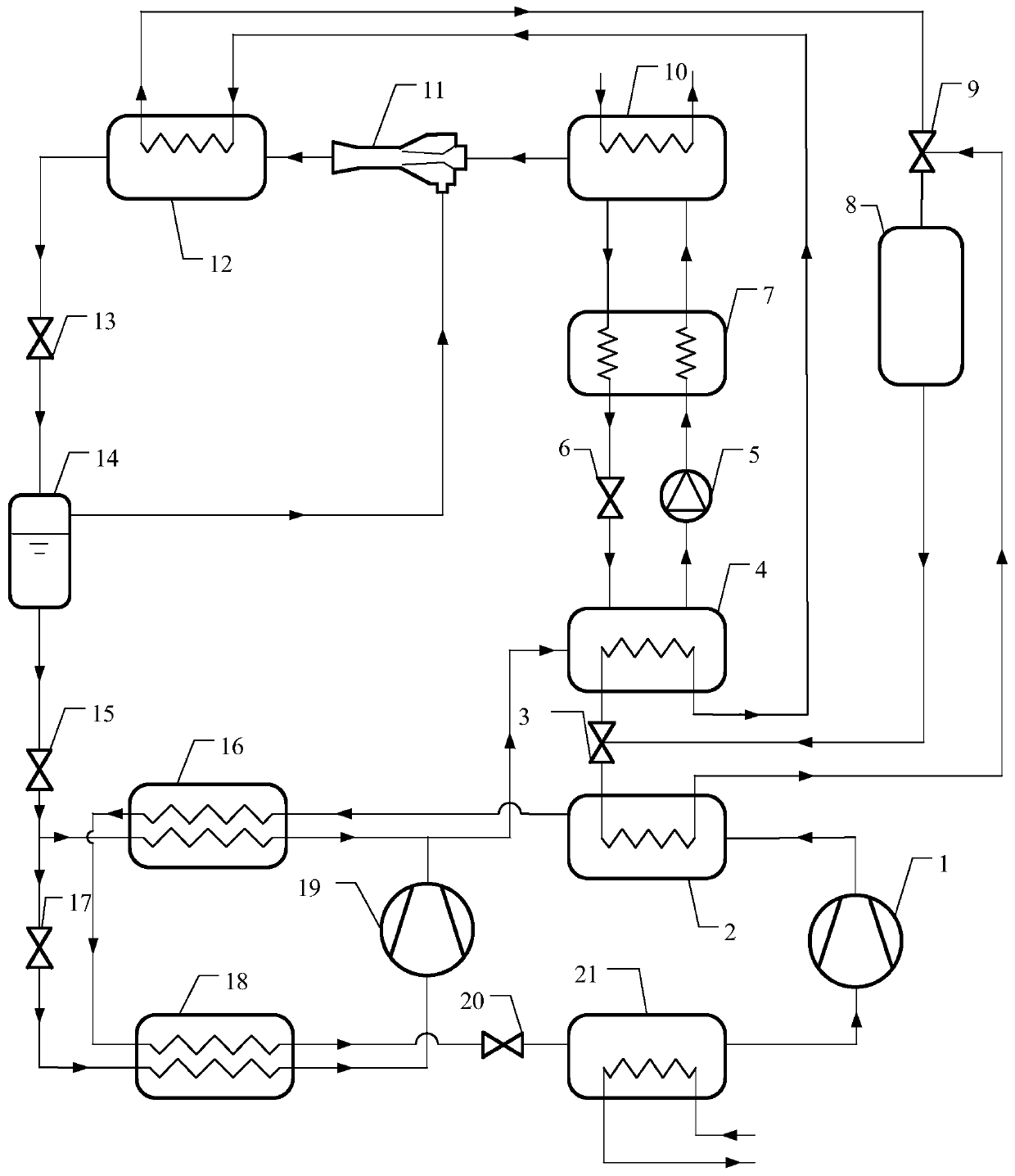

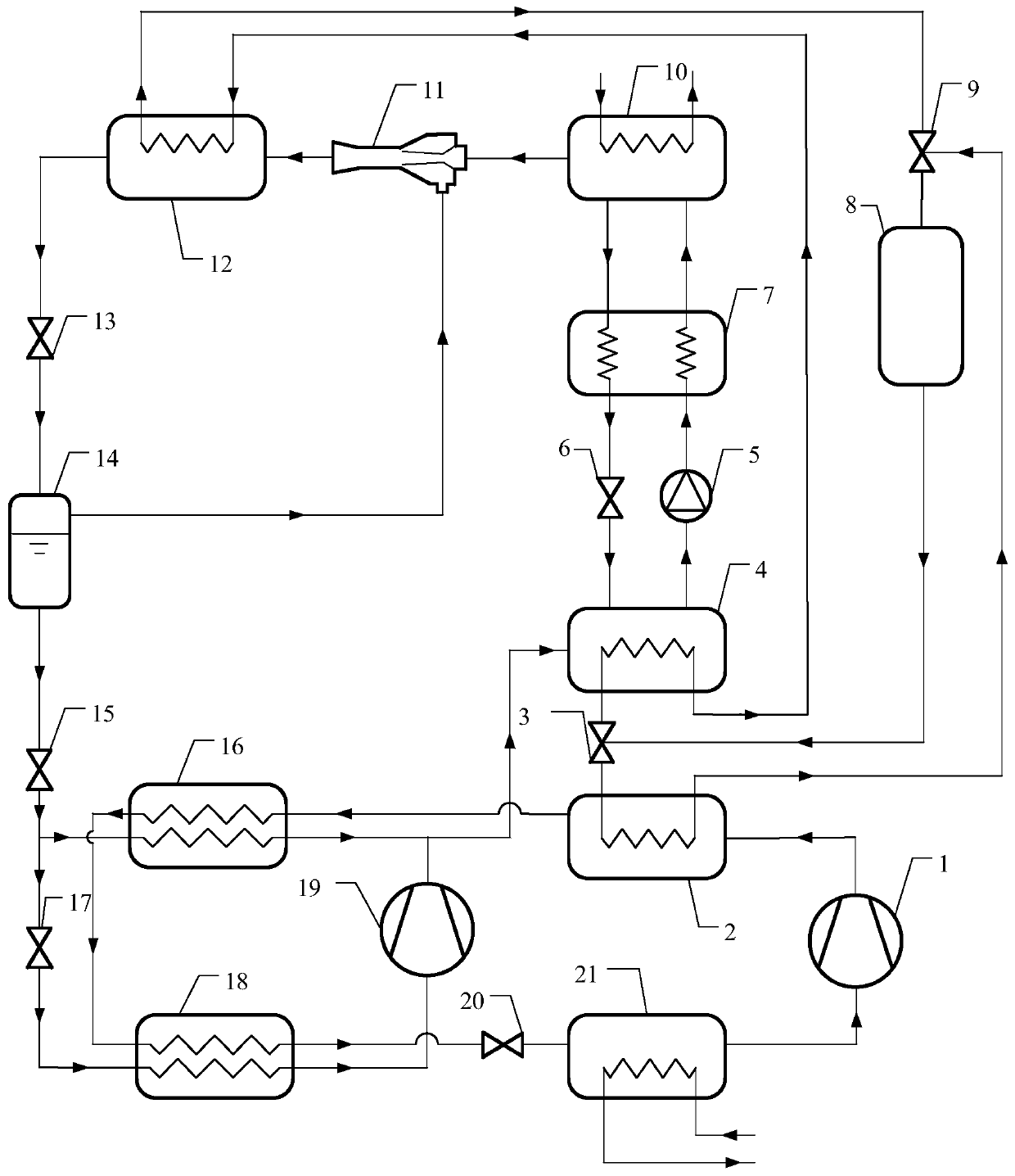

[0019] The invention consists of absorption compression ejection compound cascade subcooling cycle, transcritical CO 2 The refrigeration cycle and the hot end heating cycle are composed of a schematic diagram as figure 1 shown.

[0020] The specific implementation is as follows:

[0021] Step 1: CO 2 Low temperature and low pressure CO at the outlet of evaporator 21 2 Fluid is CO 2 Compressor 1 sucks CO compressed to high temperature and high pressure 2 fluid, then into the CO 2 The gas cooler 2 exchanges heat with the heat exchange fluid, and then flows through the primary subcooler 16CO in sequence 2 Side with secondary subcooler 18CO 2 On the side, through the refrigerant evaporation process, the heat is released twice continuously, and then flows into the CO 2 The evaporator 21 conducts evaporation and absorbs heat to complete transcritical CO 2 refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com