Treatment head, treatment system and method for treating a local surface area of a substrate

A surface area, processing head technology, applied in the field of processing head, can solve the problems of poor imprint quality, reduced output, low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

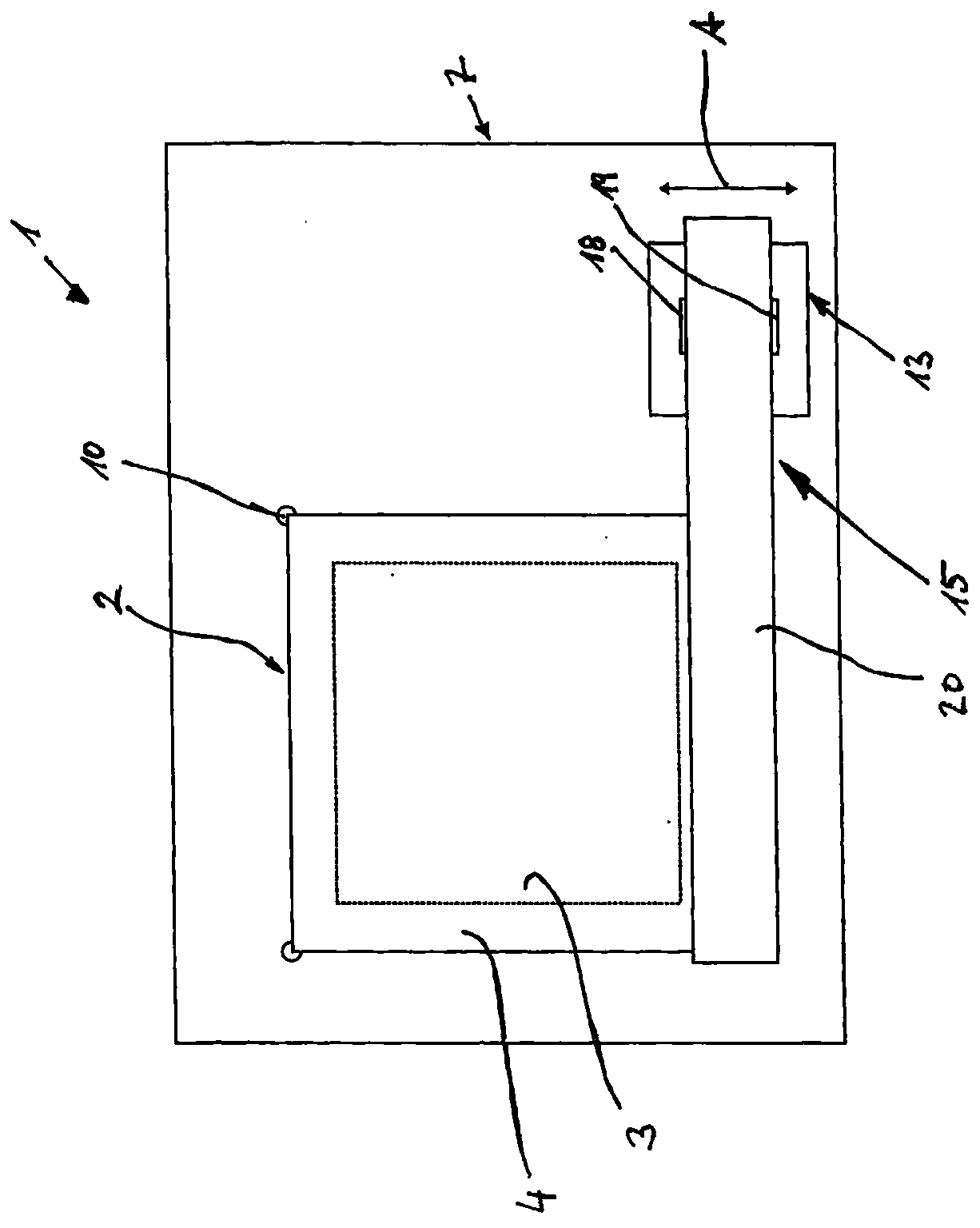

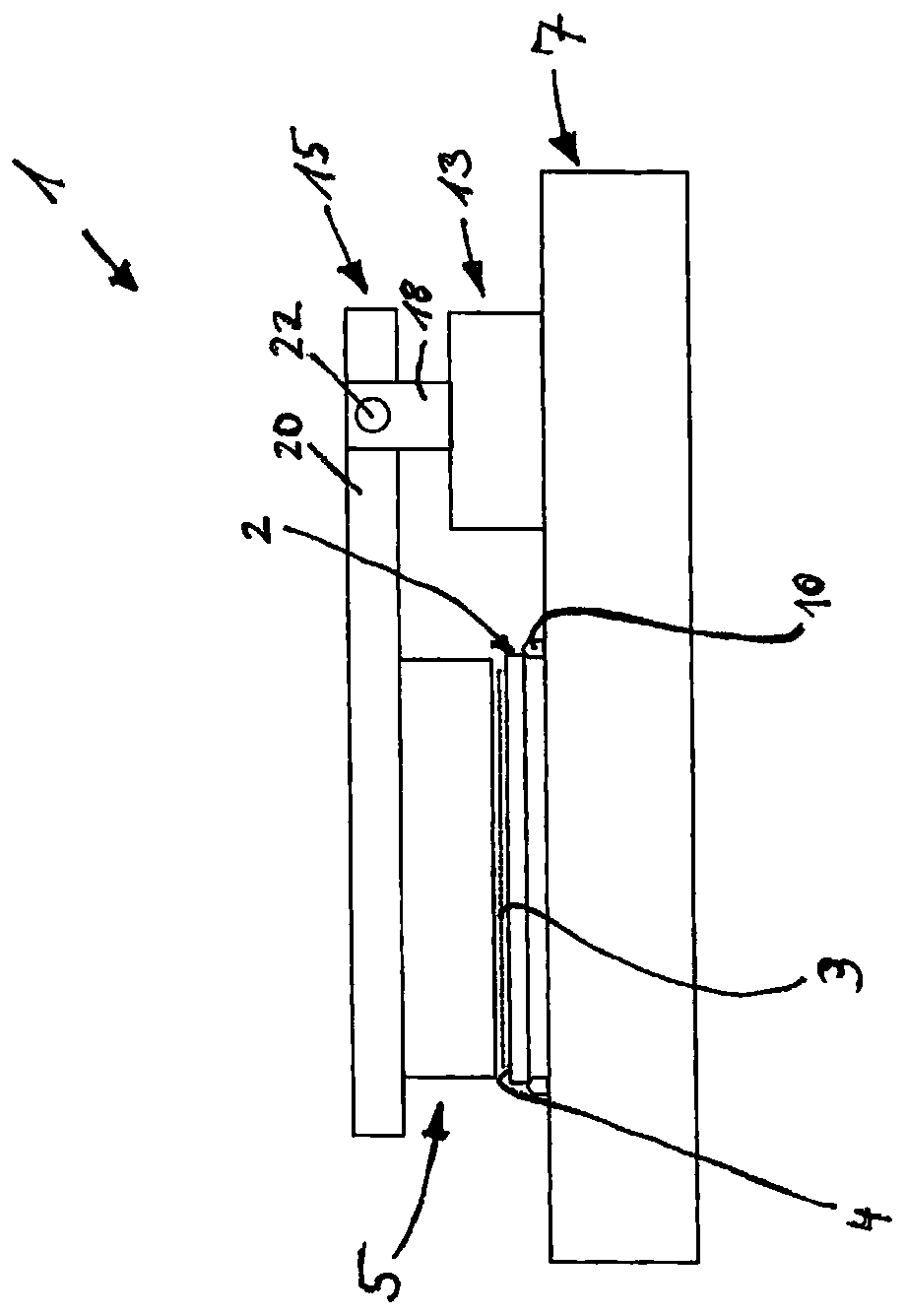

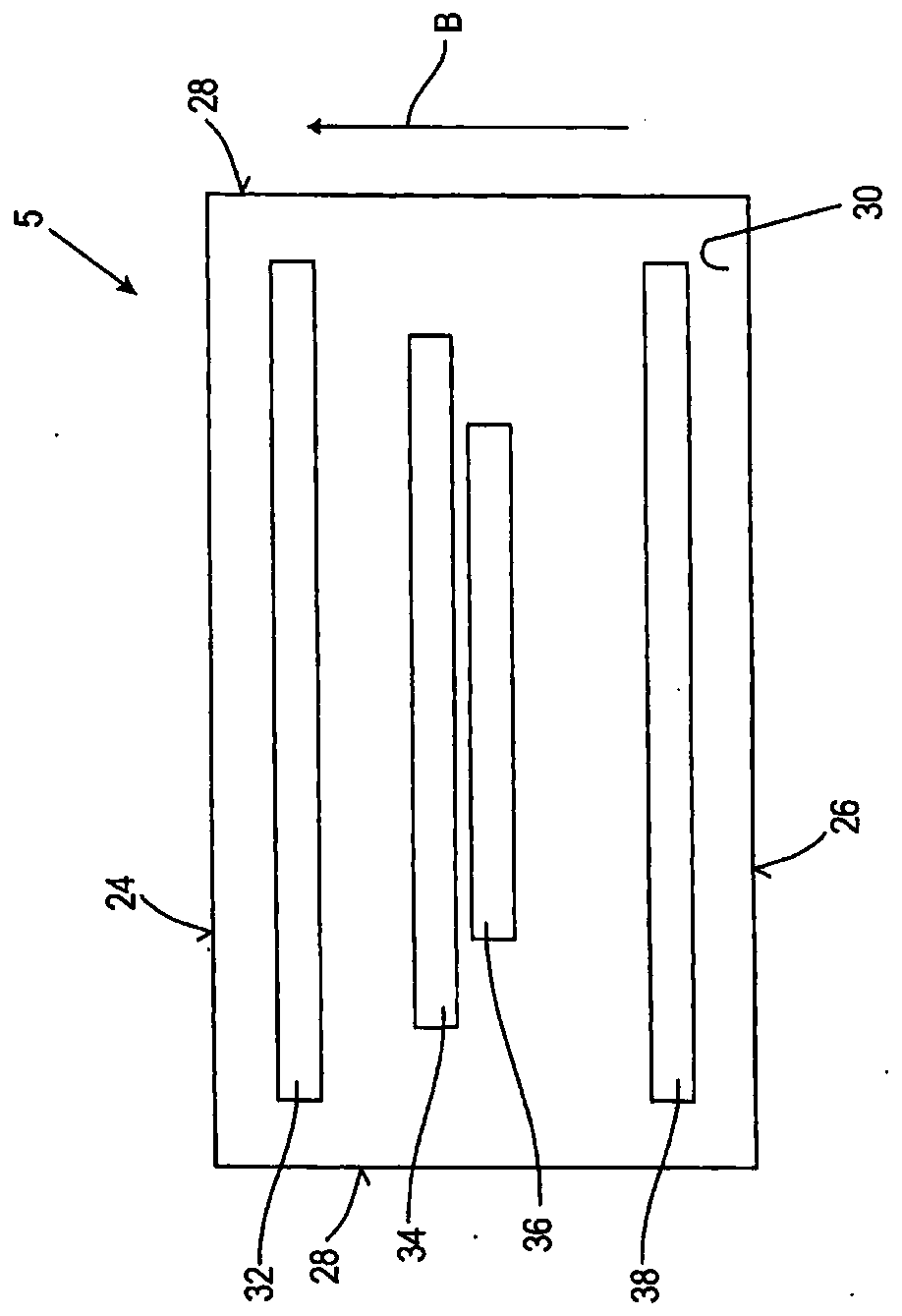

[0037] For the purposes of illustration, embodiments of the present invention will be described as being applied to cleaning a template for micro shadows, and in particular, a table area for nano-embedded micro shadows is cleaned, although obvious obvious YES, embodiments of the present invention can also be applied to cleaning different substrates or other plasma treatments for the surface of the substrate, such as surface passivation or partially using plasma to change the surface properties. The surface area of the template for nano-imprint miniane is a region directly in contact with the resist, and the resist particles may adhere to this area, which may damage the function of the template. Such resist particles are considered contaminants, and the contaminants should be removed during the cleaning process without damaging fine structures of the surface area.

[0038] The directional phrase used herein is the orientation of the components shown in the scheme, such as, left, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com