Manufacturing process of sintering-free ceramic core

A ceramic core and manufacturing process technology, which is applied in the field of sinter-free ceramic core manufacturing technology, can solve problems such as environmental pollution, corrosion of casting products, and difficulty in cleaning, so as to reduce production costs, improve production efficiency, and overcome technical prejudices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

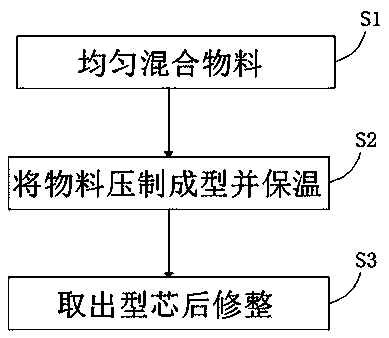

[0028] The manufacturing process of the sinter-free ceramic core of the present embodiment, such as figure 1 shown, including the following steps:

[0029] S1: Take 80 parts by mass of magnesium oxide powder, 16 parts by mass of organic adhesive, and 0.5 parts by mass of fiber and stir for 60 minutes to uniformly mix them into a viscous material;

[0030] S2: Inject the viscous material into a forming mold with a temperature of 120 degrees Celsius, and keep it warm for 240 seconds to form the viscous material;

[0031] S3: Open the mold and take out the molded material and trim it to form a ceramic core.

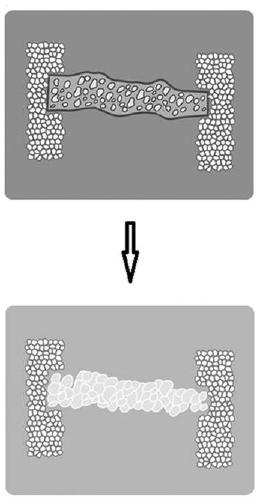

[0032] In this process, the formula of the ceramic core is adjusted, and magnesium oxide with a large expansion coefficient is used as the main material, and the organic adhesive and magnesium oxide are evenly mixed, and fibers are added to strengthen the strength of the mixed material. The above materials are evenly mixed and injected into a molding mold at 120 degrees Ce...

Embodiment 2

[0038] The organic adhesive in this embodiment includes water-based acrylic resin, wetting agent, release agent and lubricant.

[0039] The composition of the organic adhesive is shown in Table 1:

[0040] Table 1. Organic adhesive composition list (mass percentage, %)

[0041]

[0042] Water-based acrylic resin wraps magnesium oxide at room temperature and preliminarily shapes the core; the wetting agent is used to reduce the surface energy of the magnesium oxide powder, so that the magnesium oxide powder can achieve better wetting effect; the release agent is beneficial to the core forming After demoulding, there will be no bonding during the demoulding process; the role of the lubricant is to reduce the friction during the filling process, so that the viscous material can be filled with the mold smoothly. In order to achieve other properties of organic adhesives (such as thermoplasticity, thermosetting), those skilled in the art can think of other implementations withou...

Embodiment 3

[0044] The fibers are one of plastic fibers and jute fibers or a combination of both. The fiber is used to support the strength of the core after setting at room temperature. At high temperatures, the fibers are burned off and make room for the magnesium oxide to expand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com