Healthy and environment-friendly study chair back cotton material and forming method thereof

An environmentally friendly and chair back technology, applied in the field of children's learning seats, can solve problems such as odor, mildew, non-environmental protection, softness and hardness, etc., and achieve huge social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

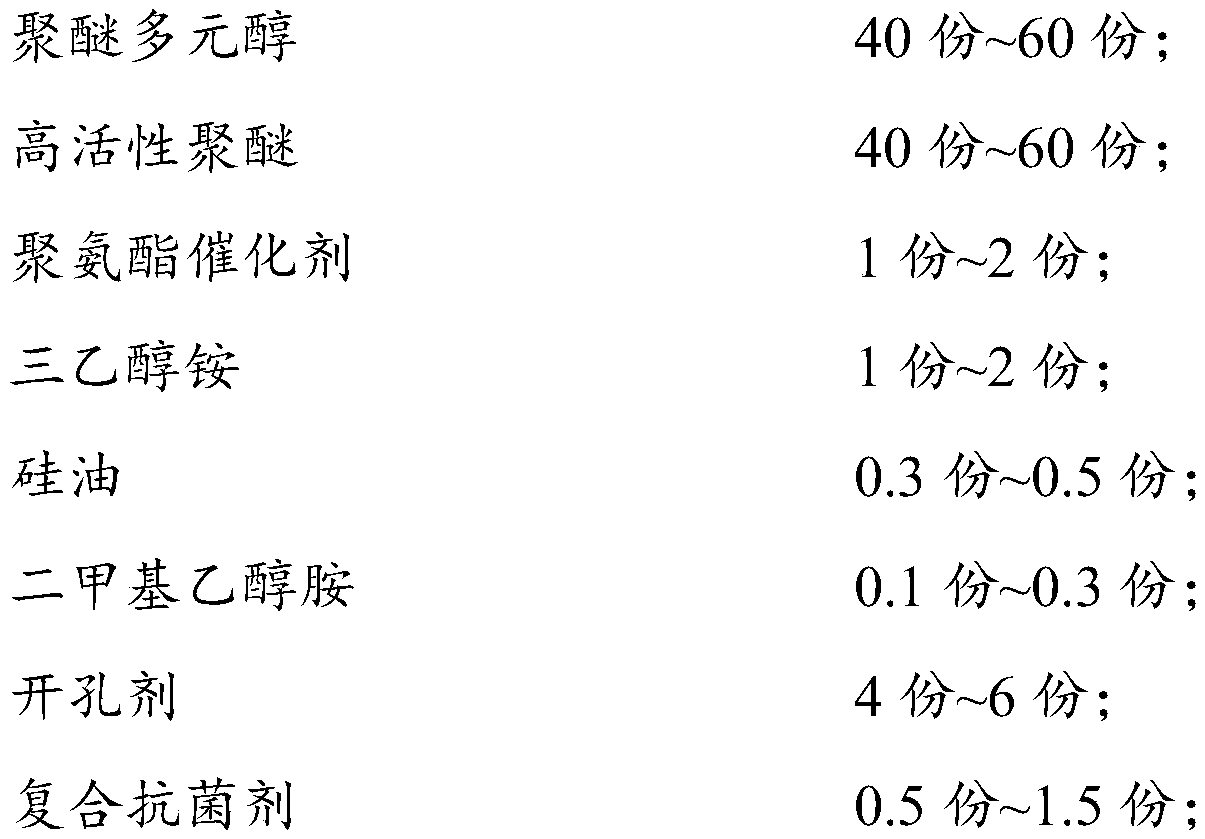

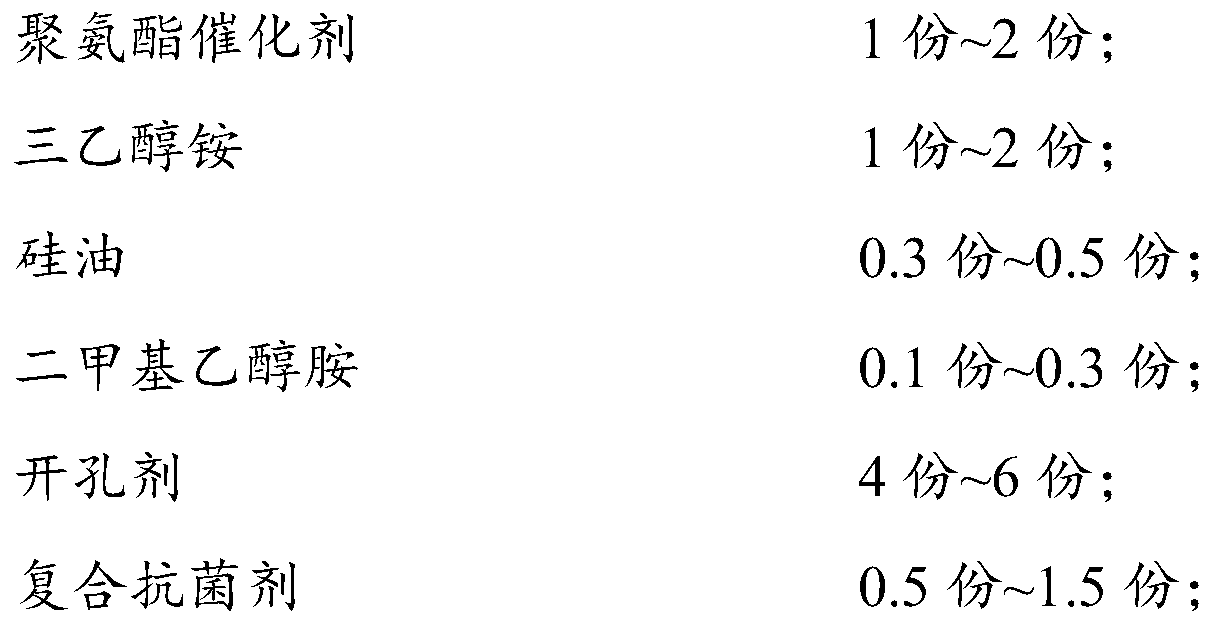

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, this embodiment provides a kind of healthy environmental protection study chair back cotton

[0023] First, according to parts by weight, 40 parts of polyether polyols, 40 parts of high-activity polyethers, 0.84 parts of triethylenediamine, 0.17 parts of delayed amine catalysts, 1 part of triethanolammonium, 0.3 parts of silicone oil, 0.1 parts of dimethylethanolamine, 4 parts of polyoxypropylene-oxyethylene copolyether, 0.5 part of composite antibacterial agent, 2 parts of water (water accounts for about 2% of the weight of component A, just stir component A until it becomes viscous) and two 44.45 parts of aminodiphenylmethane diisocyanate were weighed.

[0024] Then the polyether polyol, highly active polyether, triethylenediamine, delayed amine catalyst, triethanolammonium, silicone oil, dimethylethanolamine, polyoxypropylene-oxyethylene copolyether, composite antibacterial agent required by component A Add water and water into the mixing tank, control...

Embodiment 2

[0028] Embodiment 2, this embodiment provides a kind of healthy environmental protection study chair back cotton

[0029] First, according to parts by weight, 60 parts of polyether polyols, 60 parts of high-activity polyethers, 1.5 parts of triethylenediamine, 0.5 parts of delayed amine catalysts, 2 parts of triethanolammonium, 0.5 parts of silicone oil, 0.2 parts of dimethylethanolamine, 6 parts of polyoxyalkylene-polysiloxane copolymer, 1.5 parts of composite antibacterial agent, 4 parts of water (water accounts for about 2% of the weight of component A, just stir component A evenly until it becomes viscous) And 80 parts of diaminodiphenylmethane diisocyanate are weighed.

[0030] Then the polyether polyol, highly active polyether, triethylenediamine, delayed amine catalyst, triethanolammonium, silicone oil, dimethylethanolamine, polyoxypropylene-oxyethylene copolyether, composite antibacterial agent required by component A Add water and water into the mixing tank, control ...

Embodiment 3

[0034] Embodiment 3 This embodiment provides a healthy and environmentally friendly learning chair back cotton

[0035] First, according to parts by weight, 47.46 parts of polyether polyols, 42.19 parts of high-activity polyethers, 1.05 parts of triethylenediamine, 0.22 parts of delayed amine catalysts, 1.05 parts of triethanolammonium, 0.43 parts of silicone oil, 0.21 parts of dimethylethanolamine, 4.74 parts of polyoxypropylene-oxyethylene copolyether, 1 part of composite antibacterial agent, 2.63 parts of water (water accounts for about 2% of the weight of component A, just stir component A evenly until it becomes viscous) and two 57 parts of aminodiphenylmethane diisocyanate were weighed.

[0036] Then the polyether polyol, highly active polyether, triethylenediamine, delayed amine catalyst, triethanolammonium, silicone oil, dimethylethanolamine, polyoxypropylene-oxyethylene copolyether, composite antibacterial agent required by component A Add water and water into the mi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap