A kind of low thermal resistance type low smoke halogen free cable material for ships and preparation method thereof

A technology of low thermal resistance and cable material, which is applied in the field of low thermal resistance low-smoke halogen-free cable material for ships and its preparation, can solve the problems of no heat conduction research, achieve the effect of reducing heat conduction cost, improving thermal conductivity and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In Example 1 and Example 2, the mass ratio of benzoxazine / aluminum nitride is 5:3, which can achieve a better effect of resin-wrapped filler, and its tensile strength and thermal conductivity are greatly improved, and due to benzene The addition amount of the oxazine / aluminum nitride thermally conductive filler is increased from 16 parts to 24 parts in Examples 1 to 2, and the thermal conductivity and tensile strength increase with the increase of its addition amount, but due to the consideration of cost, this patent is the highest Just add it to 30 servings, and it already has a significant performance improvement.

Embodiment 3

[0070] The added total mass of the benzoxazine / aluminum nitride thermally conductive filler of Example 3 and Example 4 is the same as that of Example 2, but the difference is that the mass ratio of benzoxazine / aluminum nitride in Example 3 is 5: 1. The mass ratio of benzoxazine / aluminum nitride in Example 4 is 1:1.

[0071] From the test data, it can be seen that in Example 3, due to the small proportion of thermally conductive fillers, although the benzoxazine resin increases the crosslinking density and also increases thermal conductivity, the main factor that increases thermal conductivity is aluminum nitride, which can be formed in polymers. Therefore, the tensile strength in Example 3 can reach 18.6Mpa due to the addition of benzoxazine, but the real number of thermal conductivity is only 1.3.

Embodiment 4

[0072] In Example 4, the proportion of thermally conductive fillers is high, but the benzoxazine resin is not enough to cover it completely. In this way, although a lot of aluminum nitride is added, the distribution is not uniform, and good thermal conductivity cannot be achieved. In addition, the proportion of benzoxazine resin is small, and the contribution to the improvement of crosslinking density is small, and the natural tensile strength is not as good as the implementation. Example 2.

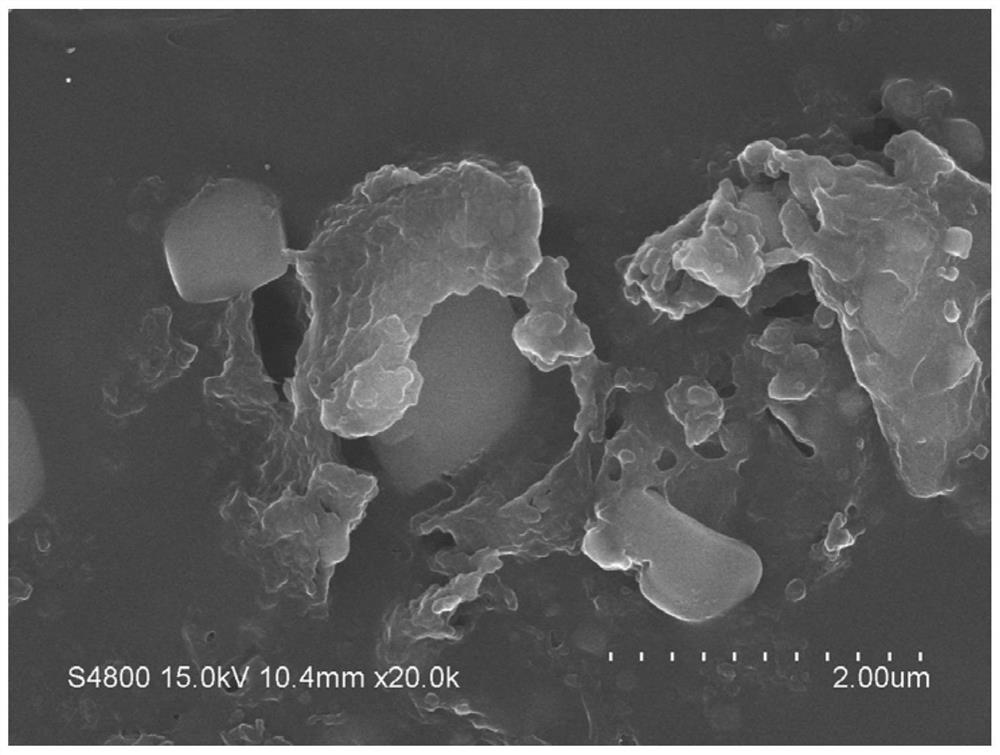

[0073] figure 1 It is a 5:3 thermal conductive filler wrapping situation (the continuous phase is benzoxazine resin - examples 1, 2); figure 2 It is a 5:1 thermally conductive filler wrapping situation (the continuous phase is benzoxazine resin-Example 3); image 3 It is a 1:1 encapsulation of thermally conductive filler (continuous phase is benzoxazine resin - Example 4).

[0074] The advantages of using benzoxazine / aluminum nitride thermally conductive fillers to improve thermal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com