Water-based ceramic material for inner tank of stainless steel thermos cup and preparation method thereof

A ceramic coating, water-based technology, applied in the direction of coating, etc., can solve the problems that the environmental protection and health of the cup cannot be guaranteed, and achieve the effects of avoiding health problems, delaying heat conduction, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

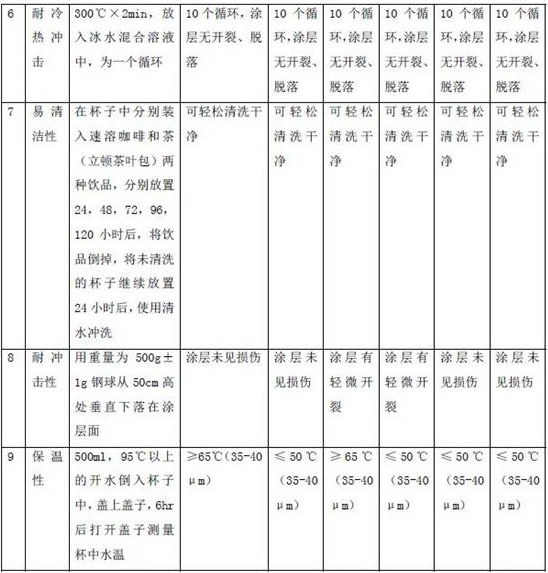

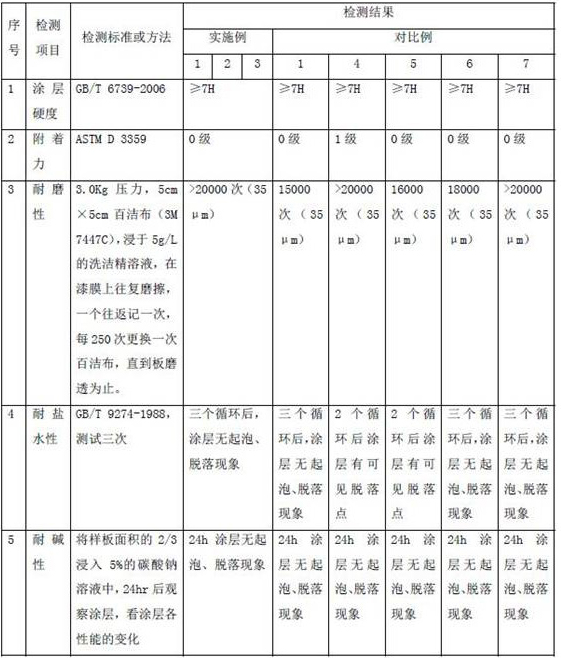

Examples

Embodiment 1~3

[0047] Examples 1 to 3 respectively relate to a water-based ceramic coating for the inner tank of a stainless steel thermos cup, and its composition and dosage by weight are shown in Table 1;

[0048] The preparation process is as follows:

[0049] (1) Grinding color paste: After mixing sol, inorganic pigments, fillers, and deionized water, grind at 1300 rpm to a fineness below 18 μm, control the pH value to >8.2, then add acrylic resin, reduce the speed to 170rmp, and React under alkaline conditions for 45 minutes to obtain the color paste;

[0050] (2) Add acetic acid to the color paste, stir evenly, and control the pH value between 3.9-4.3;

[0051] (3) Continue to add methyltrimethoxysilane, dimethyldiethoxysilane, aminopropyltrimethoxysilane, and hydroxyl silicone oil, react at 180rmp for 6 hours, and let it stand; the water-based ceramic coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com