Method for preparing straight-chain dextrins

A straight-chain dextrin and membrane separation technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of low dextrin yield and wide molecular weight distribution, and achieve The effect of low production cost, less environmental pollution, and uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

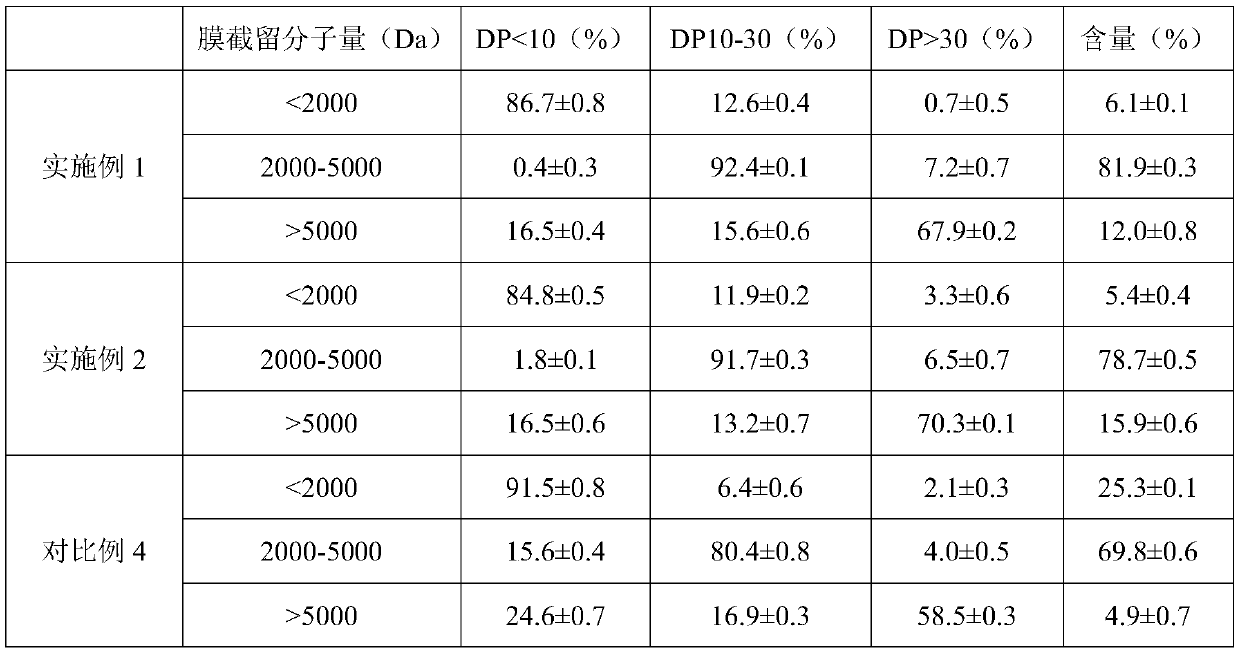

Embodiment 1

[0041] (1) Ultrasonic declustering: Prepare 5%-10% waxy cornstarch milk, stir it evenly, and then ultrasonically treat it. The processing time is 10min;

[0042] (2) Ultrasonic complexation: Add waxy corn starch quality 5% glyceryl monostearate to the starch milk after ultrasonic treatment, stir evenly, the ultrasonic working frequency is 20kHz, processing power is 500W, temperature 40 ℃, every The time of each action is 3s, the interval is 5s, and the total ultrasonic time is 20min;

[0043] (3) Composite enzymatic hydrolysis: adjust the pH of the starch-glycerol monostearate complex solution to 6.0 with phosphate buffer, heat in a water bath to 50°C, add medium-temperature α-amylase and pullulanase, pullulanase The addition amount is 30 ASPU / g dry starch, the addition amount of α-amylase is 30 ASPU / g dry starch, and the water bath is hydrolyzed at 50°C for 3-4 hours. Boiling water bath for 5 minutes to inactivate medium-temperature α-amylase and pullulanase to terminate th...

Embodiment 2

[0048] (1) Ultrasonic declustering: Prepare 5%-10% waxy cornstarch milk, stir it evenly, and then ultrasonically treat it. The processing time is 10min;

[0049](2) Ultrasonic complexation: add palmitic acid of waxy corn starch quality 3% in the starch milk after ultrasonic treatment, stir evenly, ultrasonic working frequency is 20kHz, processing power is 500W, temperature is 40 ℃, each action time is 3s, interval 5s, total ultrasound time 20min;

[0050] (3) Composite enzymatic hydrolysis: adjust the pH of the starch-palmitic acid complex solution to 6.0 with phosphate buffer, heat in a water bath to 50°C, add medium-temperature α-amylase and pullulanase, and the amount of pullulanase added is 40 ASPU / g dry starch, the amount of α-amylase added is 20ASPU / g dry starch, and hydrolyzed in a water bath at 50°C for 3-4h. Boiling water bath for 5 minutes to inactivate medium-temperature α-amylase and pullulanase to terminate the reaction, and centrifuge to obtain the supernatant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com