Clothes washing equipment

A technology for laundry washing and equipment, which is applied to washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of small amount, complex structure of micro-bubble generating device, large size of micro-bubble, etc. The effect of prolonged time and small bubble size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

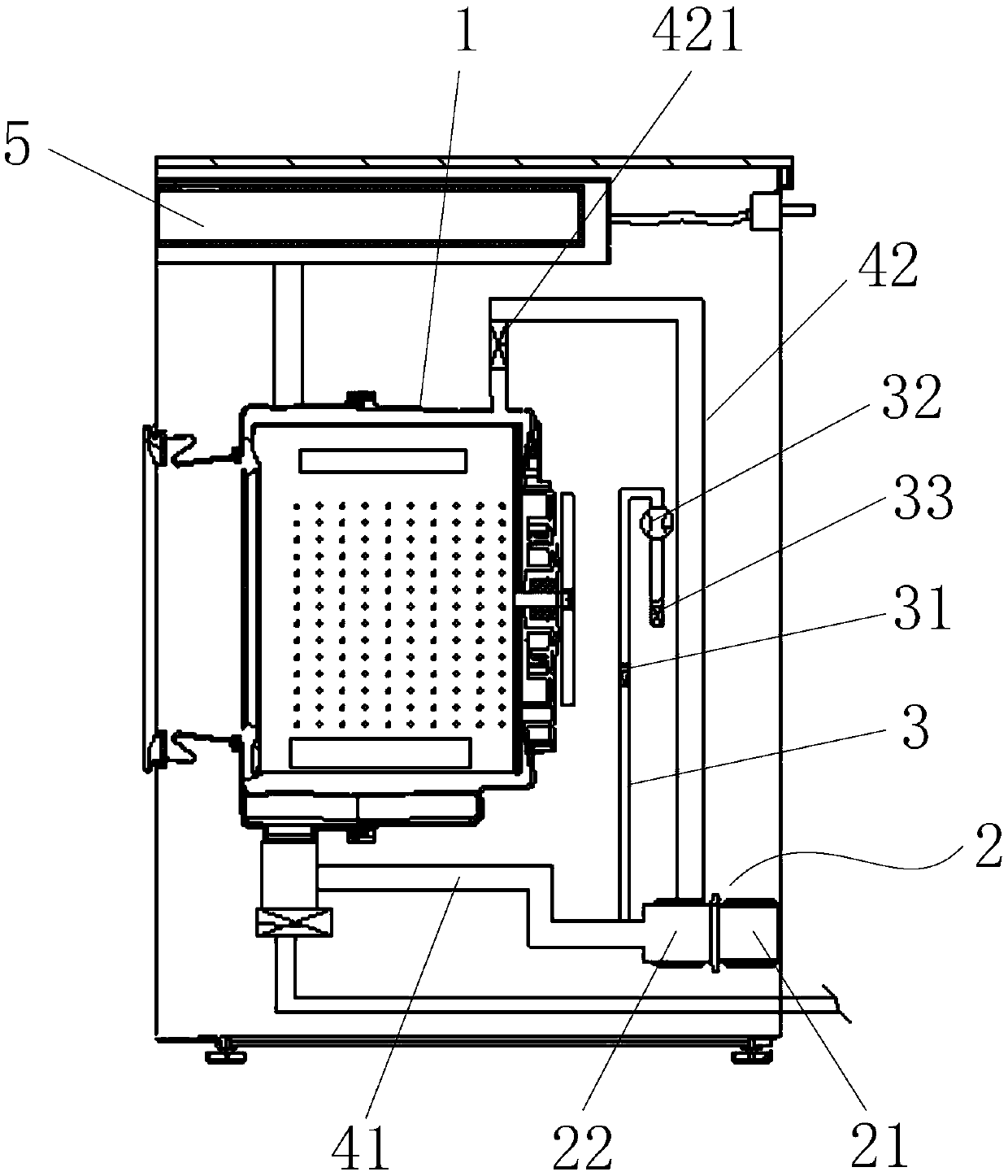

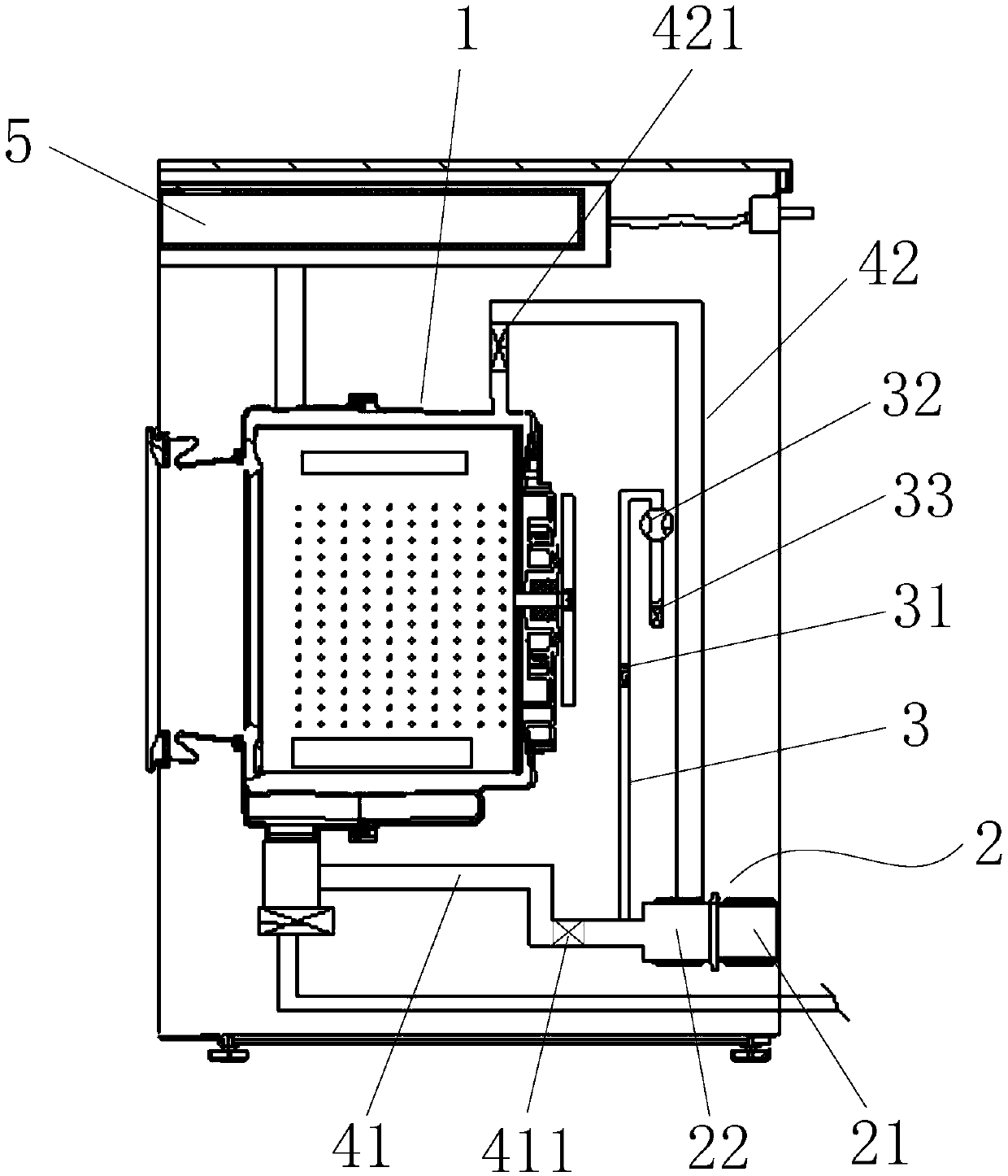

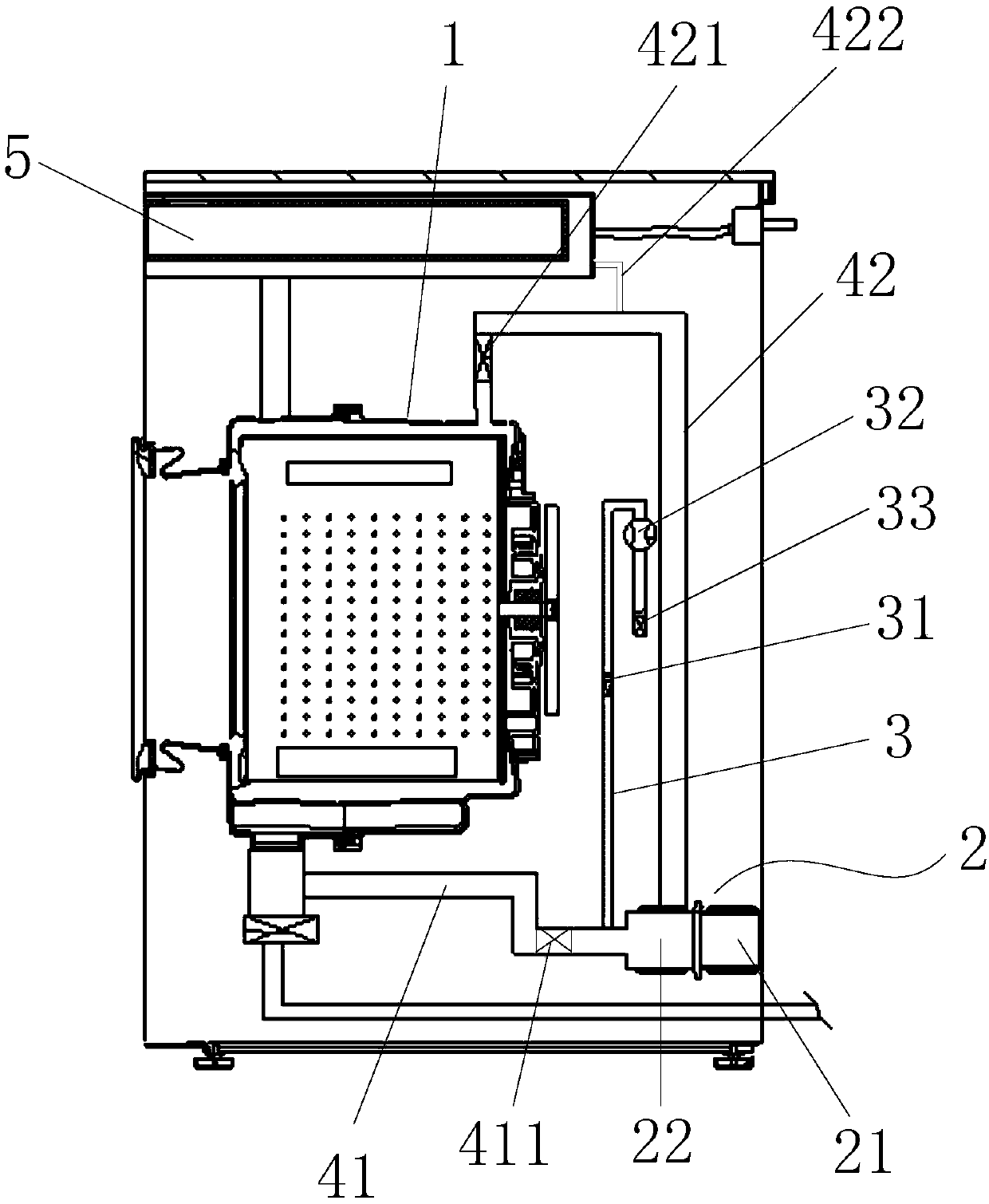

Image

Examples

Embodiment Construction

[0024] Those skilled in the art should understand that the embodiments in this section are only used to explain the technical principle of the present invention, and are not used to limit the protection scope of the present invention. For example, although this embodiment describes and illustrates the laundry washing equipment of the present invention in combination with a drum washing machine, this is not a limitation to the laundry washing equipment of the present invention, such as a top-wheel washing machine, an integrated washing and drying machine and Shoe washing machine and so on. Those skilled in the art can make adjustments as needed so as to adapt to specific application occasions, and the adjusted technical solutions will still fall within the protection scope of the present invention.

[0025] It should be noted that, in the description of the present invention, the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer" etc. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap