Oilless air compressor of integrated air circuit

An oil-free air compressor and air circuit technology, which is used in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. The problem of less heat dissipation in the gas pipeline can achieve the effect of increasing aesthetics, beautiful appearance and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

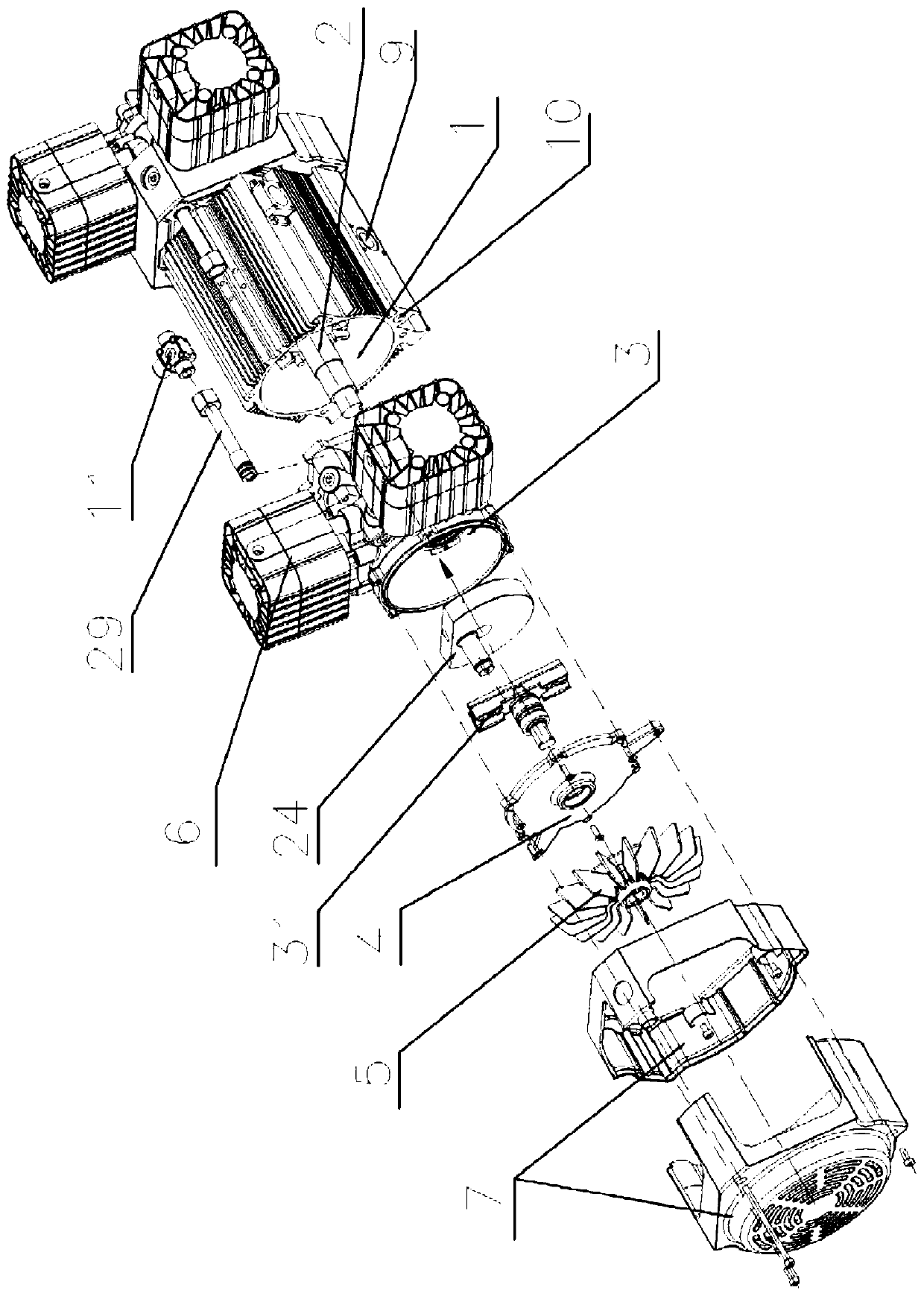

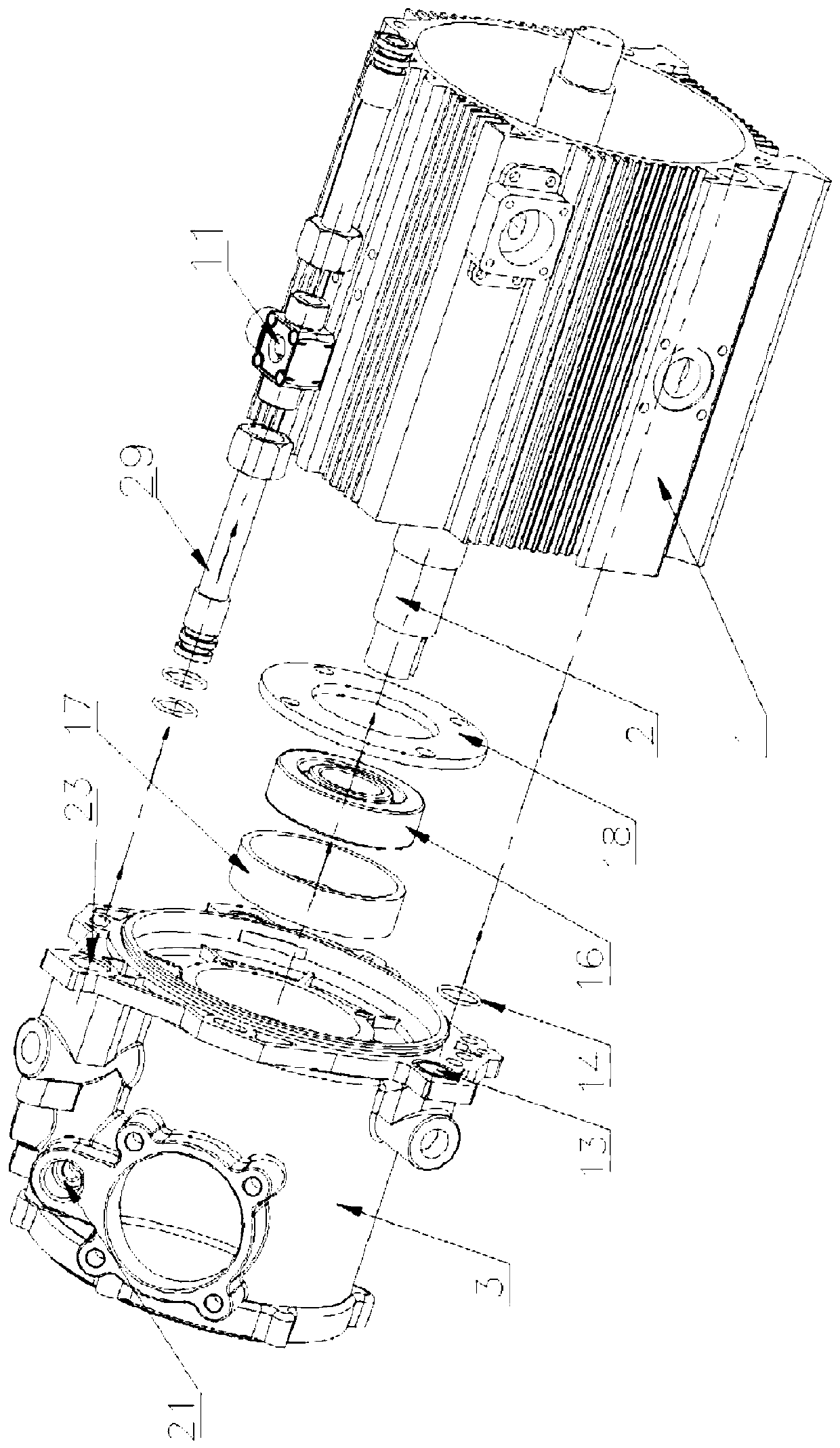

[0043] Figure 1-Figure 7 As shown, it is an embodiment of the present invention, an oil-free air compressor with an integrated air circuit, its structure mainly includes a motor casing 1, a motor shaft 2, a crankcase 3, a side cylinder cover 4, a cooling fan 5, and a cylinder 6 , air guide cover 7, fan connection assembly 31; (as figure 1 )

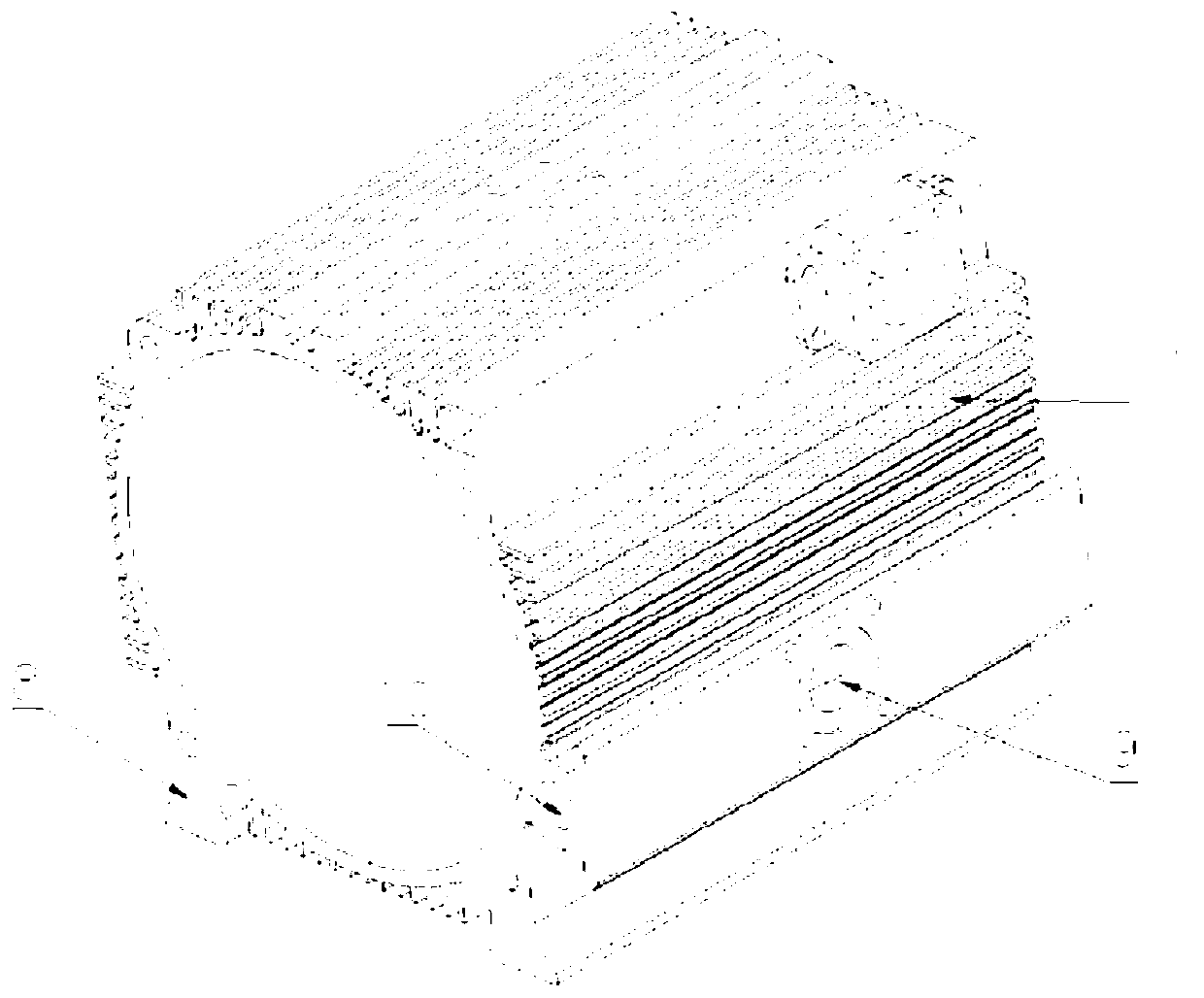

[0044] We adopt horseshoe-shaped structure 8 for the base of the motor casing, the purpose is to simplify the weight while ensuring the supporting strength, thereby reducing the cost; (such as figure 2 )

[0045] The gas flows into the intake pipe 10 from the motor air inlet 9, and then flows into the crankcase 3, and the intake pipe 10 is integrated on the motor casing 1, so that the pipeline is built in, and the advantage is to reduce the number of external pipes, Reduce costs, and can also dissipate heat to the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com