Novel integrated device for igniting by atomizing fuel oil through steam

A technology for atomizing fuel oil and an integrated device, which is used in combustion ignition, fluidized bed combustion equipment, and ignition through guide flares, etc., can solve problems such as unstable atomization effect of oil guns, and achieve unstable mechanical atomization effect. The effect of low material and processing requirements and fast burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

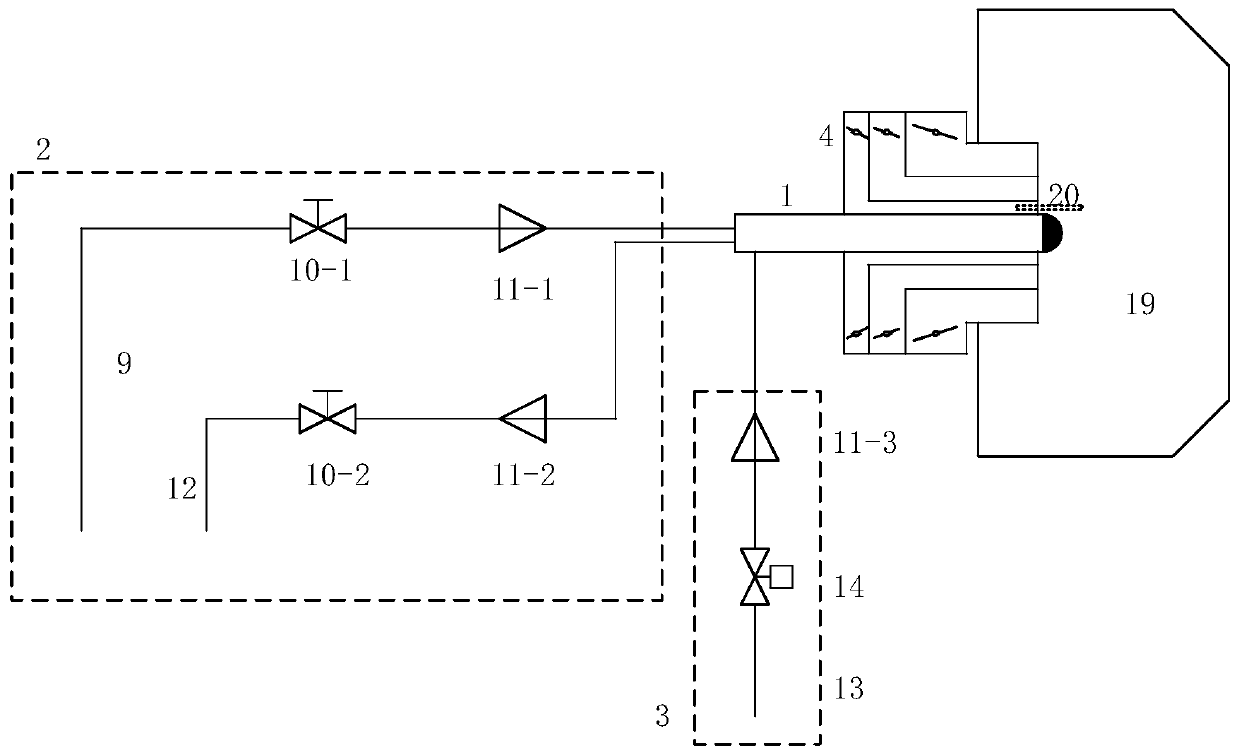

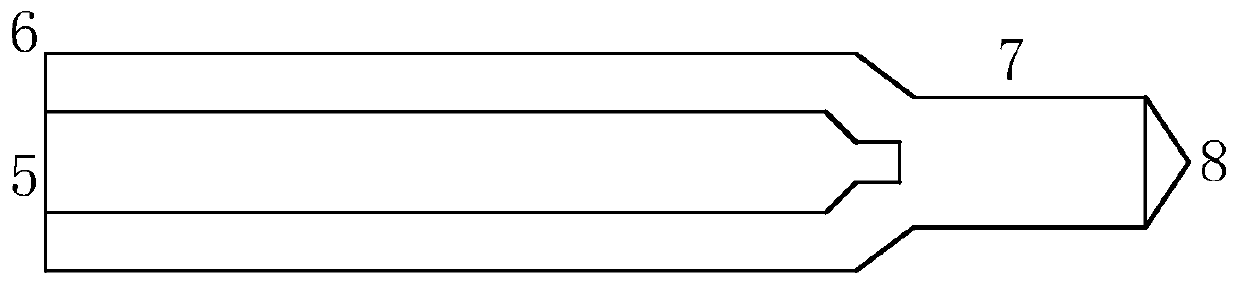

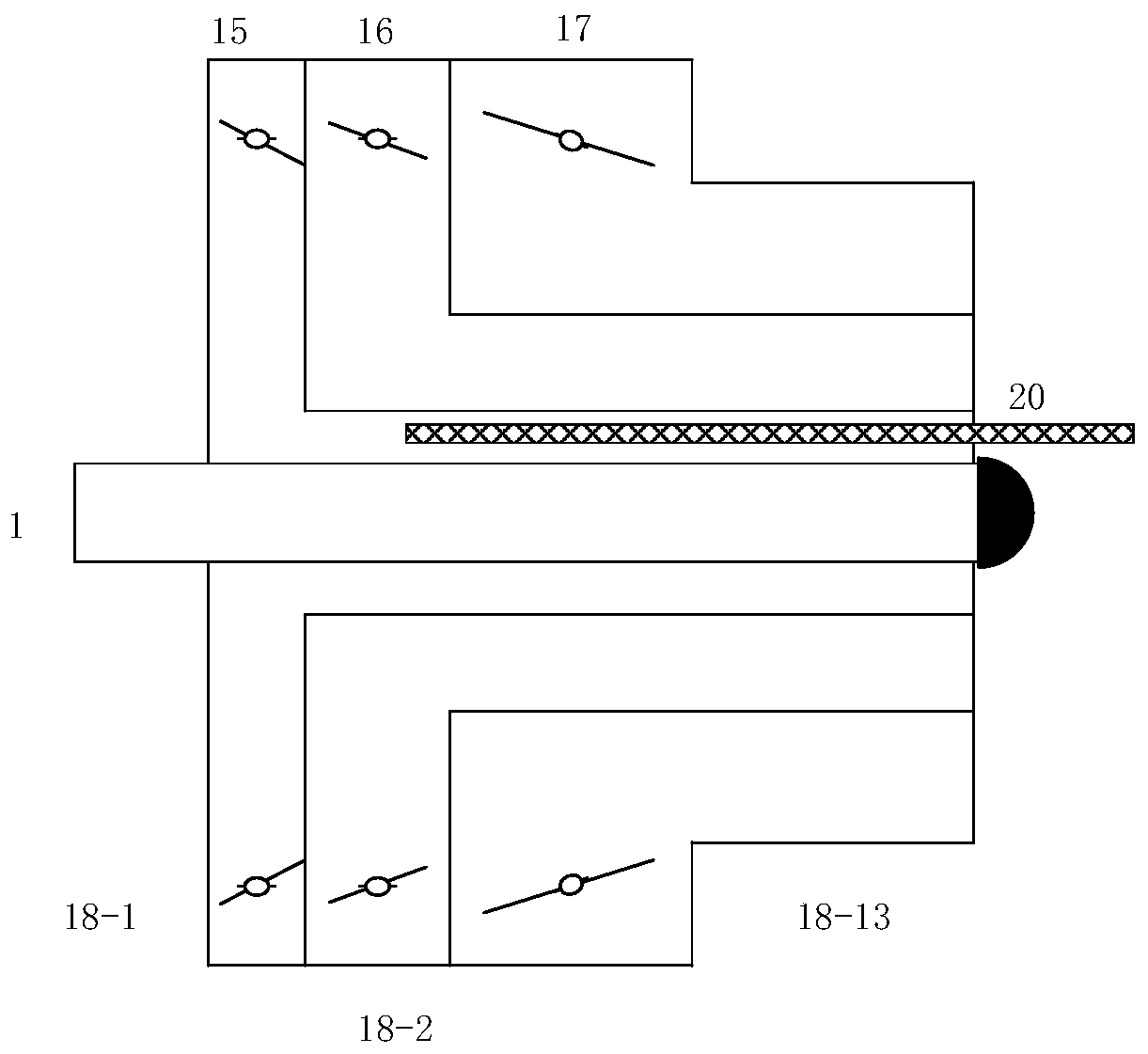

[0023] Such as Figure 1 to 3 As shown, the present invention provides a new type of vapor atomized fuel ignition integrated device, including oil gun 1, fuel system 2, vapor system 3, air regulator 4, fuel passage 5, vapor passage 6, mixing chamber 7, nozzle 8. , Oil inlet pipe 9, the first pressure regulating valve 10-1, the second pressure regulating valve 10-2, the first one-way check valve 11-1, the second one-way check valve 11-2, the third single Reverse check valve 11-3, oil return header 12, steam header 13, valve 14, fuel air channel 15, cooling air channel 16, primary air channel 17, fuel air baffle 18-1, cooling air baffle 18 -2. The primary air baffle 18-3, the air chamber 19 and the ignition gun 20, wherein the oil gun 1 includes a fuel passage 5, a vapor passage 6, a mixing chamber 7 and a nozzle 8, and the outlet of the fuel passage 5 and The outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com