SNCR urea atomization spray gun, and denitration system and process

A technology of atomizing spray gun and urea, which is applied in spraying devices, liquid spraying devices, chemical instruments and methods, etc., can solve the problems of easy burning, high cost of high-pressure compressed air, high energy consumption, and reduced denitrification efficiency, etc., and achieves good results. High temperature performance and corrosion resistance, low material and processing requirements, easy to achieve the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

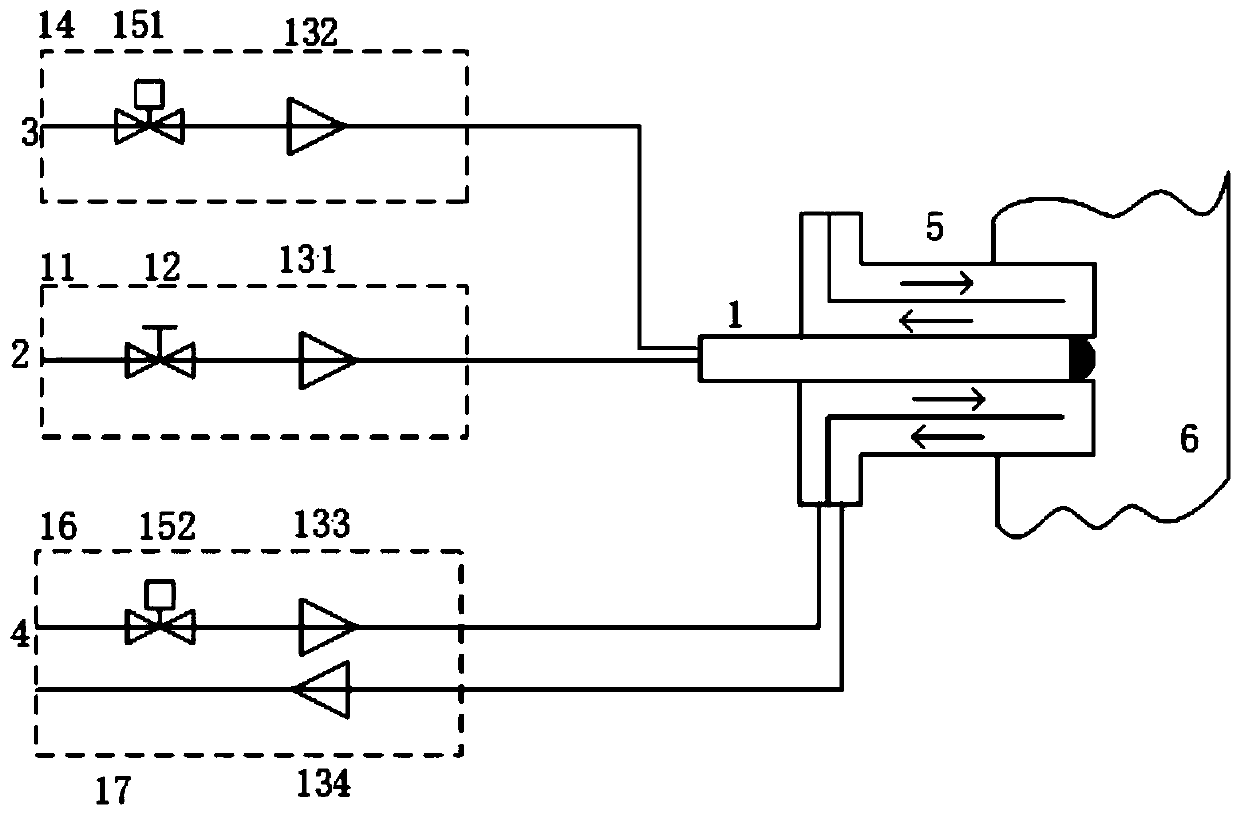

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments

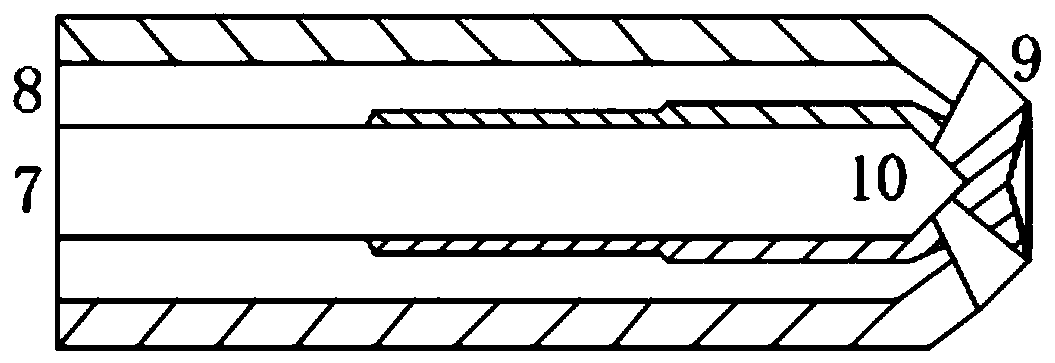

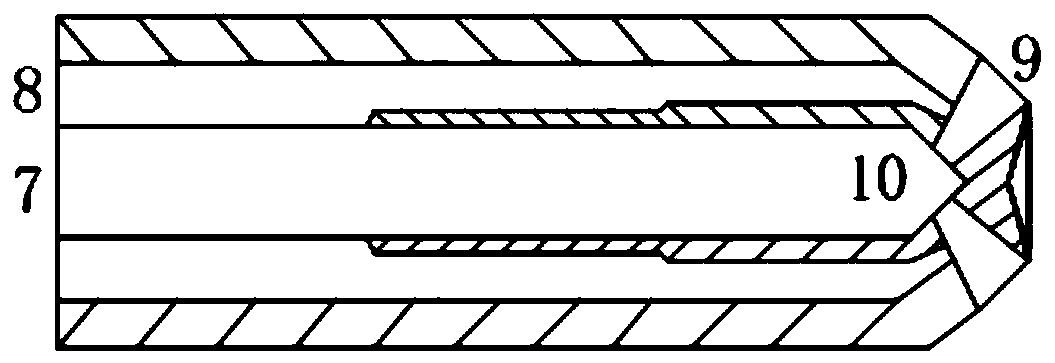

[0033] Such as figure 2 As shown, a SNCR urea atomizing spray gun includes a steam tube 7, a urea tube 8 and a mixing hole 9. The steam tube 7 is arranged in the core of the spray gun, and the urea tube 8 is arranged one round outside the steam tube 7 along the steam tube 7 A number of mixing holes 9 are provided on the outlet end surface 10 of the, the mixing holes 9 are connected to the steam tube 7 and the urea tube 8; the outside of the urea tube 8 is provided with a water-cooled sleeve 5 which is connected to the circulating cooling water main pipe 16; the water-cooled sleeve 5 There are two layers, the inner layer is connected to the circulating cooling water inlet pipe, and the outer layer is connected to the circulating cooling water outlet pipe, such as figure 2 As shown, both the circulating cooling water inlet pipe and the circulating cooling wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com