Wastewater zero emission device and technology

A wastewater and zero-discharge technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to adapt to environmental protection policies, unstable effluent quality, and complex system operations. , to achieve the effect of reducing civil construction investment, intensive equipment integration, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

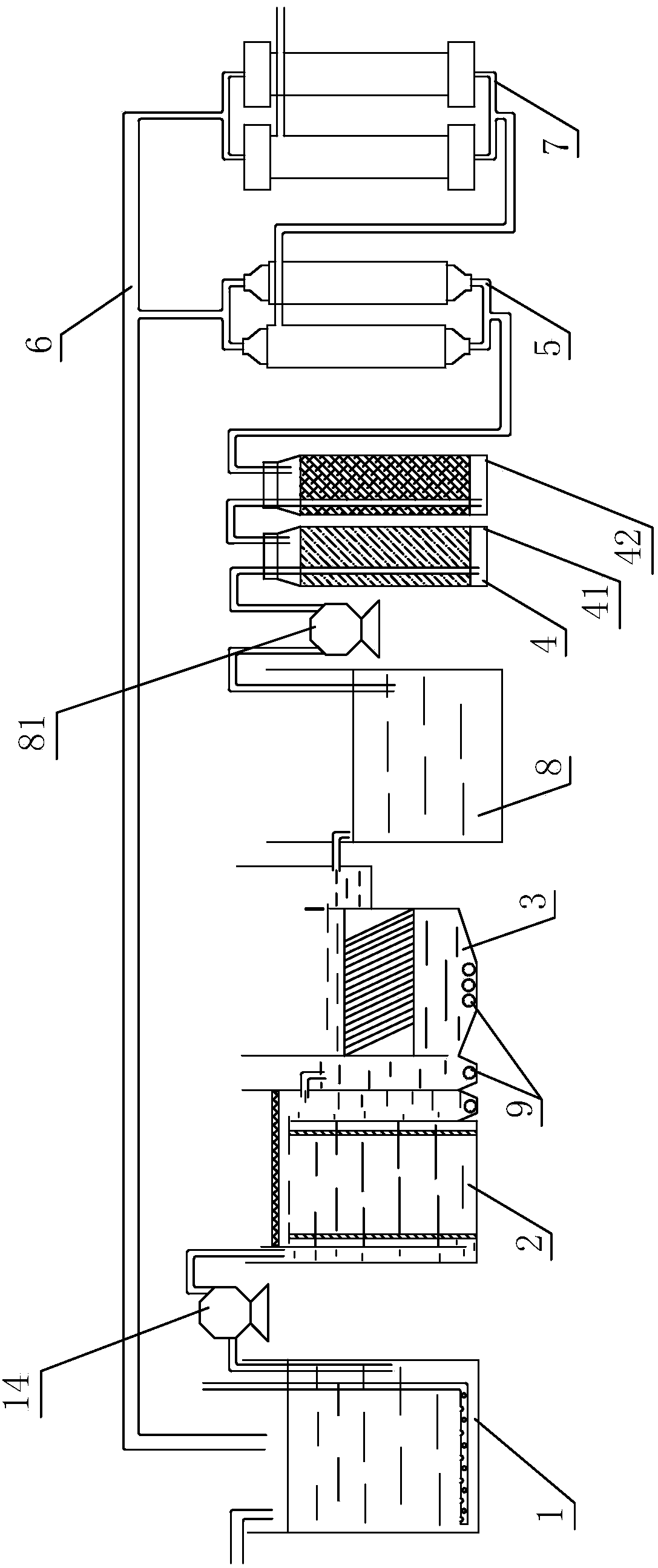

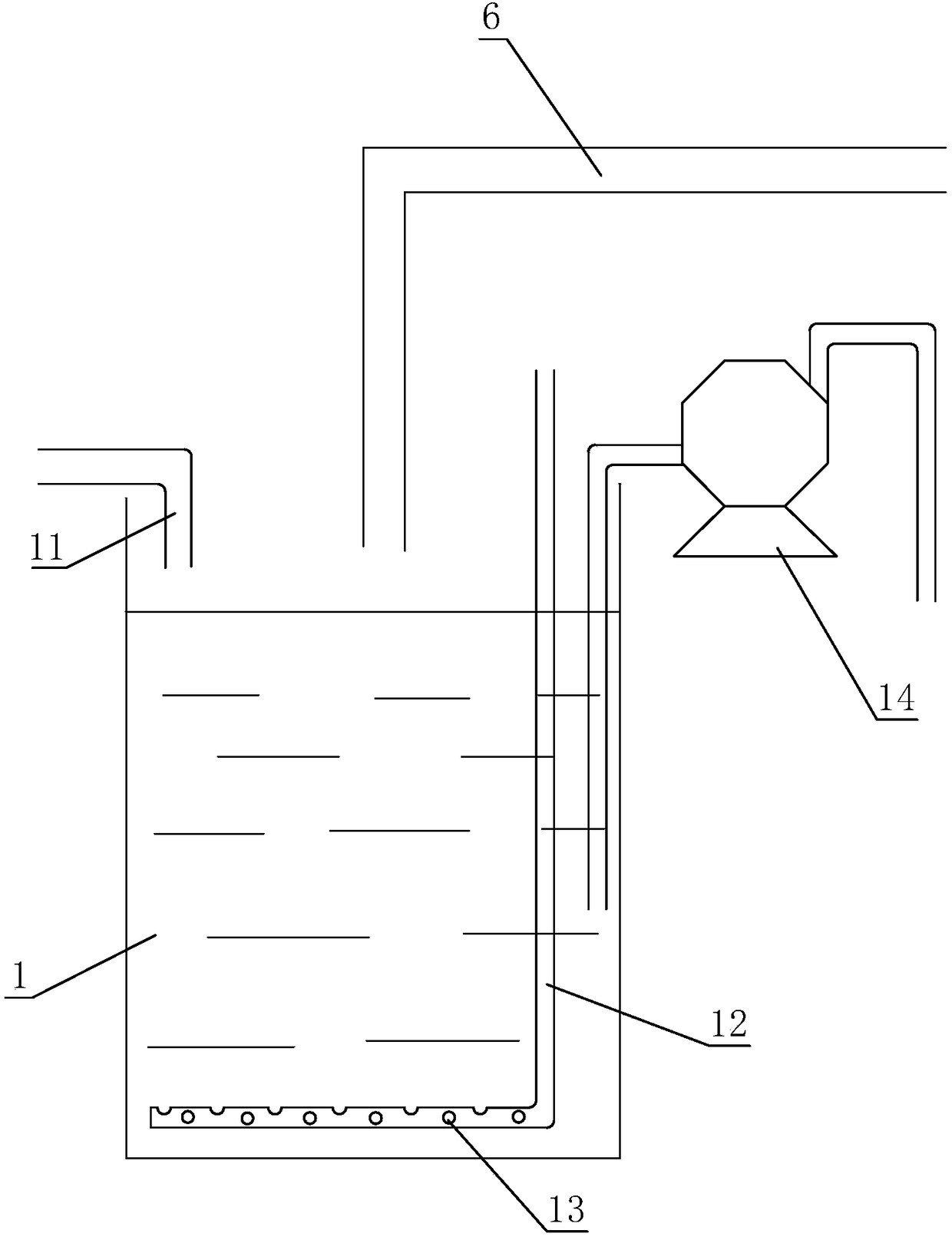

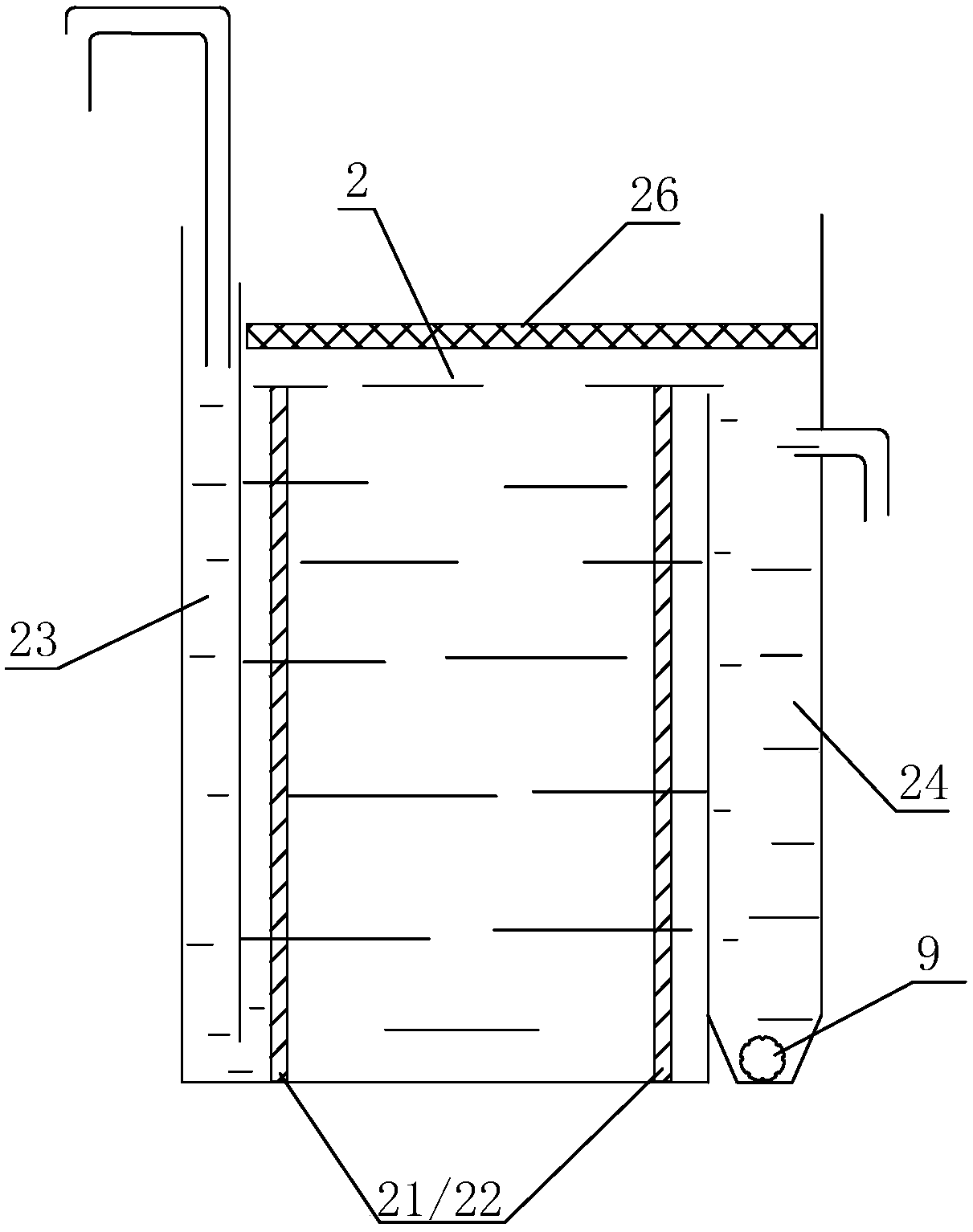

[0038] Such as Figures 1 to 8 As shown, a waste water zero discharge device of the present invention is characterized in that: it comprises a sump 1, an electrocoagulation tank 2, a sedimentation tank 3, a filtration system 4, an ultrafiltration system 5 and a reverse osmosis system 7 connected in sequence through pipelines, The sump 1 is connected to the water inlet pipe 11, the ultrafiltration system 5 and the reverse osmosis system 7 are respectively provided with a waste water outlet pipe 6, the waste water outlet pipe 6 is connected to the sump 1, and the reverse osmosis system 7 is provided with an outlet pipe 71.

[0039] The sump 1 is a PH adjustment pool, and the sump 1 is provided with an aeration stirring tube 12, and one end of the aeration agitation tube 12 is provided with a number of air outlets 13, which are arranged at the bottom of the sump 1, and the other end is an air injection end, which is arranged at the sump 1 upper end.

[0040] A first water pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com