Double-high bar producing device and process

A technology of production equipment and process, which is applied in the field of double-high rod production equipment and process, can solve the problems of low mechanical properties and low output, achieve high output, high rolling speed, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and specific implementation examples.

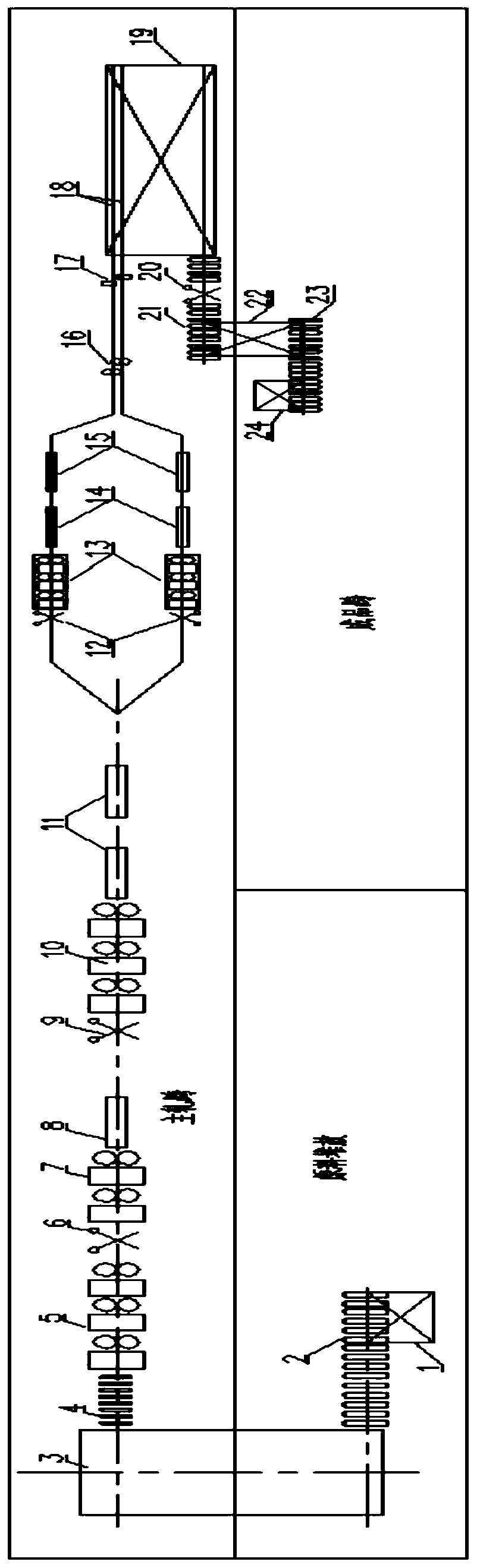

[0027] Such as Figure 1-4 As shown, a double high rod production equipment includes a main rolling span and a finished product span that are connected in sequence. The furnace entry roller table 2 is set at the loading platform 1, and the furnace entry roller table 2 passes through the heating furnace 3 and the main rolling Connected across.

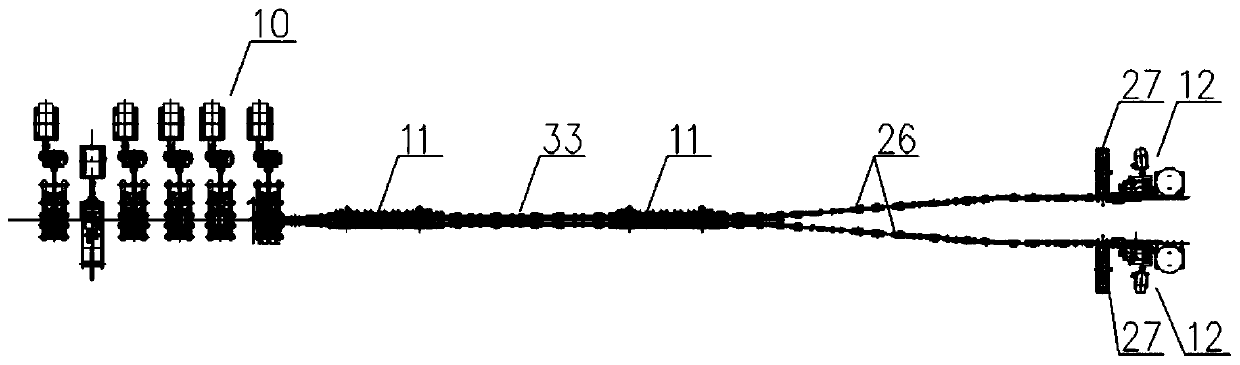

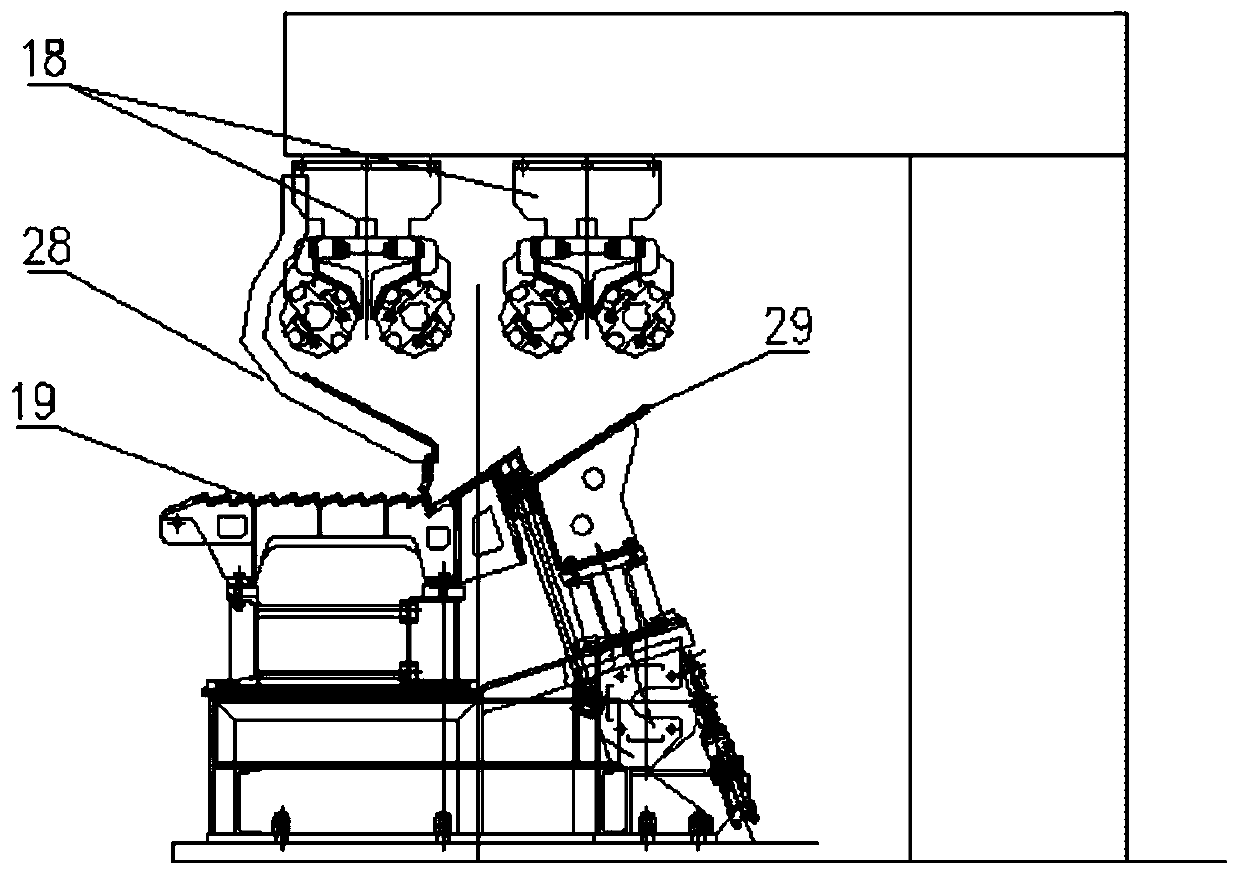

[0028] Among them, the main rolling span includes successively connected tapping roller table 4, rough rolling unit 5, first flying shear 6, intermediate rolling group 7, front end water tank 8, second flying shear 9, finishing rolling unit 10, middle water tank 11, The third flying shear 12, the module rolling mill 13, the middle and rear water tank 14, the end water tank 15, the high-speed flying shear 16, the rod tail brake 17, the double drum 18, the cooling bed 19, the cold shear 20, the first conveyor rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com