Preparation method of raw material powder for high-entropy alloy selective laser melting additive manufacturing

A technology of selective laser melting and high-entropy alloying, which is applied in the field of alloy materials, can solve the problems such as the inability to obtain defect-free printed parts from the elemental mixed powder, the difference of the melting point and boiling point of the elemental powder, and the imperfect powder production system, so as to achieve a good molding effect, The effect of good density and lower production and R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

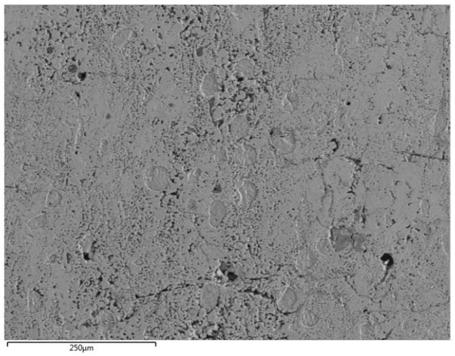

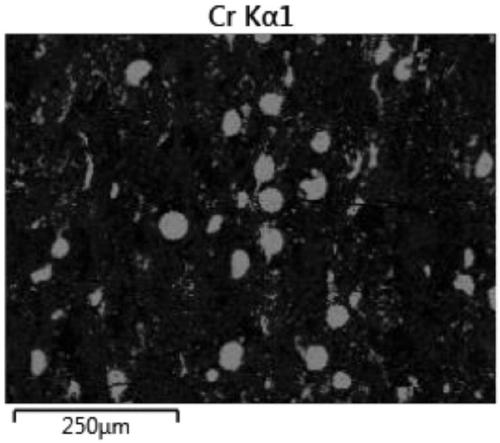

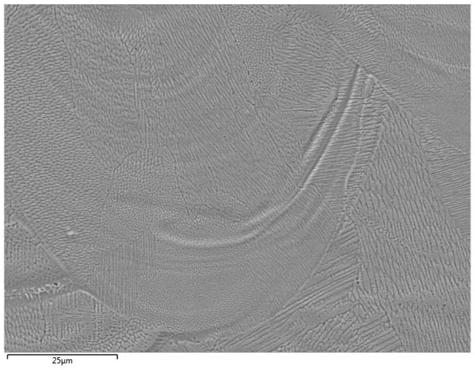

[0039] A FeCoCrNi system high-entropy alloy selective laser melting in-situ additive manufacturing method, comprising the following steps:

[0040] Step 1, the raw materials are mixed, and the purity is 99.9% 560gFe, 590gCo elemental metal spherical powder (powder particle diameter 15~48 microns) and 1110gNi 50 Cr 50 Alloy spherical powder (powder particle size 15-48 microns) is placed in a three-dimensional mixer and mixed for 4 hours, the cylinder speed is 20r / min, and the uniformly mixed spherical powder is dried in a vacuum dryer for 10 hours at a temperature of 50 degrees Celsius , the vacuum degree is less than the absolute pressure of 10KPa, and it is sealed and stored after drying.

[0041] Step 2, additive preparation, the substrate is made of 316L stainless steel, the size is 250×250×15mm, the surface of the substrate is polished with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol respectively. Use...

Embodiment 2

[0053] A FeCoCrNi system high-entropy alloy selective laser melting in-situ additive manufacturing method, comprising the following steps:

[0054] Step 1, the raw materials are mixed, and the purity is 99.9% 560gFe, 590gCo, 442.5gNi elemental metal spherical powder (powder particle size 15-48 microns) and 667.5gNi 20 Cr 80 Alloy spherical powder (powder particle size 15-48 microns) is placed in a three-dimensional mixer and mixed for 2 hours, the cylinder speed is 40r / min, and the uniformly mixed spherical powder is dried in a vacuum dryer for 5 hours at a temperature of 100 degrees Celsius , the vacuum degree is less than the absolute pressure of 10KPa, and it is sealed and stored after drying.

[0055] Step 2, additive preparation, the substrate is made of 316L stainless steel, the size is 250×250×15mm, the surface of the substrate is polished with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol respectivel...

Embodiment 3

[0057] A FeCoCrNi system high-entropy alloy selective laser melting in-situ additive manufacturing method, comprising the following steps:

[0058] Step 1, the raw materials are mixed, and the purity is 99.9% 560gFe, 590gCo, 337.1gNi elemental metal spherical powder (powder particle size 15-48 microns) and 772.9gNi 30 Cr 70 Alloy spherical powder (powder particle size 15-48 microns) is placed in a three-dimensional mixer and mixed for 3 hours, the cylinder speed is 30r / min, and the uniformly mixed spherical powder is dried in a vacuum dryer for 8 hours at a temperature of 80 degrees Celsius , the vacuum degree is less than the absolute pressure of 10KPa, and it is sealed and stored after drying.

[0059] Step 2, additive preparation, the substrate is made of 316L stainless steel, the size is 250×250×15mm, the surface of the substrate is polished with an angle grinder until there is no oxide, and the oil and dirt on the surface are cleaned with acetone and alcohol respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com