Hydrogel evaporation film, preparation method and applications thereof

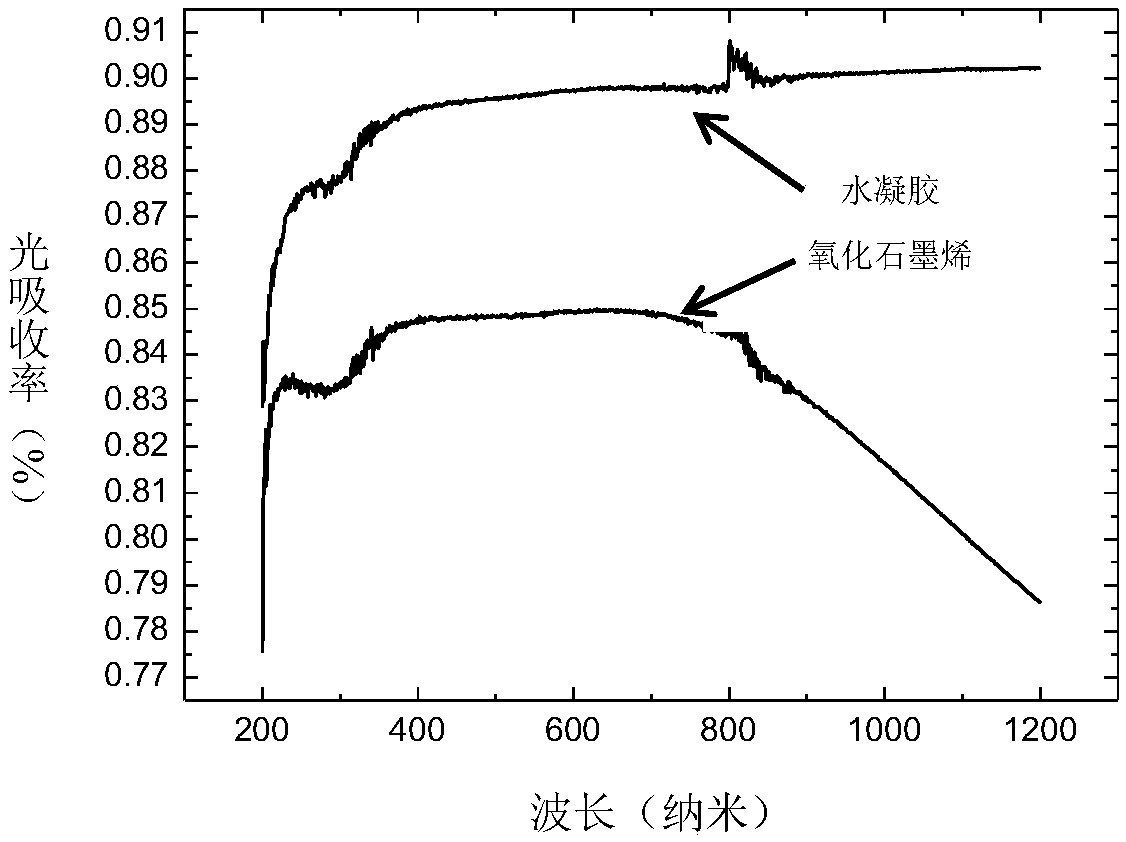

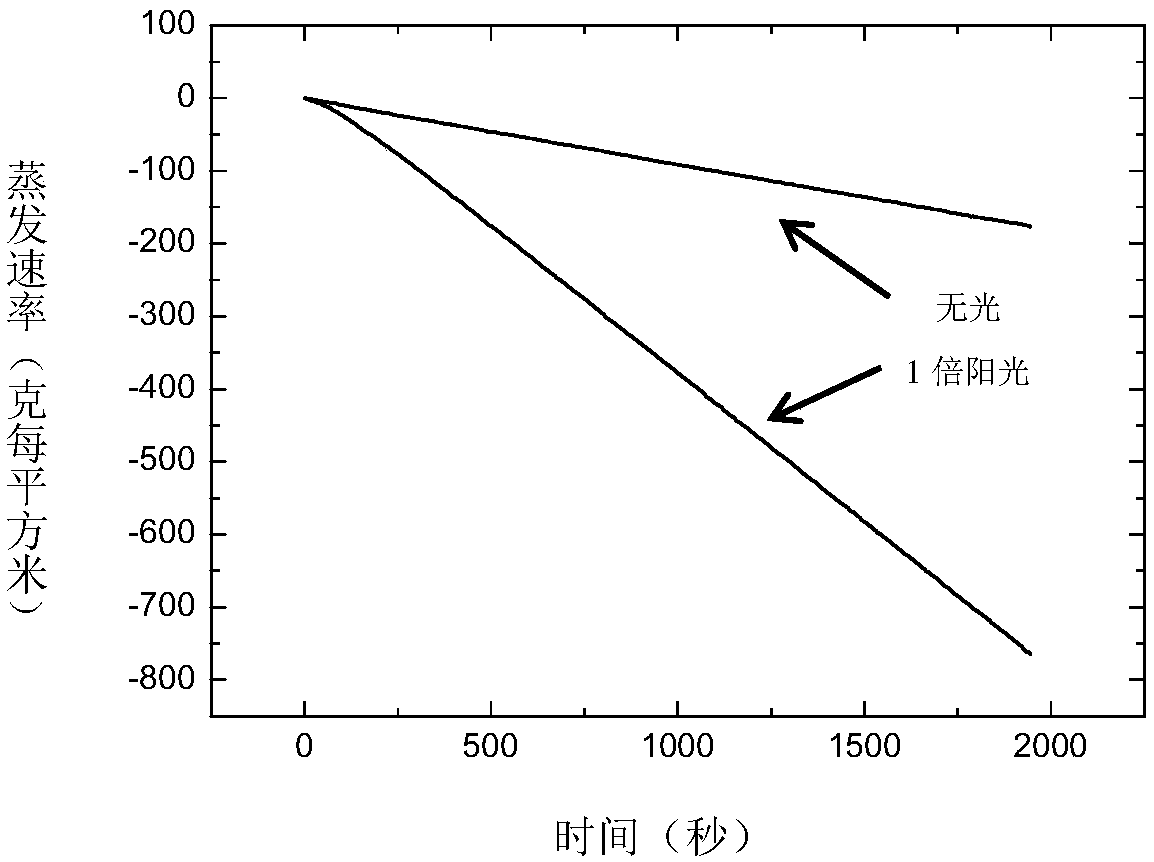

A hydrogel film and hydrogel technology are applied in general water supply conservation, chemical instruments and methods, seawater treatment, etc., which can solve the problem of low carbon evaporation film efficiency, achieve high light absorption rate, and improve evaporation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

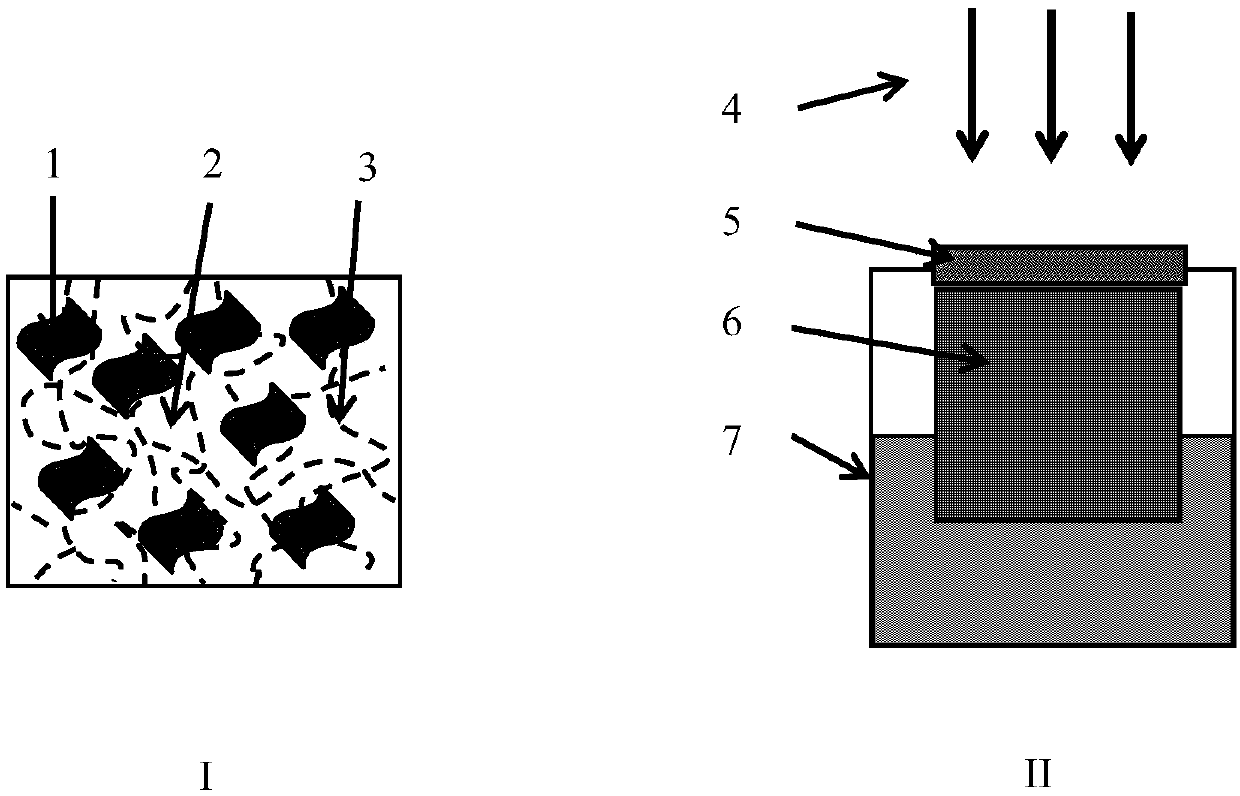

[0041] In a typical implementation of the present invention, 25 mg of graphene oxide, 50 mg of sodium alginate, 100 mg of ascorbic acid and 5 mL of deionized water are mixed, spread on a fast filter paper with a diameter of 6 cm, and left to react overnight. Then drop 2% calcium chloride solution to cross-link and solidify, and a black hydrogel film with a thickness of about 0.5 mm can be formed on the filter paper. Or mix 25mg of graphene oxide, 50mg of sodium alginate and 5mL of deionized water first, spread it flat on a fast filter paper with a diameter of 6cm, drop in 2% calcium chloride solution to cross-link and solidify, and then in 1%-2% ascorbic acid solution Heat and react at 95 degrees Celsius for 1 hour, and a black hydrogel film with a thickness of about 0.5 mm can be formed on the filter paper. Its internal structure is as figure 1 As shown in Figure I, sheet-like graphene 1 is evenly dispersed in hydrogel 2, and a large number of micron-sized water droplets are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com