Unsymmetrical dimethylhydrazine absorbent as well as preparation method and application

A technology of unsymmetrical dimethylhydrazine and absorbent, which is applied in the field of propellant treatment and can solve problems such as unsatisfactory absorption effect and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

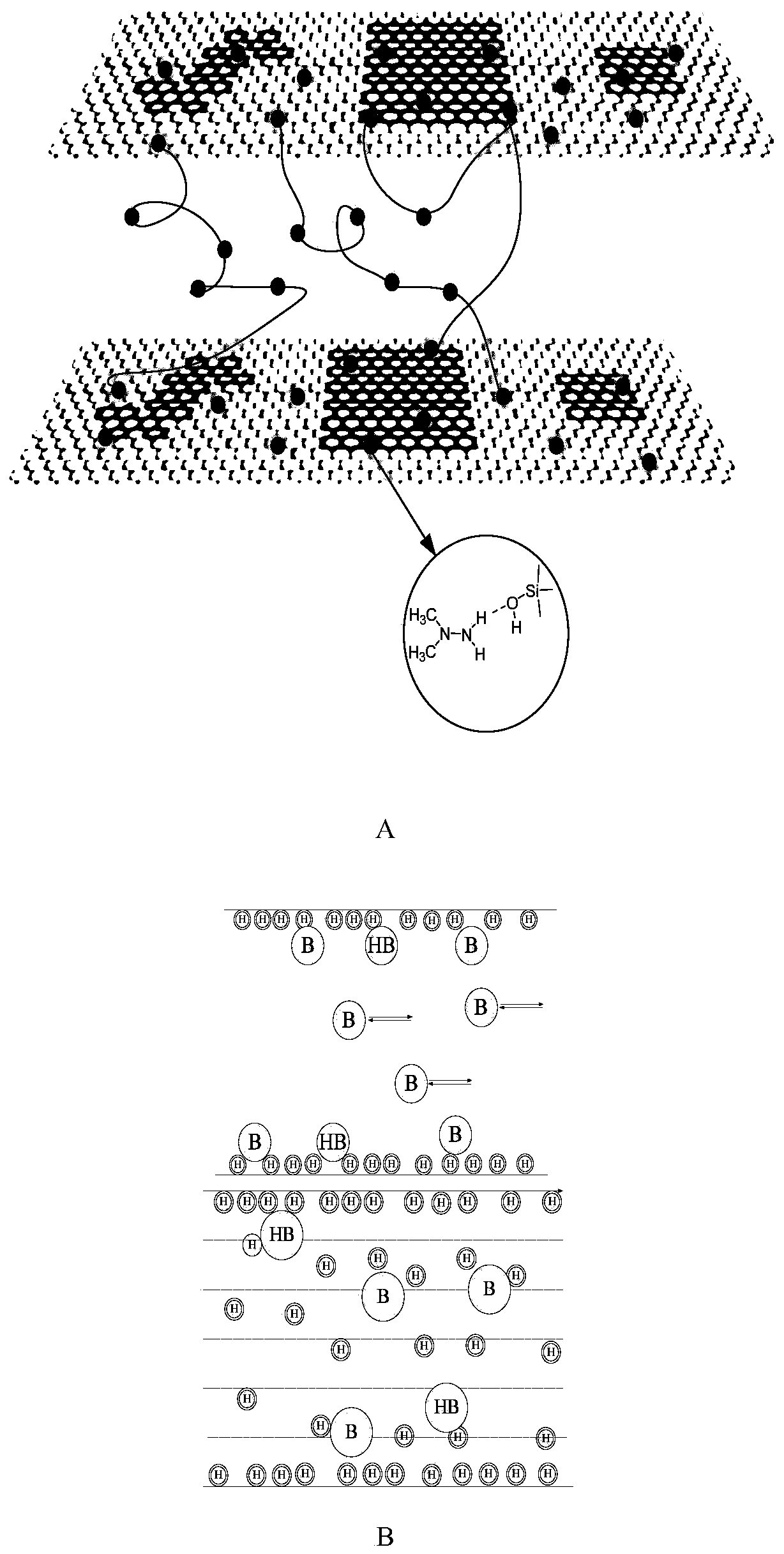

[0027] A kind of preparation method of unsymmetrical dimethylhydrazine absorbent, described unsymmetrical dimethylhydrazine absorbent comprises A component and B component, and preparation method comprises the steps:

[0028] Preparation of component A: Weigh 3g CTAB and dissolve it in 100ml of deionized water, take 100ml of graphene dispersion and 200ml of nanocellulose solution, mix them evenly and add them to a 500ml three-necked flask, use NaOH to adjust the pH of the solution to 8.5 to obtain a mixed solution, and 14ml tetraethyl orthosilicate is added dropwise in the described mixed solution with the speed of 1~2d / s, wherein, mass ratio graphene: nanocellulose: tetraethyl orthosilicate=1:4:25, at 40 Stir at °C for 24 hours, filter the reaction slurry with suction to obtain a filter cake, wash with ethanol three times, and vacuum-dry at 60°C for 24 hours to obtain component A.

[0029] Preparation of component B: select commercialized D113 macroporous weakly acidic cation...

Embodiment 1

[0040] Embodiment 1: the preparation of unsymmetrical dimethylhydrazine adsorbent A component

[0041] Weigh 3g of CTAB and dissolve it in 100ml of deionized water, take 100ml of graphene dispersion (aqueous solution), 200ml of nanocellulose solution, mix them evenly and add them to a 500ml three-necked flask, use NaOH to adjust the pH of the solution to 8.5, and mix 14ml of orthosilicon Ethyl acetate was added dropwise to the above mixed solution at a rate of 1-2d / s, stirred at 40°C for 24h, the resulting slurry was suction filtered to obtain a filter cake, washed with ethanol three times, and vacuum-dried at 60°C for 24h. Obtain the A component. (mass ratio graphene: nanocellulose: tetraethyl orthosilicate=1:4:25)

Embodiment 2

[0042] Embodiment 2: the preparation of unsymmetrical dimethylhydrazine adsorbent B component

[0043] Commercialized D113 macroporous weakly acidic cation exchange resin was selected. In the pretreatment process, first use deionized water to soak and wash the water until the water is clear without turbidity, then use 3% NaOH to soak for 3 hours, pour off the lye, and use deionized water to wash Rinse the resin until it is neutral, preferably soak it in 5% HCl solution for 6 hours, pour off the acid solution, and wash it with deionized water until it is neutral.

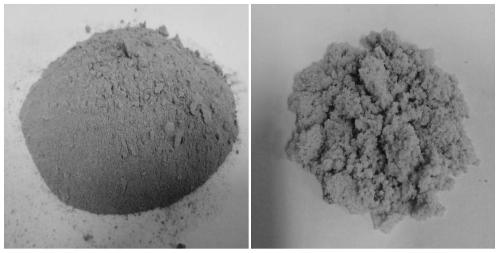

[0044] color appearance

[0045] The unsymmetrical dimethylhydrazine absorbent consists of two components, A and B, component A is gray-black fibrous particles, and component B is light yellow particles, such as figure 2 shown.

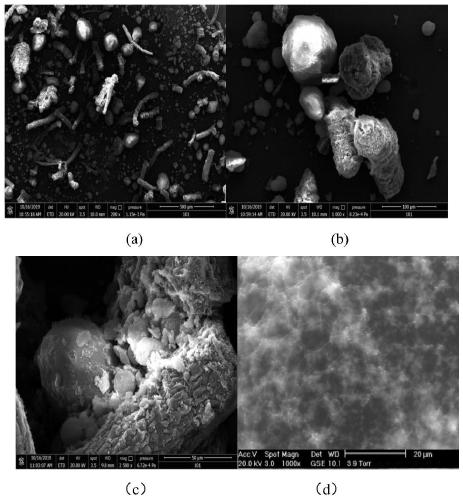

[0046] SEM

[0047] The characterization morphology of graphene-based UDM absorbent composites was observed by emission electron microscopy. Depend on image 3 In (a), it can be seen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com