Sludge drying machine energy-saving consumption-reducing and waste gas zero-emission system and method based on zero-emission framework

A sludge drying and zero-emission technology, which is applied in the chemical industry, organic fertilizers, climate sustainability, etc., can solve problems such as disturbing residents and unsatisfactory treatment effects of deodorization equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

[0016] Now carry on the concrete description to this scheme systematically.

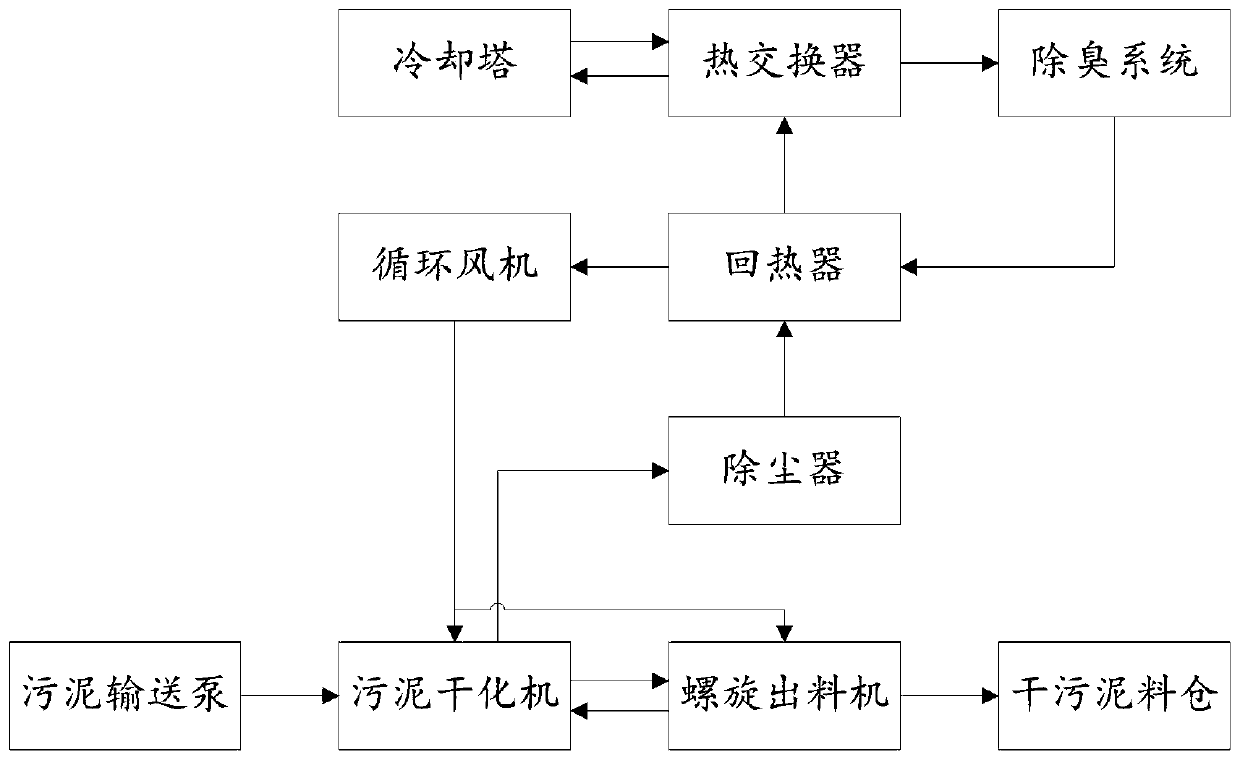

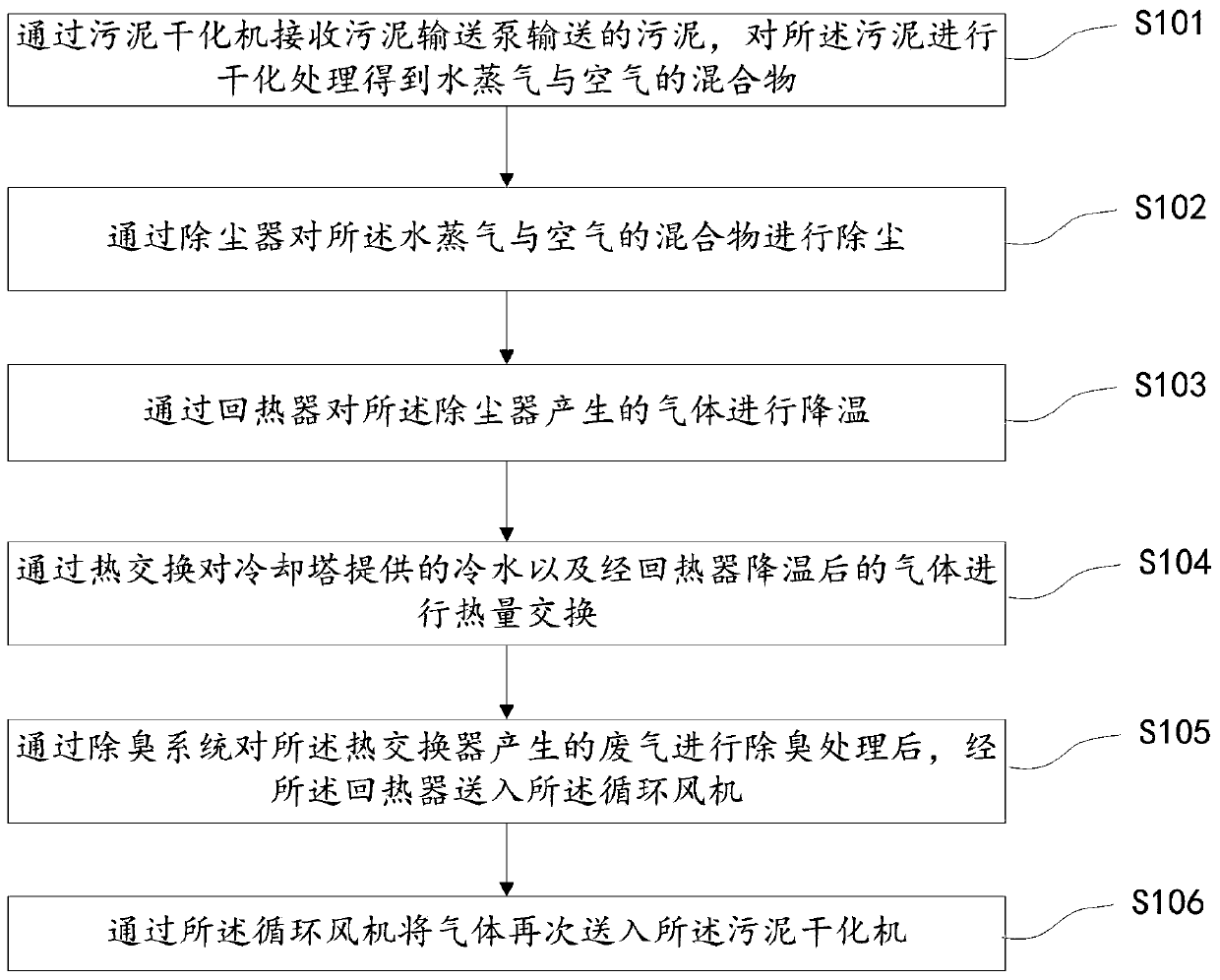

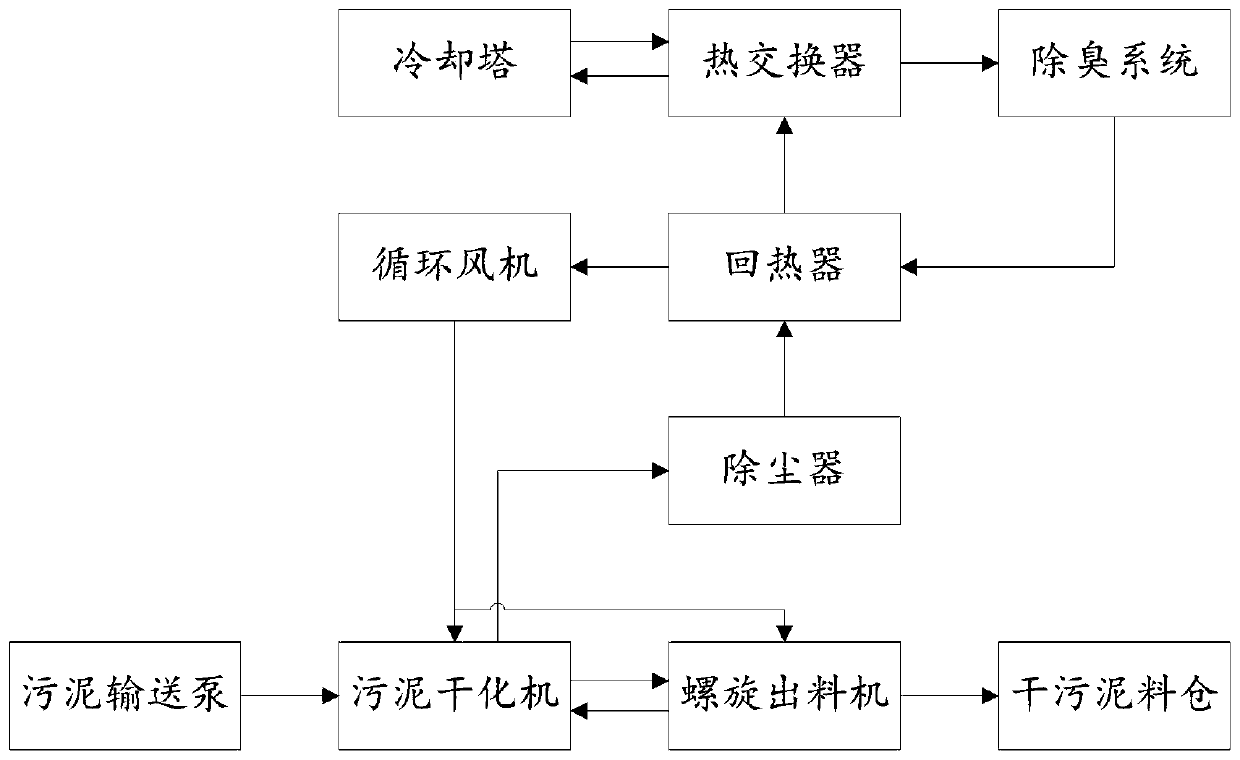

[0017] figure 1 A structural block diagram of a sludge dryer energy saving and consumption reduction and exhaust gas zero emission system based on a zero-emission architecture provided by an embodiment of the present invention. Such as figure 1 As shown, the system includes:

[0018] Sludge drying machine 101, screw discharge machine 102, dust collector 103, regenerator 104, circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com