Preparation method of alcohol-induced low-alkali konjak gel

A gel and konjac technology, which is applied in the field of preparation of alcohol-induced low-alkali konjac gel, can solve the problems of high water separation rate, syneresis, increased alkali dosage, etc., and achieves lower gelling temperature, lower dosage, and lower swelling. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples. The methods are conventional methods unless otherwise specified. The materials can be obtained from public commercial sources unless otherwise specified.

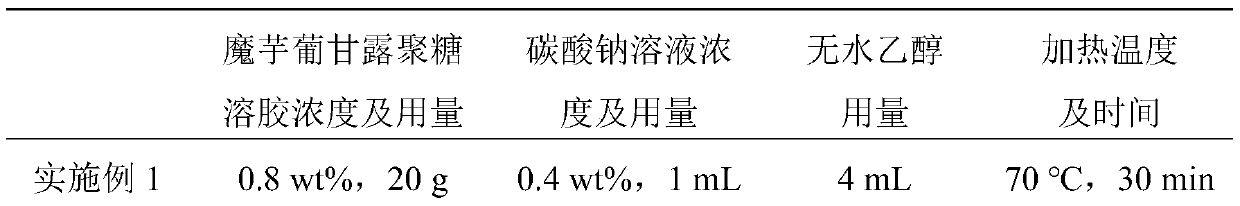

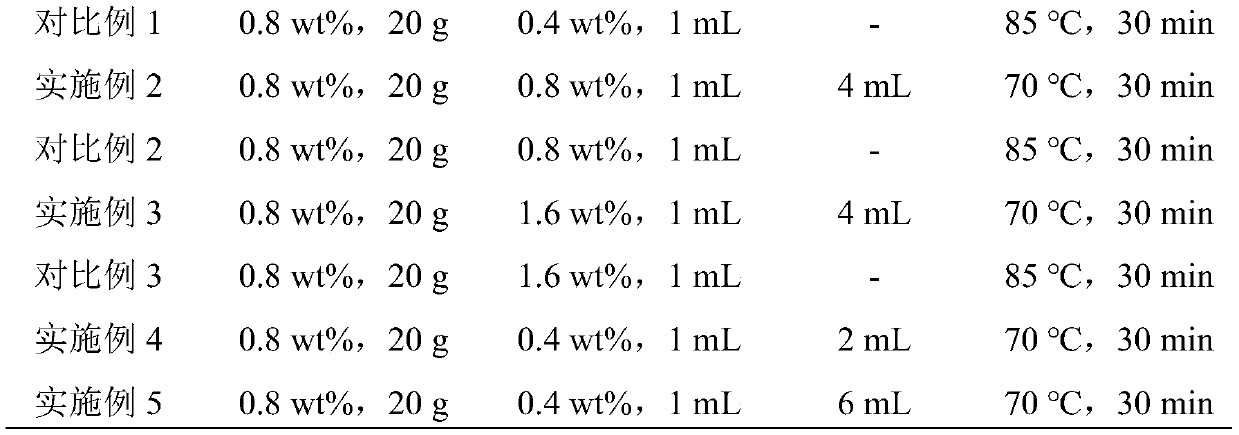

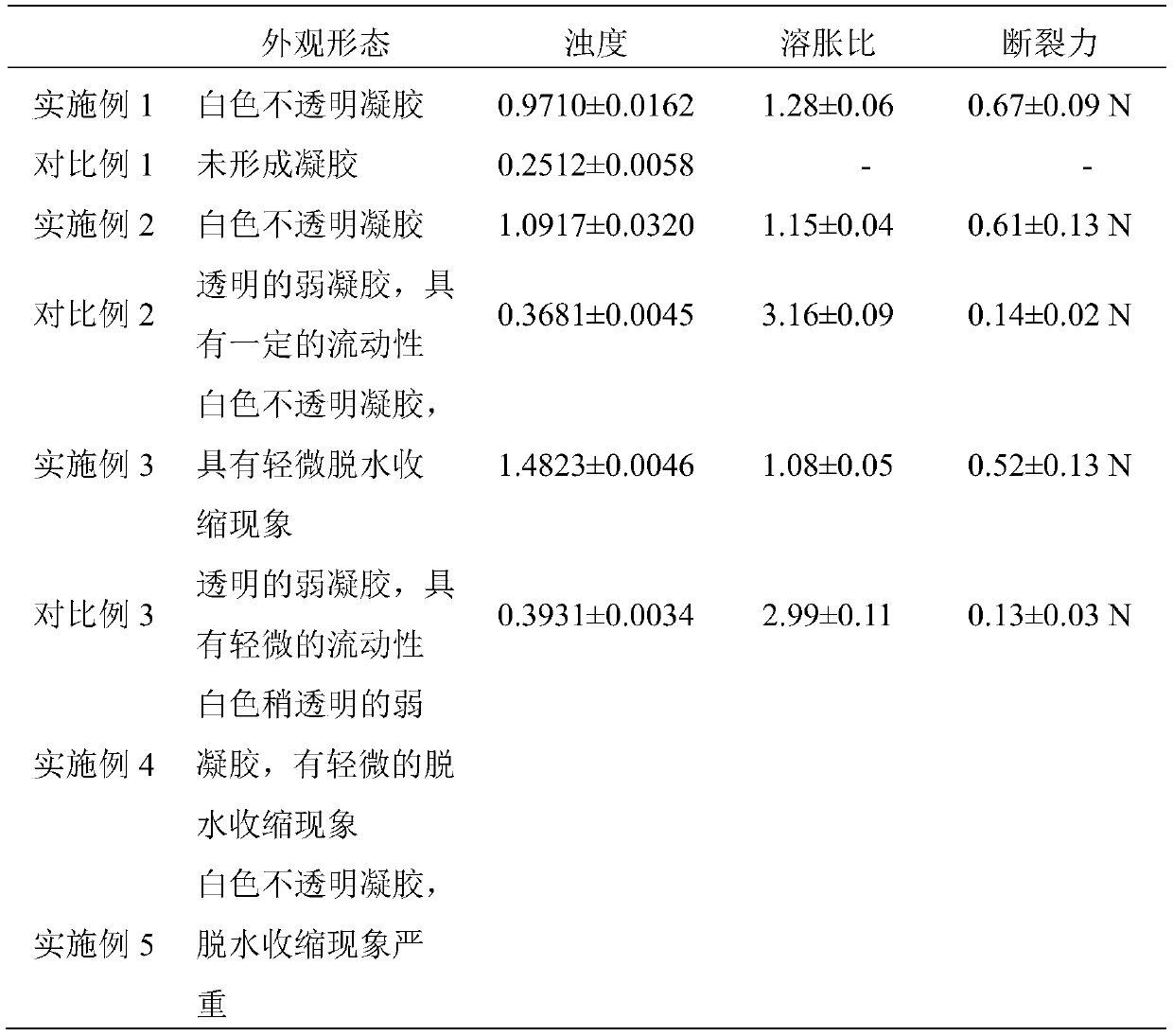

[0018] The parameters used in embodiment and comparative example are shown in Table 1, and the operation process is as follows:

[0019] (1) konjac glucomannan sol (hereinafter referred to as "konjac sol") with a mass concentration of 0.8% was configured, and stirred for 12 hours to make it fully swell;

[0020] (2) Take 20 g of the sol prepared in step 1), add 1 mL of prepared sodium carbonate solution with different mass concentrations, and stir for 2 minutes;

[0021] (3) Slowly add dehydrated ethanol to the mixture obtained in the step 2) twice, adding 2 mL each time, stirring for 3 minutes each time. Comparative example does not add dehydrated alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com