A control method for ds inclusions in medium-carbon sulfur-containing aluminum deoxidized non-quenched and tempered steel

A non-quenched and tempered steel and control method technology, applied in the field of control of Ds inclusions in medium-carbon sulfur-containing aluminum deoxidized non-quenched and tempered steel, can solve the problems of reducing production rhythm, inapplicability, and affecting the castability of molten steel, and achieve High removal efficiency, strong stirring effect, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

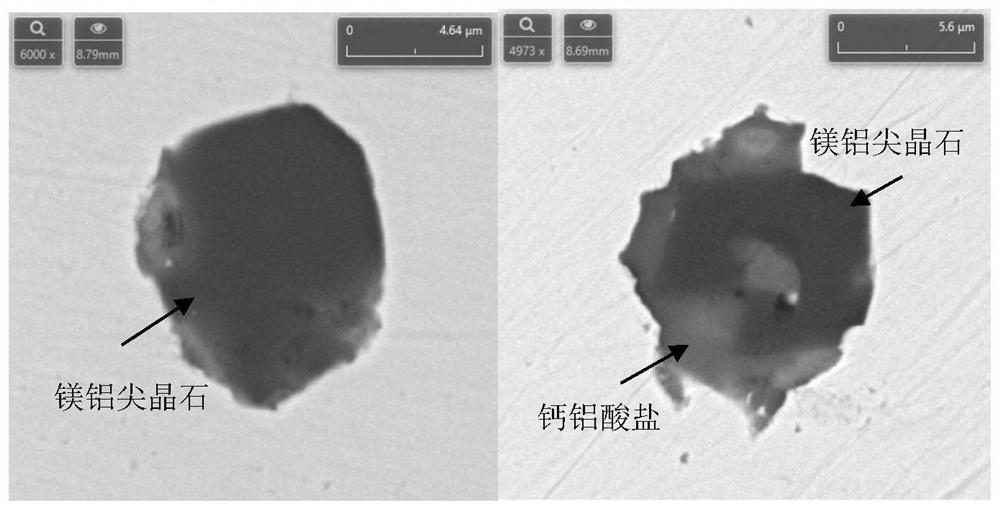

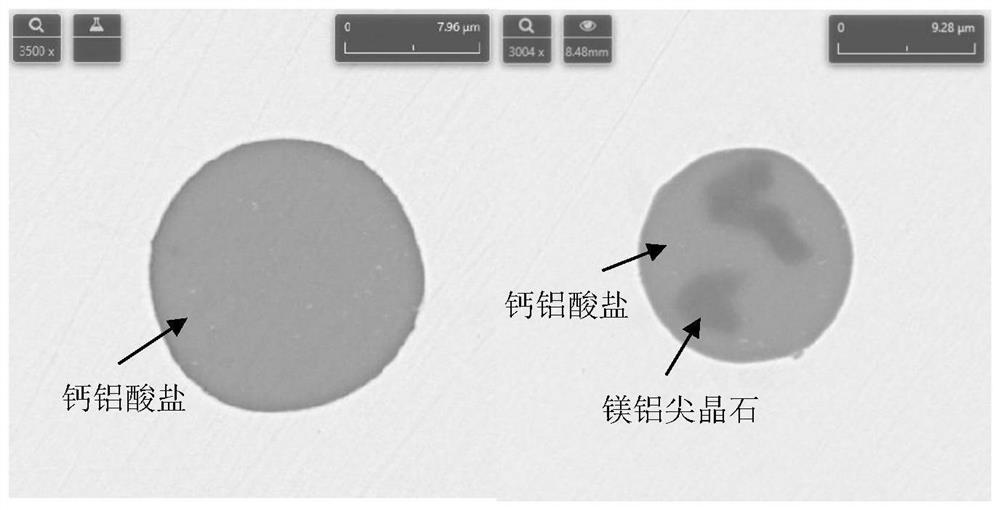

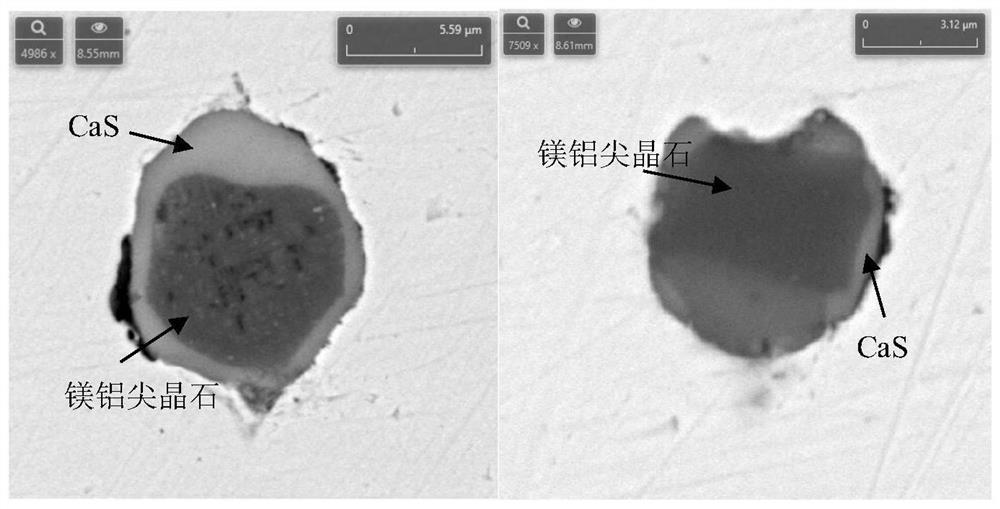

Image

Examples

Embodiment 1

[0034] This example uses the production process of non-quenched and tempered steel for sulfur-containing S45C shafts to illustrate the actual control effect of the present invention on Ds-type inclusions, and the content that is not specified is the conventional smelting process of sulfur-containing S45C.

[0035] Composition: C 0.46%, Si 0.25%, Mn 0.81%, S 0.028%, Al 0.018%, O 7.2ppm

[0036] (1) Converter smelting: 130t of converter steel, 0.08% C content, 0.020% S content, 1.0kg / t deoxidizer aluminum cake, silicon manganese alloy, silicon ferrosilicon alloy, vanadium iron alloy, recarburizer And 500kg lime + 300kg slagging agent.

[0037] (2) LF refining: energize the slag, take the initial sample to measure the composition of molten steel, adjust the aluminum content to 0.040%, and do not allow further adjustment of Al in the later stage of refining; the slag surface is diffused and deoxidized, and the slag composition is shown in Table 1; the S content of molten steel 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com