FRP truss joint structure and implementation method thereof

A node structure and truss technology, which is applied to truss structures, truss beams, building structures, etc., can solve the problems of asynchronous colloid and bolt stress, and high requirements for component surface treatment, so as to achieve high construction efficiency and less welding workload , the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but it should not be understood as a limitation of the protection scope of the present invention.

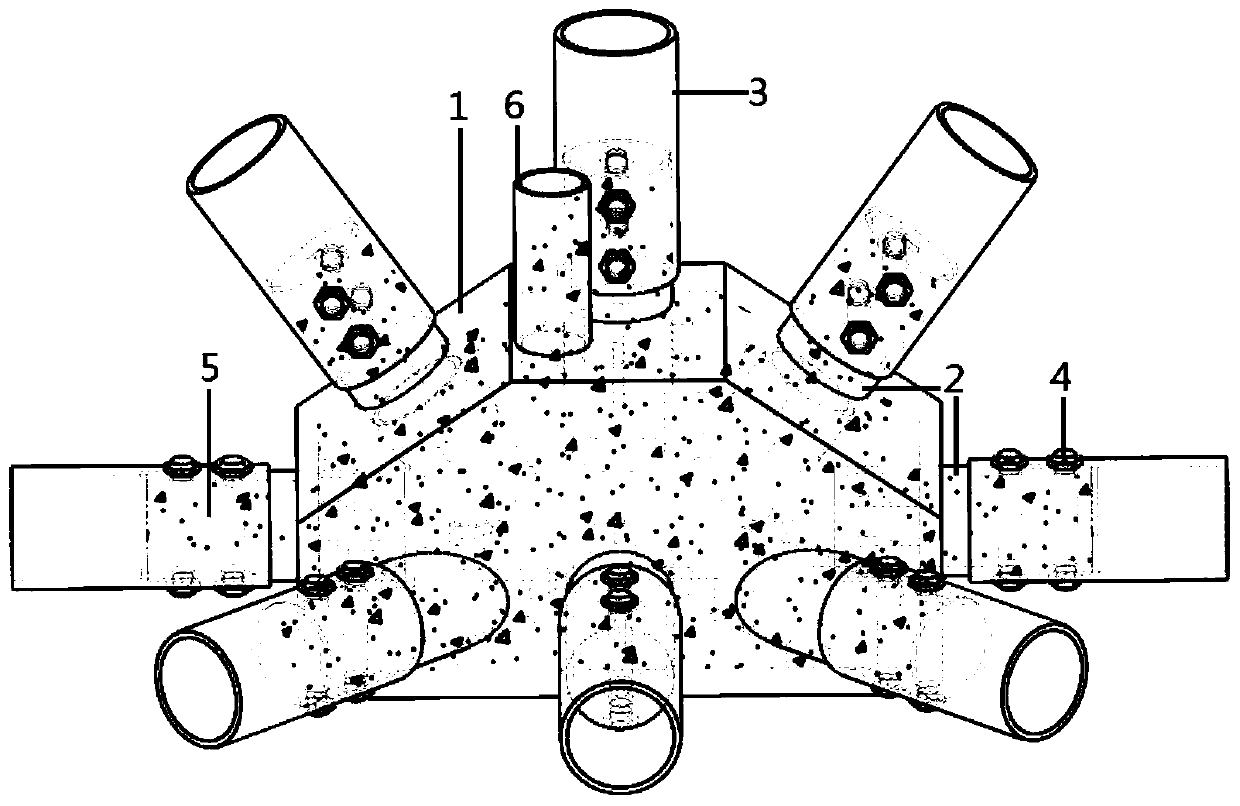

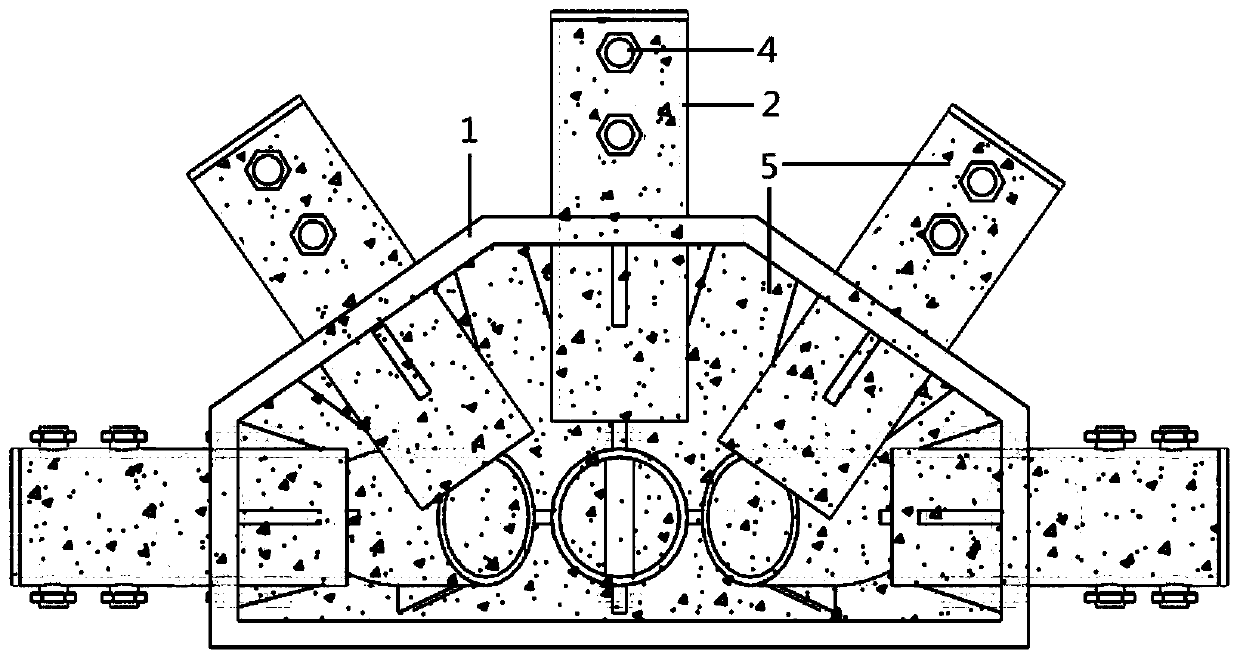

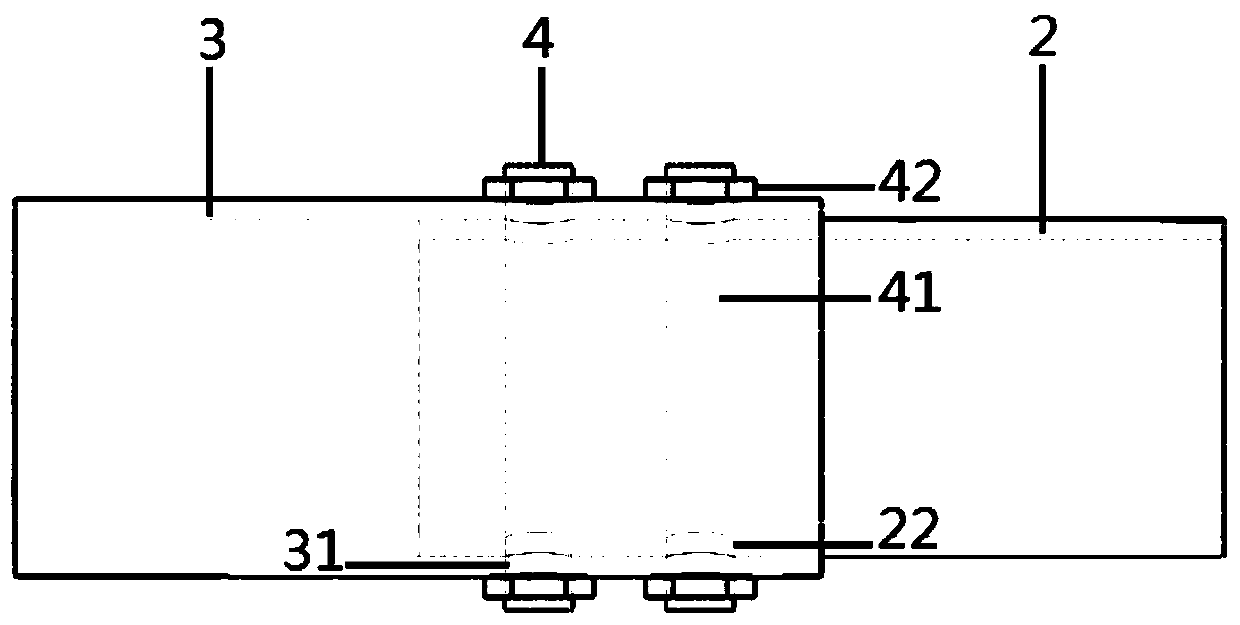

[0035] Such as Figure 1-4 As shown: a FRP truss node structure implemented in this implementation includes a steel box 1, a steel pipe 2 inserted into the steel box 1 at one end, an FRP pipe 3 with the same inner diameter as the outer diameter of the steel pipe 2, and a bolt for connecting the steel pipe 2 and the FRP pipe 3 Nail 4, micro-expansion concrete 5 poured into the steel box 1 and steel pipe 2, conduit 6 for pouring micro-expansion concrete 5 into the steel box 1 and steel pipe 2.

[0036] The steel box 1 has a plurality of tunnels 11 , wherein the number, shape and size of the tunnels 11 are determined according to the number, shape and size of the steel pipes 2 and the conduits 6 .

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com