Low-temperature cracking and caving method of hard roof in coal mine goaf

A technology of hard roof and goaf, which is applied in the fields of fluid extraction, ground mining, earth-moving drilling, etc., can solve the problems of poor adaptability in small underground spaces, easy gas accumulation, and bulky volume, etc. cracking effect, the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with an embodiment in the accompanying drawings, the present invention will be further described:

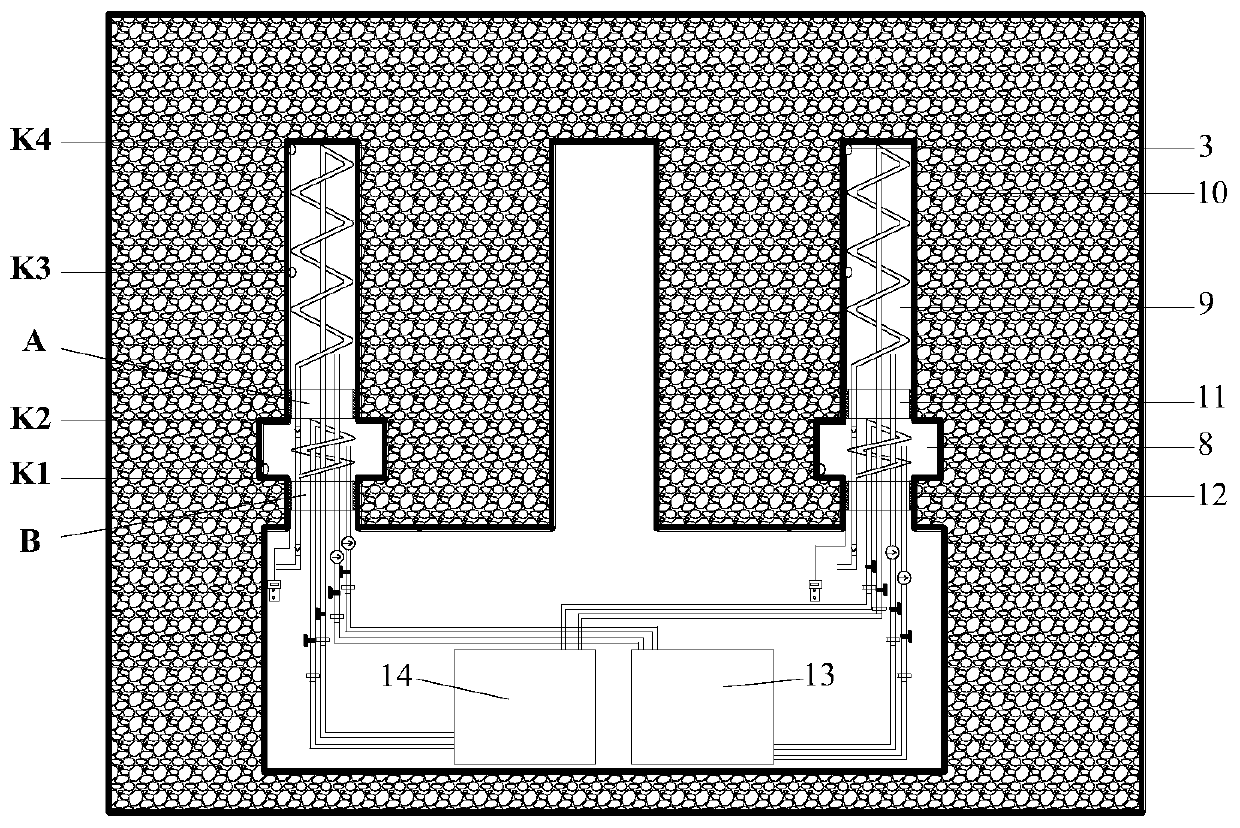

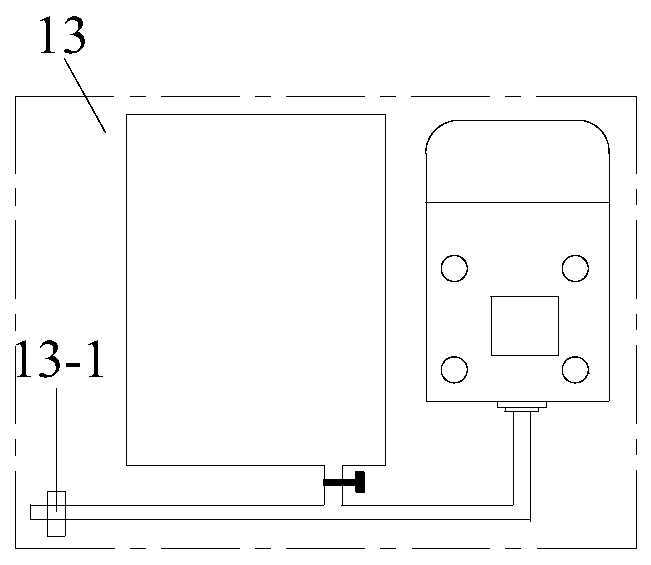

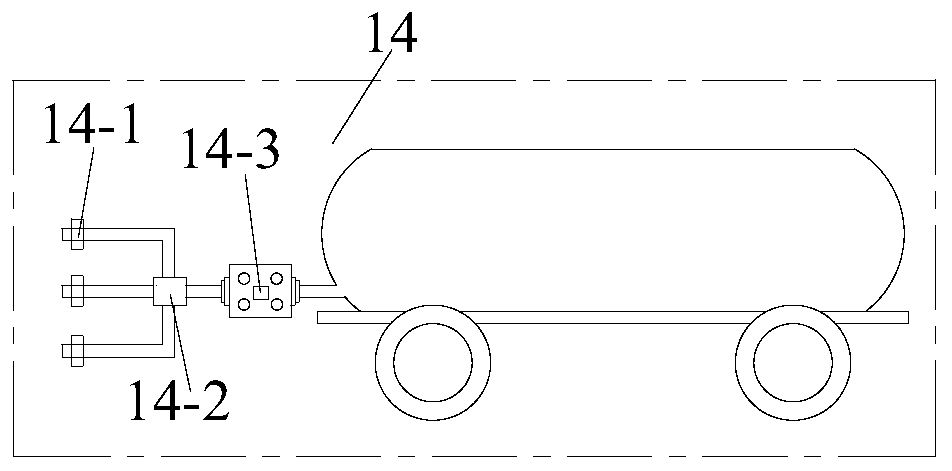

[0032] Such as Figure 1-Figure 6 and Figure 9 As shown, the method for low-temperature fracturing and caving of hard roofs in goafs of coal mines of the present invention includes digital display thermometers 1, temperature sensors 3, water injection pipes, cryogenic fluid freezing pipes, capsule hole sealers, high-pressure water injection systems 13 and Cryogenic fluid tank car 14, the specific steps of its low-temperature fracturing roofing method are as follows:

[0033] a. Construction drilling: sequentially construct a plurality of fracturing boreholes 9 and an empty hole 16 to the hard roof of the goaf. The hole diameter is 80mm, and the distance between adjacent fracturing boreholes 9 is 1-2m. The diameter of the one empty hole 16 is 2-3 times of the diameter of the fracturing drill hole. There are four fracturing boreholes 9 in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com