Rapid aluminum melting furnace capable of continuously discharging aluminum

An aluminum melting furnace, fast technology, applied in the direction of furnace, charge, crucible furnace, etc., can solve the problems of difficult loading of raw materials into the furnace, difficult collection, development constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be further described in detail below.

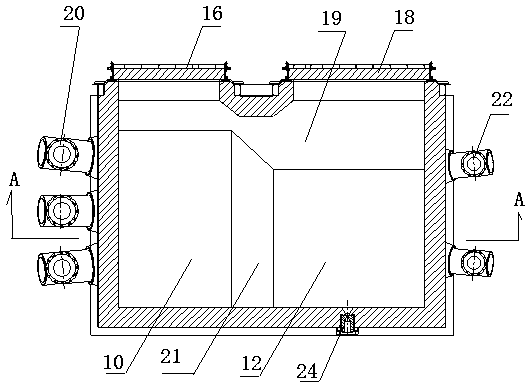

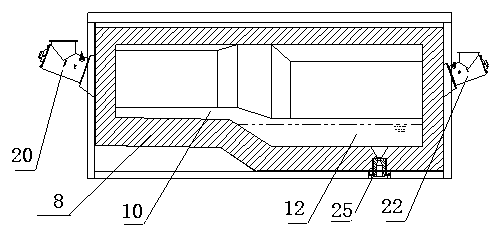

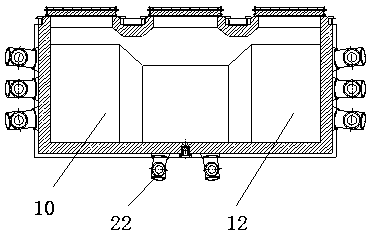

[0029] Such as Figure 1 to Figure 2 As shown, the continuous aluminum-melting rapid aluminum melting furnace designed in the first embodiment of the present invention adopts a double-chamber furnace structure, including a hollow furnace body 8, and a design scheme of high and low melting pools is adopted in the furnace body 8, and the high melting pool is a melting chamber 10. It is specially used to put in solid recycled aluminum raw materials; the low melting pool is the soup storage room 12, which is specially used to store the melted aluminum melt. The high and low melting pools are connected with a stepped structure. Confirm; the edge of the melting chamber 10 is provided with a guide surface 21 extending obliquely to the bottom of the soup storage chamber 12, which can slow down the speed of the molten aluminum flowing down and avoid splashing.

[0030] The depth of the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com