Method for improving milling stability domain of titanium alloy thin-walled workpiece

A technology for titanium alloy and thin-walled parts is applied in the field of improving the milling stability field of titanium alloy thin-walled parts, which can solve the problems of insufficient theoretical research, and it is difficult to completely separate the tool and the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

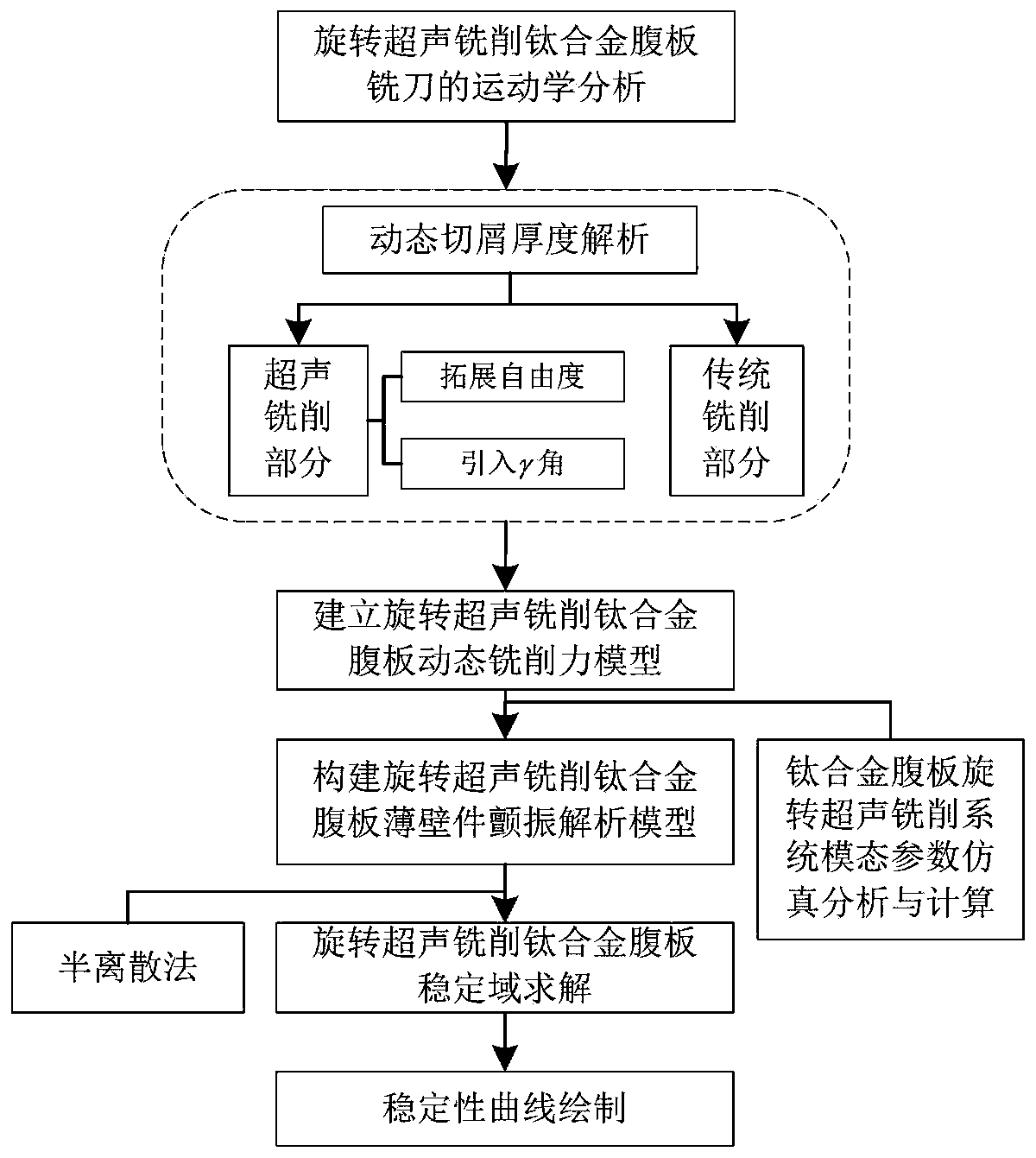

Method used

Image

Examples

Embodiment 1

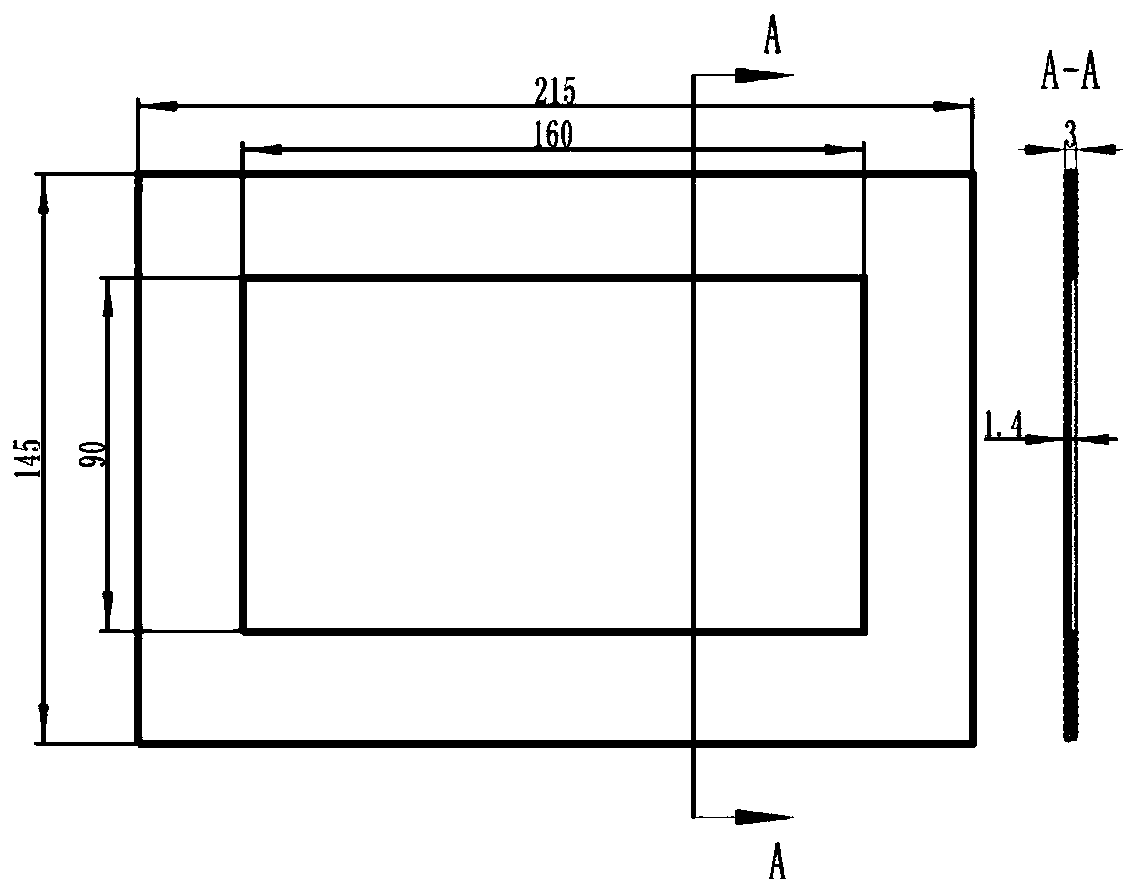

[0222] In this example, the MCV-L850 machining center is used to study the influence of rotary ultrasonic machining technology on the milling stability domain of milling titanium alloy thin-walled plates. The schematic diagram of the structure is as follows image 3 shown. The overall size of the titanium alloy web is 215 mm × 145 mm × 3 mm. The tool used in the milling experiment is a three-tooth carbide end mill with a diameter of 8 mm and a helix angle of 35°. From the milling force measured by the slot milling experiment, the average milling force coefficient of the cemented carbide cutter with no ultrasonic milling titanium alloy web is obtained, as shown in Table 1. The processing parameters (feed speed, depth of cut, etc.) of titanium alloy thin-walled parts are generally small. Therefore, the effects of material removal and tool position changes on machining stability during milling of titanium alloy webs are ignored. The specific modal parameters are obtained by ANA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com