C# catalyst production process energy management and control system

A technology for management and control systems and production processes, applied in database management systems, manufacturing computing systems, structured data retrieval, etc., to solve problems such as low catalyst production efficiency, inability to communicate equipment operation information, and weak production process control, and to improve The effect of catalyst production work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

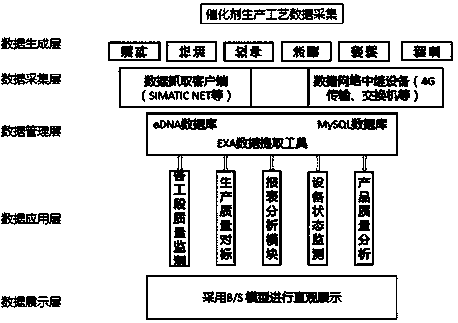

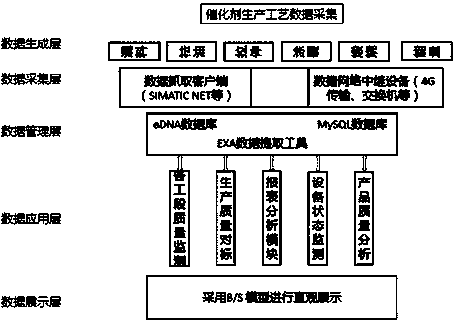

[0019] The present invention has designed a kind of C# catalyst production process energy control system, such as figure 1 As shown, it includes the data generation layer, data acquisition layer, data management layer, data application layer, and data display layer; among them, the data generation layer is used to obtain the production data of each section of catalyst production. In practical applications, it specifically includes the production of each section of catalyst production. The data include the set temperature, actual temperature, mesh belt drive motor speed, and combustion fan speed in the calcination area; the linear speed, roller speed, roller gap, and paste temperature in the coating area; The set value and actual value of ionized water and glass fiber; the data acquisition layer is connected to the data generation layer, and the data acquisition layer is used to collect the control logs of each section of catalyst production and receive the production data of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com