Dry red wine oak barrel malolactic fermentation process

A malolactic acid and dry red wine technology, which is applied in the preparation of wine, the preparation of alcoholic beverages, microorganisms and other directions, can solve the problem of no aroma fermentation process and other problems, so as to improve the smell quality, protect the color, and reduce the total acidity. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

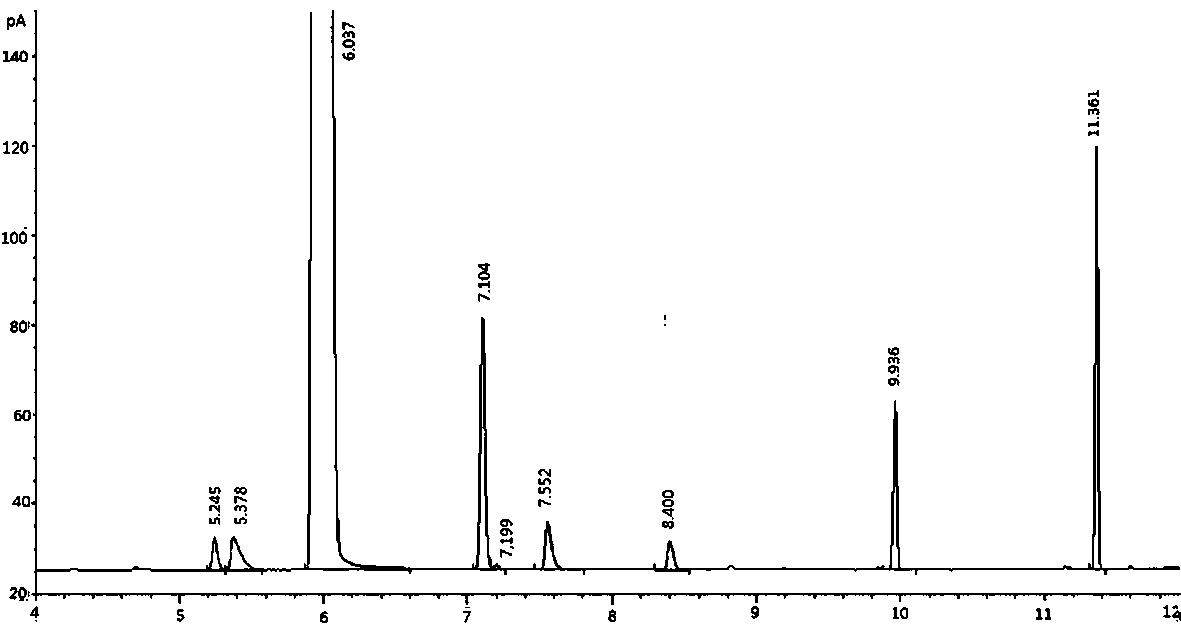

Image

Examples

Embodiment 1

[0028] A dry red wine oak barrel malolactic fermentation process, its specific scheme is as follows:

[0029] Detect the residual sugar content of the grape must. When the residual sugar content is 21g / L, inoculate 0.0005g / L lactic acid bacteria and control the temperature at 23.5°C; when the residual sugar content is 3.4 / L, separate the artesian wine and put the artesian wine into oak The barrel continued to carry out malolactic fermentation, and according to the amount of 0.6g / L, fresh untoasted oak chips were added to the artesian wine, the temperature was controlled at 20.4°C, and the fermentation was carried out for 30 days. Filter through a flat ceramic membrane with a pore size of 0.65 μm and high permeation flux, then inspect the physical and chemical indicators and sensory indicators, and finally put the wine into the container and seal it.

[0030] The flat ceramic membrane of described high permeation flux, its preparation method is:

[0031] Mix 100g ceramic powde...

Embodiment 2

[0037] A dry red wine oak barrel malolactic fermentation process, its specific scheme is as follows:

[0038] Detect the residual sugar content of the grape must. When the residual sugar content is 25g / L, inoculate 0.001g / L lactic acid bacteria and control the temperature at 24°C; when the residual sugar content is 3.7g / L, separate the artesian wine and put the artesian wine into The oak barrels continued to carry out malolactic fermentation, and according to the amount of 0.9g / L, fresh untoasted oak chips were added to the artesian wine, the temperature was controlled at 22.1°C, and the fermentation was carried out for 35 days. During this period, the barrel was stirred every 3 days. A flat ceramic membrane with a filter pore size of 0.71 μm and high permeation flux is selected for filtration, and then the physical and chemical indicators and sensory indicators are tested, and finally the wine is put into the container and sealed.

[0039] The flat ceramic membrane of describ...

Embodiment 3

[0047] A dry red wine oak barrel malolactic fermentation process, its specific scheme is as follows:

[0048] Detect the residual sugar content of the grape must. When the residual sugar content is 25g / L, inoculate 0.002g / L lactic acid bacteria and control the temperature at 26.5°C; when the residual sugar content is 5.8g / L, separate the artesian wine and put the artesian wine into The oak barrels continued to carry out malolactic fermentation, and according to the amount of 1.0g / L, fresh untoasted oak chips were added to the artesian wine, the temperature was controlled at 21°C, and the fermentation was carried out for 40 days. During this period, the barrel was stirred every 5 days. A flat ceramic membrane with a filter pore size of 0.85 μm and high permeation flux is selected for filtration, and then the physical and chemical indicators and sensory indicators are tested, and finally the wine is put into the container and sealed.

[0049] The flat ceramic membrane of describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com